Preparation method of nanotube array positive electrode material of lithium sulphur battery

A technology of nanotube arrays and positive electrode materials, applied in battery electrodes, electrolytic organic material coatings, electrolytic inorganic material coatings, etc., can solve the problems of low specific capacity and poor conductivity, and achieve increased sulfur loading, improved conductivity, Coulombic The effect of stable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

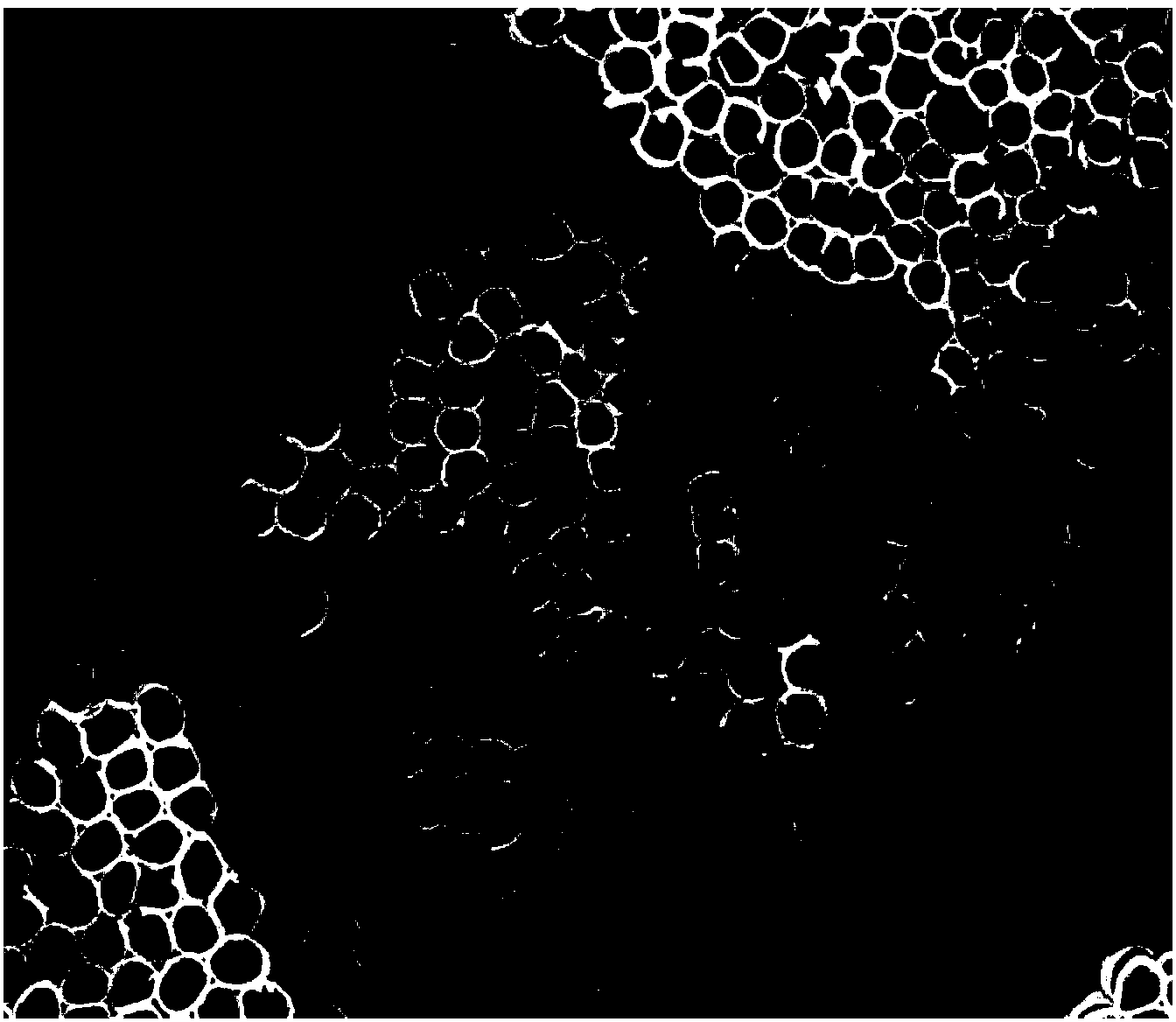

[0054] Embodiment 1, including the step of preparing a titanium dioxide nanotube array, the step of depositing a conductive enhancing material and the step of depositing elemental sulfur:

[0055] (1) The step of preparing titanium dioxide nanotube arrays includes the following sub-steps:

[0056] (1.1) Titanium sheet treatment: Polish both sides of the titanium sheet with a purity of 99.8%, then ultrasonically clean it with acetone, distilled water, and absolute ethanol in order to remove surface oil, and finally wash it with N 2 blow dry;

[0057] (1.2) Preparation of electrolyte: mix NH 4 F Add mixed solvent, stir magnetically, make NH 4 F is completely dissolved in the mixed solvent to form an electrolyte; the mixed solvent is a mixed solution of distilled water and ethylene glycol, and the volume percentage of distilled water in the mixed solution is 2vol%; the NH 4 The mass percentage of F accounting for the electrolyte is 0.25Wt%;

[0058] (1.3) The first step of ox...

