Formic acid fuel cell anode catalytic material

A formic acid fuel cell and catalytic material technology, applied in battery electrodes, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of changing the catalytic performance of Pd electrocatalysts, reducing the activity of palladium catalysts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

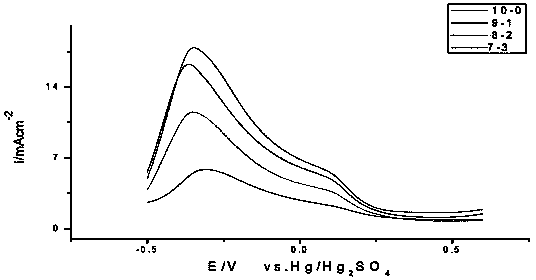

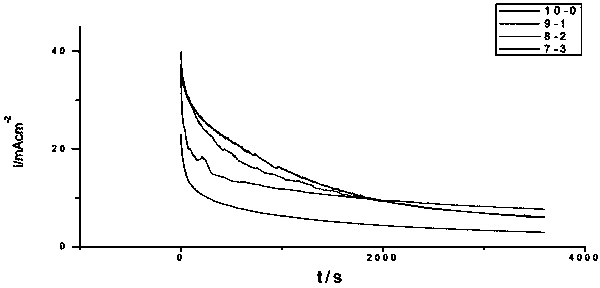

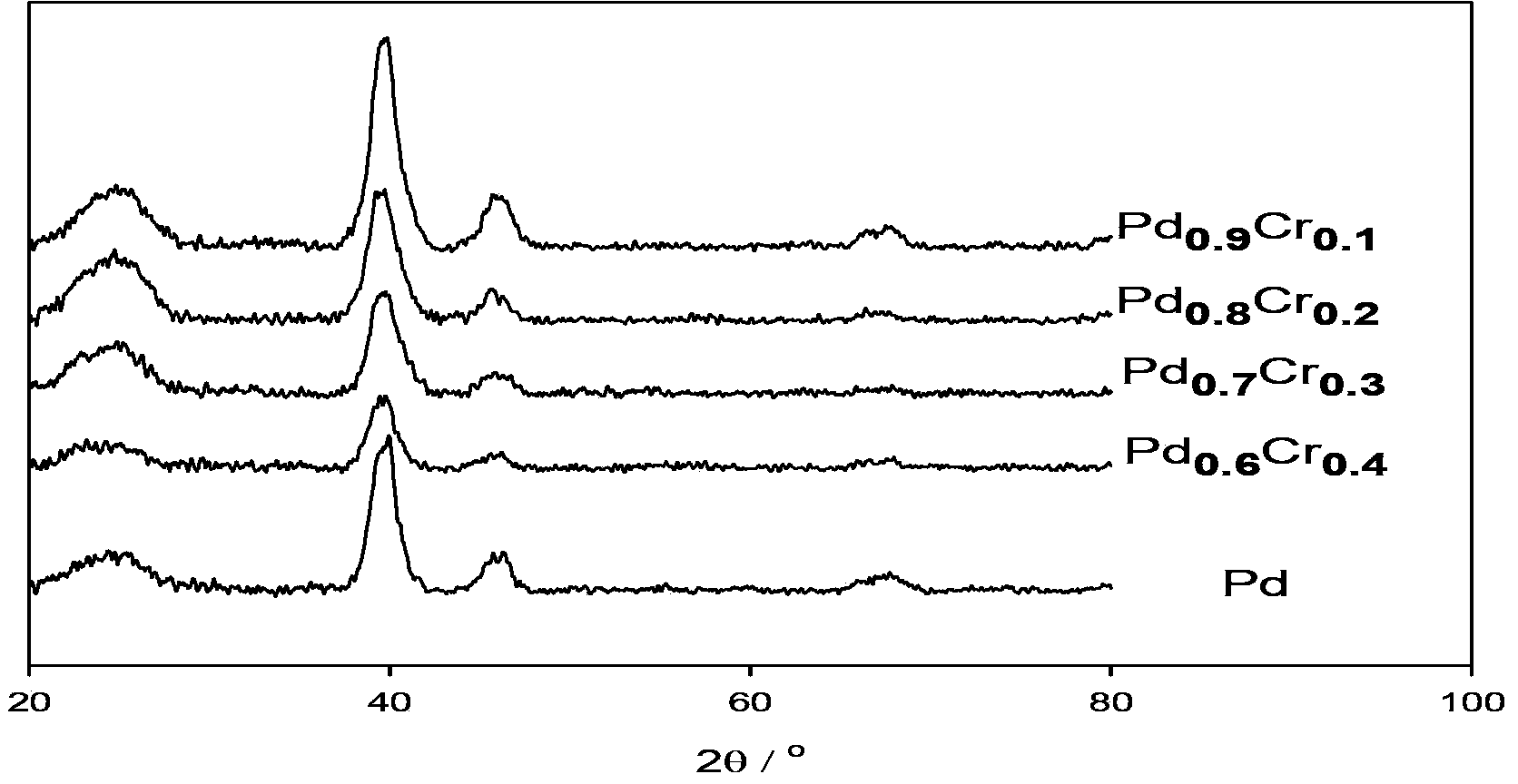

Embodiment 1

[0013] Use a beaker to weigh 8 mg of activated carbon on an electronic balance, add 6.7 mL of distilled water, and then add 0.5 mL of absolute ethanol to reduce surface tension and prevent carbon powder from floating, and add palladium salt and chromium according to the palladium-chromium molar ratio of 7:3 Saline solution, then ultrasonically oscillate for more than 30 minutes, then add 10 μL of 0.2mol / L NaOH solution, adjust its pH value to about 10, and then add about 2mL of 5% NaBH 4 The solution was then stirred continuously for 15 minutes and left to stand overnight to obtain the precipitation of carbon-supported palladium-chromium alloy material (Pd-Cr / C). Filter the liquid containing Pd-Cr / C precipitate, wash the Pd-Cr / C precipitate several times with twice distilled water, and use AgNO 3 Check until the washing solution does not contain Cl- ions, then transfer the Pd-Cr / C material into a beaker and heat it on a hot plate. After it is slightly dry, transfer it to a vac...

Embodiment 2

