Efficient controllable photooxidation-biodegradable plastic film and preparation method thereof

A plastic film and biodegradation technology, applied in the field of high-efficiency controllable photooxidation-biodegradable plastic film and its preparation, can solve the problems of uncontrollable degradation, incomplete degradation, complicated process, etc., and achieve the promotion of photocatalytic degradation and degradation efficiency The effect of improving and increasing the degree of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (2) The preparation method of each embodiment and comparative example plastic film is as follows:

[0040] According to the weighing principle of each embodiment or comparative example in Table 1, mix in a high-speed mixer and set aside. Extruder conditions: zone 1 100-120°C, zone 2 120-140°C, zone 3 140-160°C, zone 4 160-180°C, zone 5 165-185°C, head 165-185°C. After the temperature reaches a stable level, put the mixed raw materials into the feeding hopper, adjust the speed of the main machine and the feeder, melt and extrude the raw materials, pass through water, blow dry, cut into master batches, and then dry the master batches for use. Then set the temperature of the film blowing machine: the first zone is 100-110°C, the second zone is 125-135°C, the third zone is 145-155°C, and the die head is 145-155°C. After the temperature has stabilized, turn on the switch of the host machine, adjust the speed, add masterbatch, extrude and blown into a film, and the thickness...

Embodiment 6

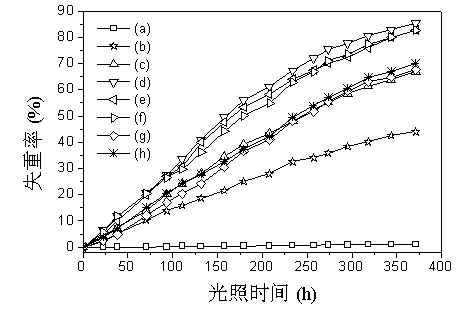

[0050] Embodiments 6-9 add different contents of nano-TiO 2 Efficient and controllable photooxidation-biodegradable plastic film, under light photooxidation-biodegradable plastic film all appeared induction period, embodiment 6 nanometer TiO 2 The content is the least, and the induction period is up to 250 hours, due to the nano-TiO 2 As the content increases, the degradation rate increases, and the corresponding induction period is shortened to 180 hours as in Example 9, the induction period does not disappear, and the degradation of the plastic film remains controllable. Degradation test results also showed that nano-TiO 2 When the content is low, increase TiO 2 content, the degradation effect is obvious, when it is greater than 3%, increase the TiO 2 content, the degradation effect is not obvious.

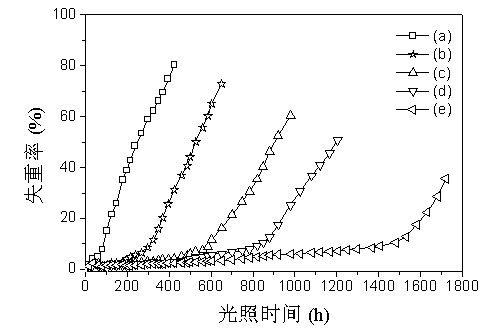

[0051] 4. Efficient and controllable photooxidation-biodegradable plastic films of Examples 10-13 with different types of hydrophilic modifiers added

[0052] Examples 10-1...

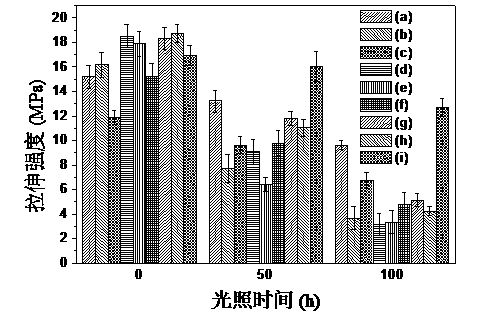

Embodiment 29~32

[0059] 8. Typical high-efficiency controllable photooxidation-biodegradable plastic films of Examples 29-32

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com