Embodiment 2

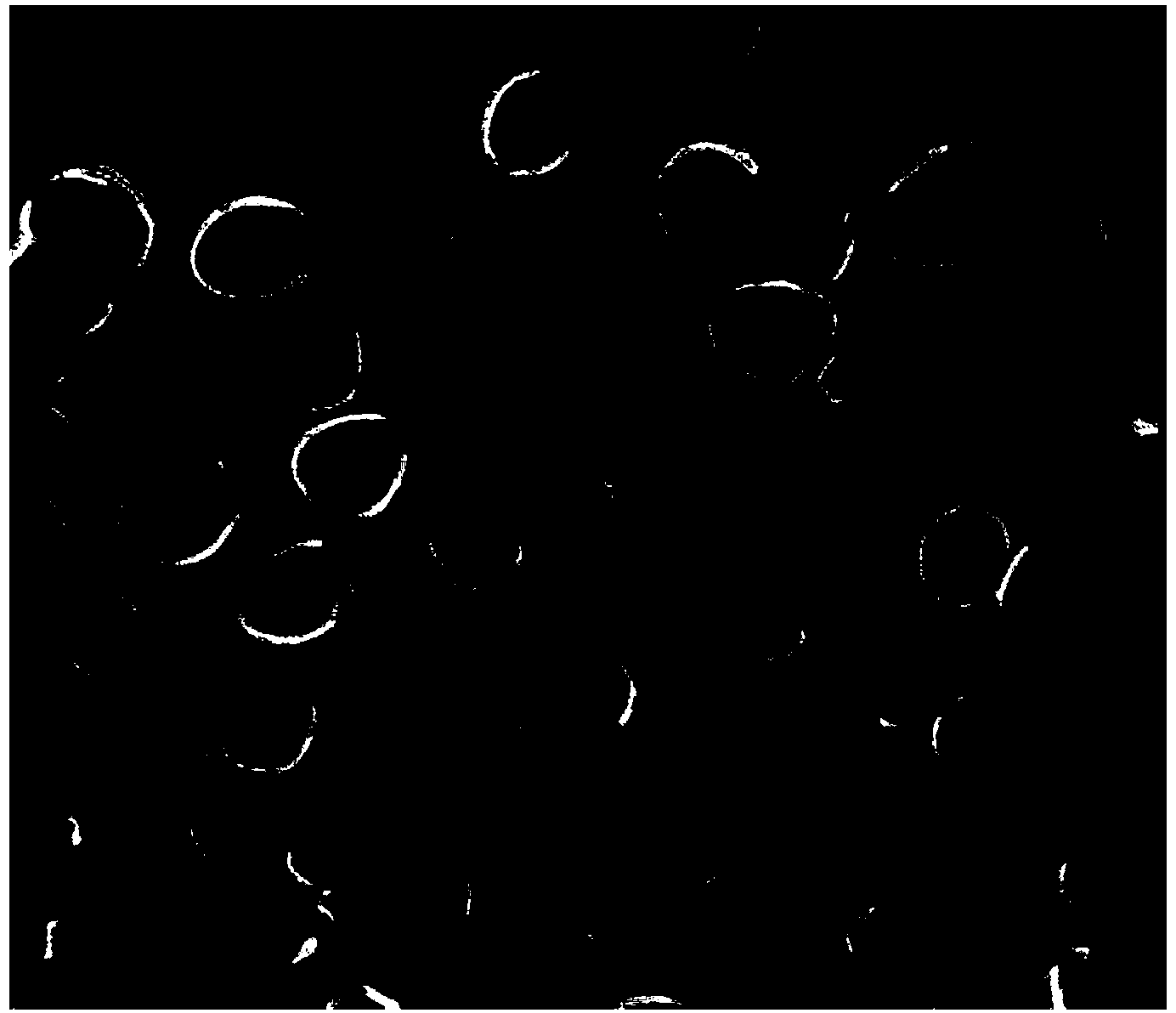

[0070] Embodiment 2, including the step of preparing a titanium dioxide nanotube array, the step of depositing a conductive enhancing material and the step of depositing elemental sulfur:

[0071] (1) The step of preparing titanium dioxide nanotube arrays includes the following sub-steps:

[0072] (1.1) Titanium sheet treatment: Polish both sides of the titanium sheet with a purity of 99.8%, then ultrasonically clean it with acetone, distilled water, and absolute ethanol in order to remove surface oil, and finally wash it with N 2 blow dry;

[0073] (1.2) Preparation of electrolyte: mix NH 4 F Add mixed solvent, stir magnetically, make NH 4 F is completely dissolved in the mixed solvent to form an electrolyte; the mixed solvent is a mixed solution of distilled water and ethylene glycol, and the volume percentage of distilled water in the mixed solution is 2vol%; the NH 4 The mass percentage of F accounting for the electrolyte is 0.25Wt%;

[0074] (1.3) The first step of ox...

