Multi-mode discharging ignition system for gas engine

A gas engine and ignition system technology, applied in the direction of capacitor energy storage device, induction energy storage device, etc., can solve the problems of short discharge duration and poor ignition, and achieve the effect of high energy utilization rate and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

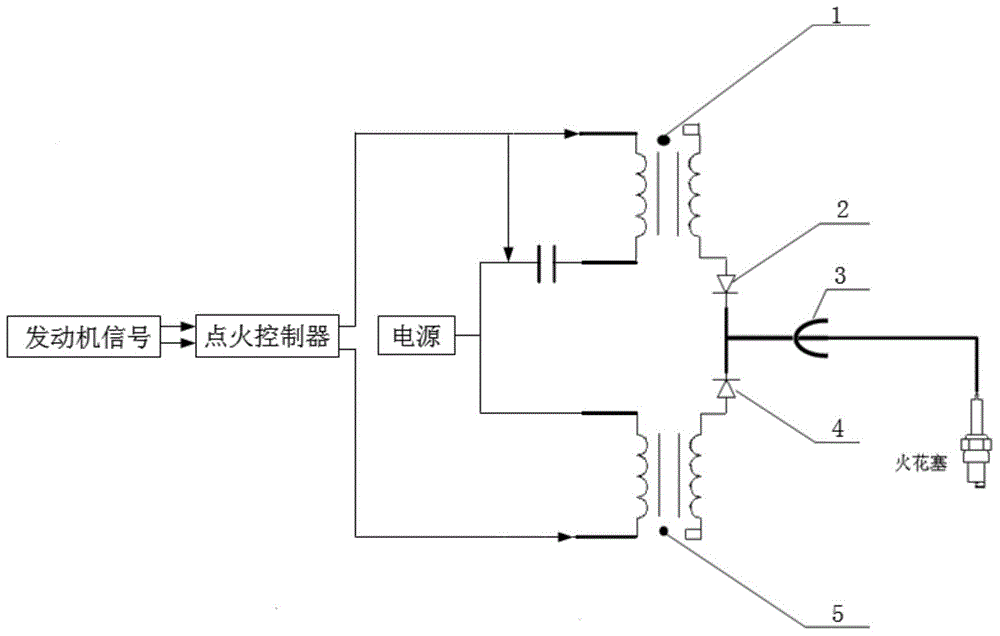

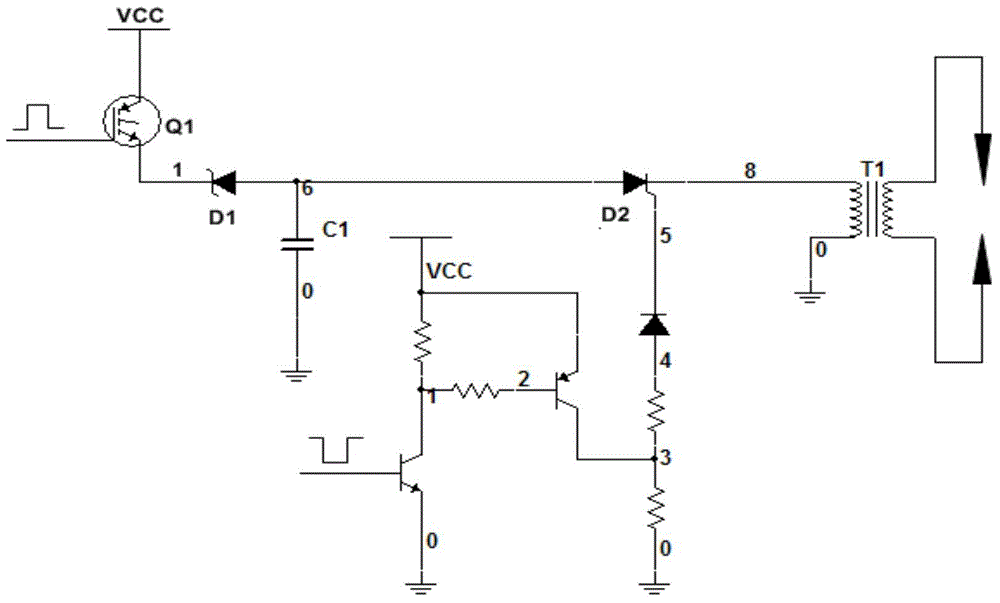

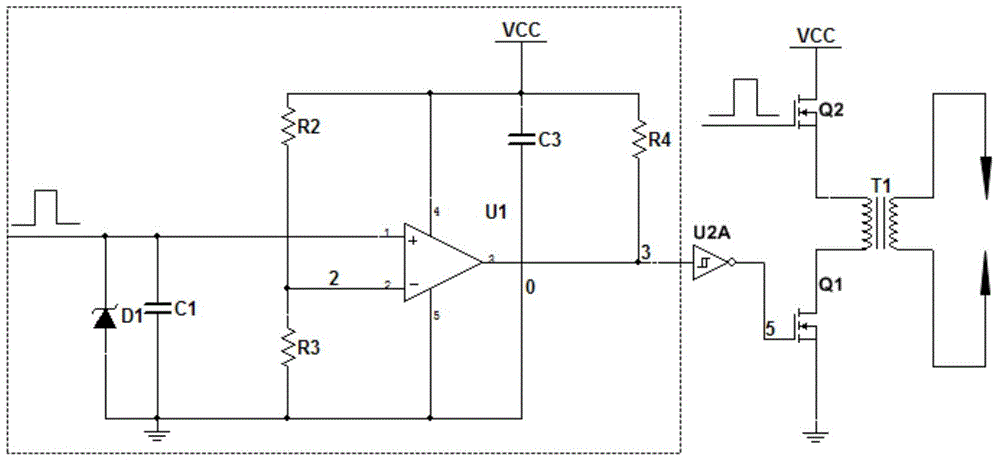

[0015] A multi-mode discharge ignition system for a gas engine, which includes: an ignition controller, a power supply, a capacitor energy storage type ignition coil, an inductance energy storage type ignition coil, an anti-reverse breakdown diode, an ignition high voltage line interface and a spark plug. The system includes an inductive energy storage ignition coil and a capacitive energy storage ignition coil. The two ignition coils can be controlled independently, and the discharge mode can be switched according to the working conditions of the natural gas engine. There is a signal conditioning circuit inside the ignition controller, which adjusts the top dead center signal and the speed signal into a standard square wave signal, and obtains the ignition control signal through the standard square wave signal, and the ignition control signal controls the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com