Preparation method for salt-tolerant ultra-high molecular weight thickening agent

An ultra-high molecular weight, thickener technology, applied in the chemical industry, which can solve the problems of collapse, weakened thickening effect, and reduced hydrodynamic volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

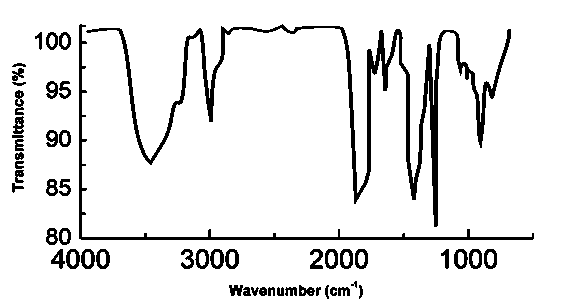

Image

Examples

Embodiment 1

[0020] Example 1 Preparation of salt-tolerant ultra-high molecular weight thickener

[0021] Dissolve 2-methyl-2-acrylamidopropanesulfonic acid and acrylamide in water at a mass ratio of 1:1:4, then under ice bath conditions, control the system temperature at 5°C, and slowly add it dropwise while stirring Ammonia solution to control the pH value of the system at 6.5; then mix the emulsifier Span-80 and kerosene at a ratio of 1:4 and stir. After the Span-80 is completely dissolved in the kerosene, slowly add the mass ratio of the kerosene 1:1 octadecyl acrylate, stir to dissolve; add the kerosene solution to the neutralized aqueous solution, emulsify at room temperature and at a stirring speed of 1200 rpm for 40 minutes, then add the mass of kerosene Ammonium persulfate with a ratio of 1: 140 was heated up to 60°C and reacted for 2 hours under the protection of nitrogen. Finally, Tween-80 with a mass ratio of 1:1 to kerosene was added and reverse emulsified for 50 minutes. Sal...

Embodiment 2

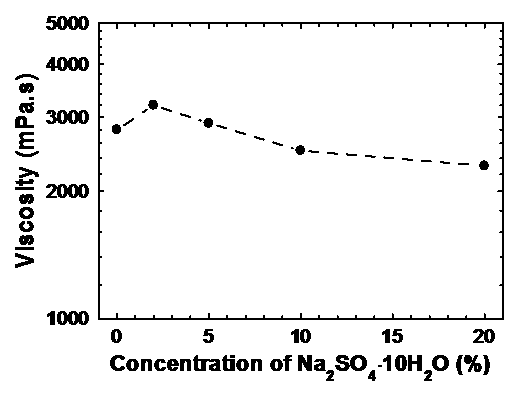

[0023] The salt tolerance performance measurement of embodiment 2 thickener

[0024] The salt-resistant ultra-high molecular weight thickener obtained in Example 1 is applied to sodium sulfate decahydrate (Na 2 SO 4 . 10H 2 O) 0-20% phase change material system. Weigh 1 gram of salt-resistant ultra-high molecular weight thickener, slowly add it to 100 ml of water, and stir at room temperature for 2 hours at a stirring speed of 1500 rpm, then seal it and put it in a water bath at 50°C Heat to swell for 2 hours, and finally cool to 25°C. The prepared solution was mixed at a shear rate of 1 s -1 Under the condition of , use Anton Paar MCR501 rotational rheometer to measure its viscosity value. Then, add 2%, 5%, 10% and 20% sodium sulfate decahydrate into the solution respectively, and continue to measure the corresponding viscosity value. figure 2 The measured solution viscosity varies with the salt concentration curve, the viscosity of the thickener is less affected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com