Preparation method of al2o3/tic coated cemented carbide based on liquid phase sintering process

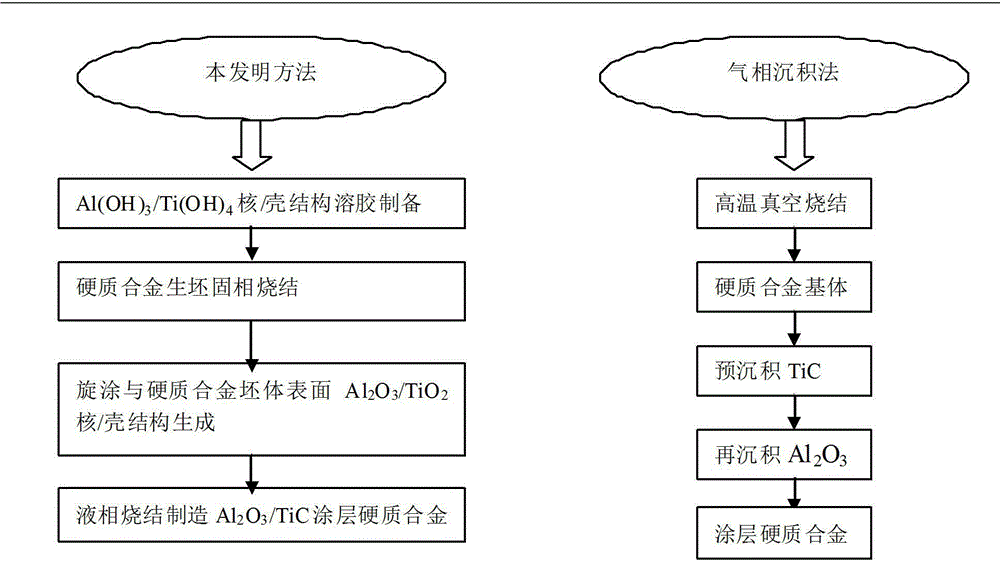

A cemented carbide, liquid phase sintering technology, applied in the coating, the device for coating liquid on the surface, the surface pretreatment, etc., can solve the problems of complex process and difficult control, and achieve simple process, easy control, and high efficiency. The effect of density and strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1: First Al(NO 3 ) 3 Prepare a solution with a volume percentage concentration of 0.8% with deionized water, add ammonia water to adjust the pH value of the solution to 8, stir at 25°C for 2 hours with a magnetic stirrer at a speed of 25 r / mi, and then place it for 8 hours to form Al(OH) 3 Sol; then add TiCl 4 , so that its volume percent concentration is 0.16%, which is equivalent to Al(NO 3 ) 3 20% of the concentration by volume, and add ammonia water to adjust the pH value to 8.2, stir at 50°C for 1h with a magnetic stirrer, and the speed of the magnetic stirrer is 25r / min, and then leave it for 10h to generate Ti(OH) 4 Coated Al(OH) 3 Al(OH) 3 / Ti(OH) 4 core / shell structure sol, Al(NO 3 ) 3 、TiCl 4 and ammonia were of analytical grade. Then weigh various raw material powder ingredients, according to the weight percentage, TiC accounts for 3%, TaC accounts for 2%, NbC accounts for 2%, Co accounts for 10%, and the rest is WC; Drying, mixing in the ...

example 2

[0020] Example 2: First Al(NO 3 ) 3 Prepare a solution with a volume percentage concentration of 3% with deionized water, add ammonia water to adjust the pH value of the solution to 9, stir at 50°C for 5 hours with a magnetic stirrer at a speed of 50 r / mi, and then place it for 10 hours to form Al(OH) 3 Sol; then add TiCl 4 , so that its volume percent concentration is 1.2%, which is equivalent to Al(NO 3 ) 3 40% of the concentration by volume, and add ammonia water to adjust the pH value to 8.4, stir at 70°C for 4 hours with a magnetic stirrer, the speed of the magnetic stirrer is 40r / min, and then place it for 11 hours to generate Ti(OH) 4 Coated Al(OH) 3 Al(OH) 3 / Ti(OH) 4 core / shell structure sol, Al(NO 3 ) 3 、TiCl 4 and ammonia were of analytical grade. Then weigh various raw material powder ingredients, TaC accounts for 3%, Co accounts for 8%, and the rest is WC; the mixed powder is ball milled for 48 hours, dried at 95°C with a 400-mesh screen, and mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com