Application of carbonyl reductase ChKRED20 in catalyzing carbonyl substrate

A carbonyl compound and reductase technology, applied in the field of biocatalysis, can solve the problems of limited expansion range and narrow application range, and achieve the effect of high stereoselectivity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

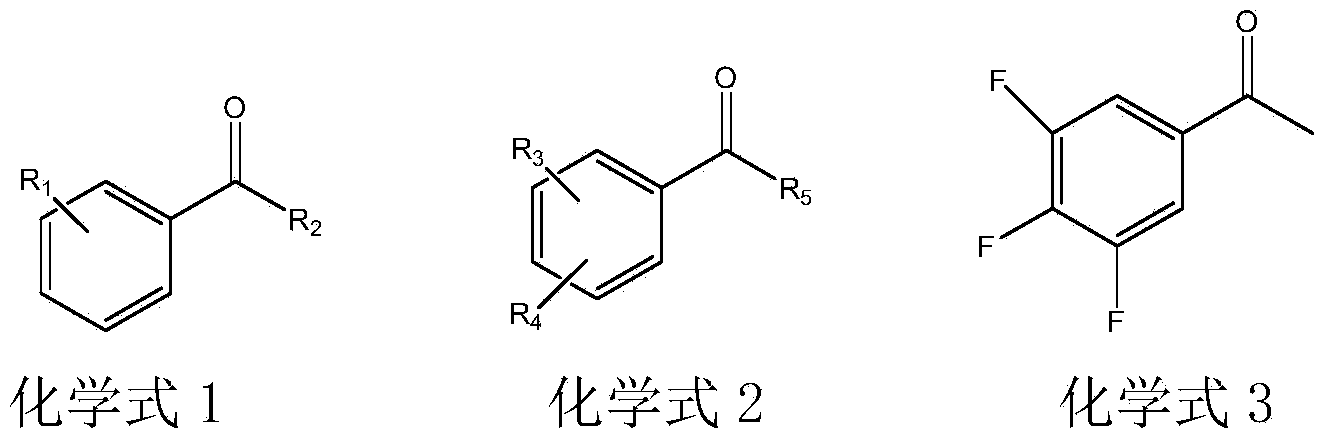

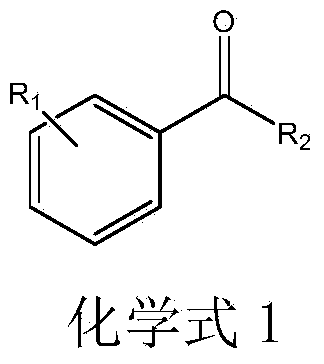

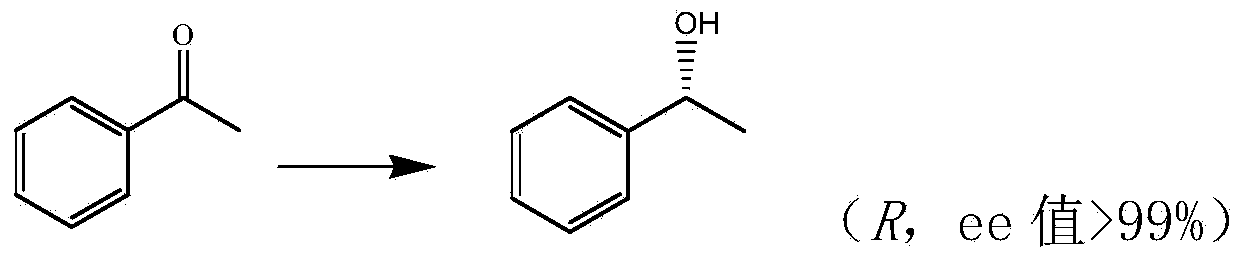

[0022] Example 1 Carbonyl Reductase ChKRED20 Reduction of Carbonyl Compounds Shown in Chemical Formula 1

[0023]

[0024] (1) R1 for H, R 2 for CH 3 :

[0025]

[0026] Carbonyl reductase ChKRED20 biocatalysis: reaction system 10ml, including potassium phosphate buffer (pH6.0, 0.1M), carbonyl reductase ChKRED20 pure enzyme 0.1mg / ml, NADH 20mM, substrate 10mM (prepared by dissolving in isopropanol) 10% mother liquor). Reaction conditions: 30°C, 150rpm, 24h.

[0027] After the reaction was finished, 10ml of ethyl acetate was used for extraction. The conversion and the ee value of the product were determined by chiral gas chromatography. Gas chromatography measurement conditions: Fuli Fuli GC9790 gas chromatograph, hydrogen ion flame FID detector, chiral column CP-Chirasil-DEX CB column (Varian, USA), inlet temperature 260 ° C, detector 280 ° C, column temperature 115°C, t R =9.3min,t S =10.1min. The conversion rate of the substrate was 83%, the product was in the...

Embodiment 2

[0050] Embodiment 2 Carbonyl reductase ChKRED20 catalyzes the carbonyl compound shown in chemical formula 2

[0051]

[0052] R 3 and R 4 Both are F, and respectively in the 3rd and 5th positions, R 5 for CH 3 :

[0053]

[0054] (a) Using the crude enzyme solution of carbonyl reductase ChKRED20 as a catalyst:

[0055] The reaction system and conditions are the same as in Example 1 (6), and the product treatment method is the same as in Example 1 (6). Gas chromatography measurement conditions: column temperature 90°C, other conditions are the same as in Example 1 (1). t R =46.2min,t S =50.5min. The conversion rate of the substrate was 100%, the product was in the R configuration, and the ee value was >99%. The product recovery yield was determined to be 93%.

[0056] (b) Using carbonyl reductase ChKRED20 recombinant bacterial dormant cells as a catalyst:

[0057] Biocatalytic system 10ml, including potassium phosphate buffer (pH7.0, 0.1M), carbonyl reductase C...

Embodiment 3

[0059] Embodiment 3 carbonyl reductase ChKRED20 catalyzes the carbonyl compound shown in chemical formula 3

[0060]

[0061] Using carbonyl reductase ChKRED20 lyophilized crude enzyme powder as catalyst:

[0062] Biocatalytic system 10ml, including potassium phosphate buffer (pH8.0, 0.1M), carbonyl reductase ChKRED20 crude enzyme powder 10g / l, isopropanol 40% (v / v), NAD + 0.2g / l, substrate 20mM (dissolved in isopropanol to make 30% mother solution). Reaction conditions: 30°C, 120rpm, 10h. The product treatment method is the same as in Example 1 (1). Gas chromatography measurement conditions: column temperature 100°C, other conditions are the same as in Example 1 (1). t R =30.1min,t S =32.2min. The conversion rate of the substrate was 100%, the product was in the R configuration, and the ee value was >99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com