Method and device for generating high-precision optical fiber optical comb seed pulse through full-optical difference frequency

An optical difference frequency, high-precision technology, applied in the field of optics, can solve the problems that are difficult to achieve, the length of the optical fiber and the control precision of the pump light intensity are extremely high, and achieve the effect of eliminating secondary pulses, eliminating spontaneous radiation, and increasing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

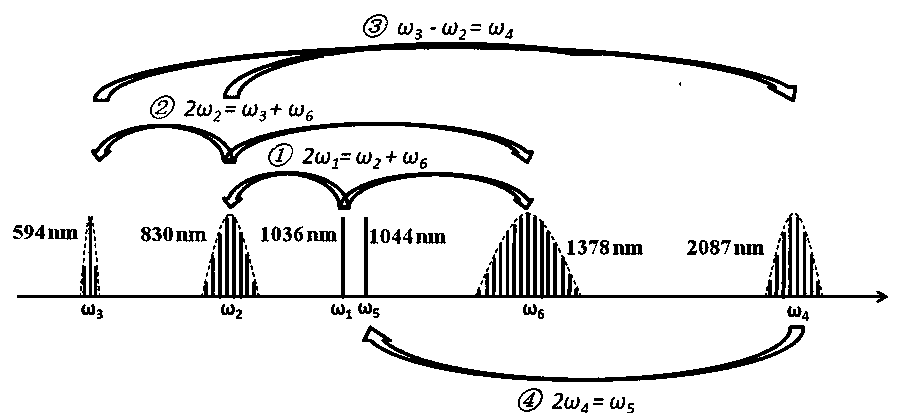

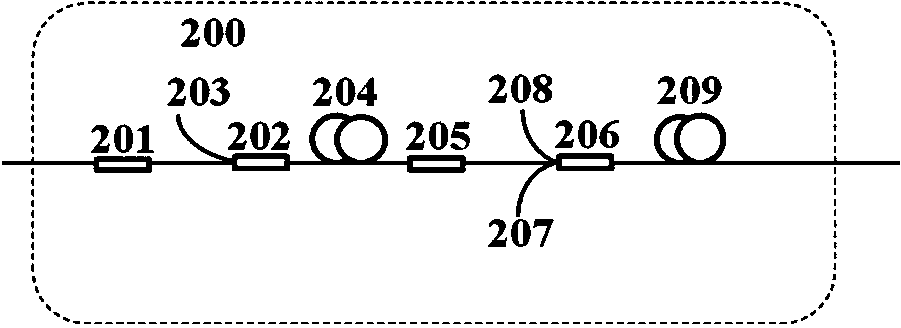

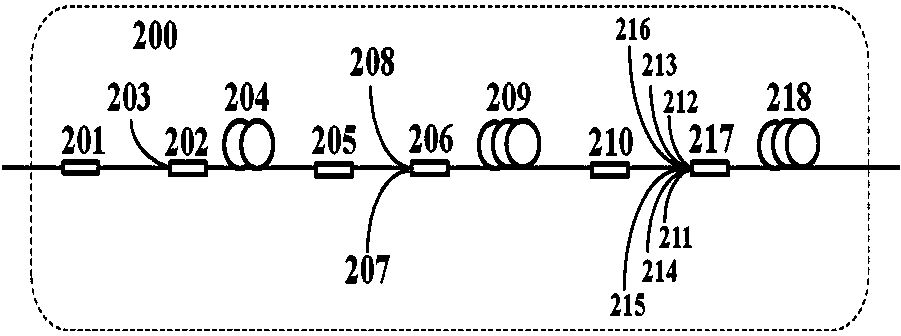

[0036] Refer to figure 2 The device of the present invention includes a laser oscillator 100, a six-wave mixer amplifier 200, an optical comb difference frequency converter 300, and an optical comb frequency multiplier 400.

[0037] The laser oscillator 100 is used to generate low-energy picosecond seed pulse signal light ω 1 , The pulse repetition frequency is on the order of kilohertz to hundred megahertz, and the center frequency is ω 1 =289.6THz, that is, the center wavelength is 1036nm, and the average power is several to tens of milliwatts. The output end of the laser oscillator 100 is connected to the six-wave mixer amplifier 200 through the input end of the optical isolator 201.

[0038] Refer to image 3 , The output end of the optical isolator 201 in the nonlinear six-wave mixing amplifier 200 formed by the two-stage cascaded fiber amplifier of the present invention is connected to an input end of the wavelength division multiplexer 202. The other input end of the wavele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com