Embodiment 3

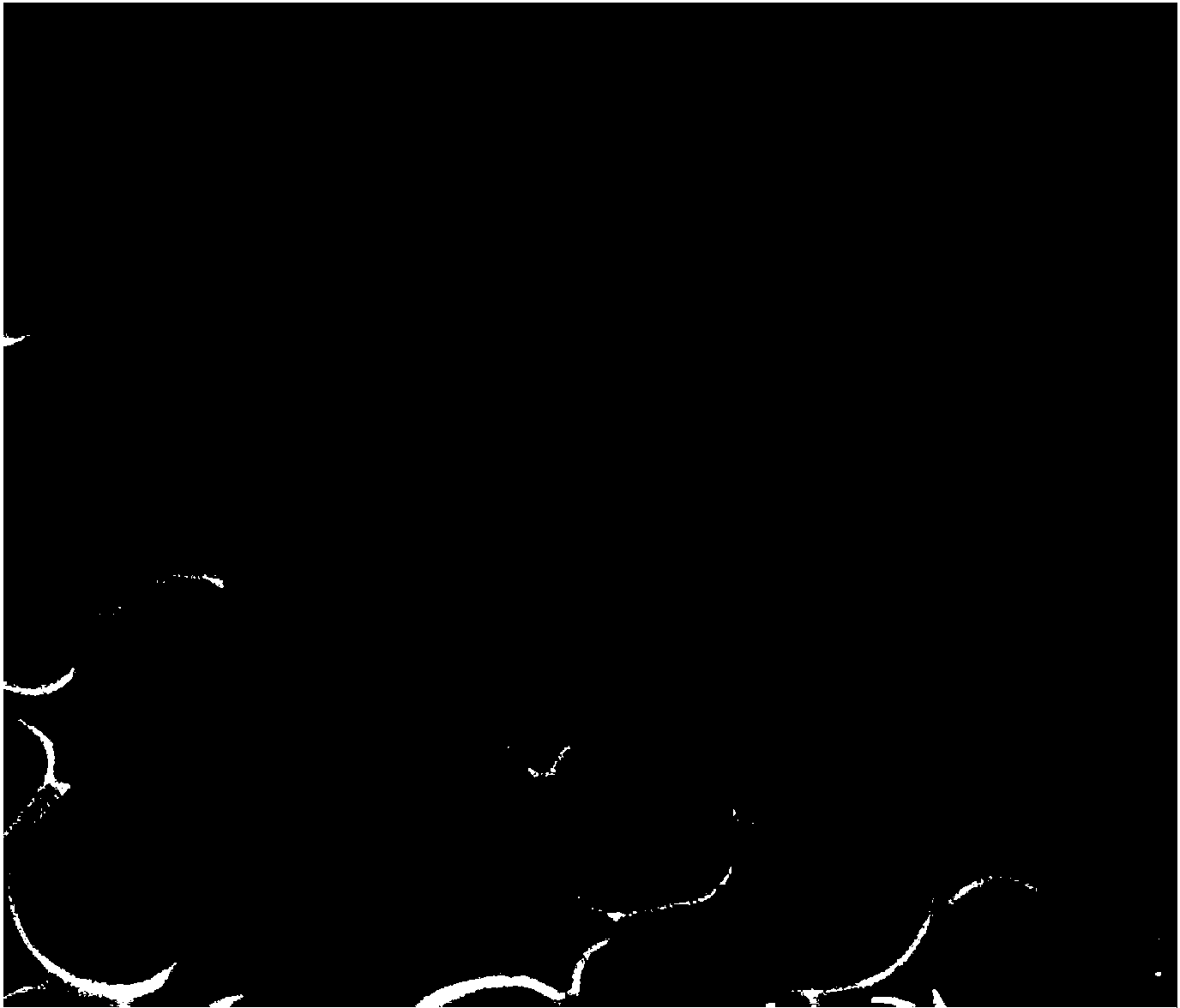

[0086] Embodiment 3, including the step of preparing a titanium dioxide nanotube array, the step of depositing a conductive enhancing material and the step of depositing elemental sulfur:

[0087] (1) The step of preparing titanium dioxide nanotube arrays includes the following sub-steps:

[0088] (1.1) Titanium sheet treatment: Polish both sides of the titanium sheet with a purity of 99.8%, then ultrasonically clean it with acetone, distilled water, and absolute ethanol in order to remove surface oil, and finally wash it with N 2 blow dry;

[0089] (1.2) Preparation of electrolyte: mix NH 4 F Add mixed solvent, stir magnetically, make NH 4 F is completely dissolved in the mixed solvent to form an electrolyte; the mixed solvent is a mixed solution of distilled water and ethylene glycol, and the volume percentage of distilled water in the mixed solution is 2vol%; the NH 4 The mass percentage of F accounting for the electrolyte is 0.25Wt%;

[0090] (1.3) The first step of ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com