[0015] Use a beaker to weigh 8 mg of activated carbon on an electronic balance, add 6.7 mL of distilled water, and then add 0.5 mL of absolute ethanol to reduce surface tension and prevent carbon powder from floating. Add palladium salt and chromium according to the molar ratio of palladium to chromium is 8:2 Saline solution, then ultrasonically oscillate for more than 30 minutes, then add 10 μL of 0.2mol / L NaOH solution, adjust its pH value to about 10, and then add about 2mL of 5% NaBH 4 The solution was then stirred continuously for 15 minutes and left to stand overnight to obtain the precipitation of carbon-supported palladium-chromium alloy material (Pd-Cr / C). Filter the liquid containing Pd-Cr / C precipitate, wash the Pd-Cr / C precipitate several times with twice distilled water, and use AgNO 3 Check until the washing solution does not contain Cl- ions, then transfer the Pd-Cr / C material into a beaker and heat it on a hot plate. After it is slightly dry, transfer it to a v...

Embodiment 3

[0017] Use a beaker to weigh 8 mg of activated carbon on an electronic balance, add 6.7 mL of distilled water, and then add 0.5 mL of absolute ethanol to reduce surface tension and prevent carbon powder from floating. Add palladium salt and chromium according to the molar ratio of palladium to chromium is 9:1 Saline solution, then ultrasonically oscillate for more than 30 minutes, then add 10 μL of 0.2mol / L NaOH solution, adjust its pH value to about 10, and then add about 2mL of 5% NaBH 4 The solution was then stirred continuously for 15 minutes and left to stand overnight to obtain the precipitation of carbon-supported palladium-chromium alloy material (Pd-Cr / C). Filter the liquid containing Pd-Cr / C precipitate, wash the Pd-Cr / C precipitate several times with twice distilled water, and use AgNO 3 Check until the wash solution is free of Cl - ions, and then transfer the Pd-Cr / C material into a beaker and heat it on a hot plate. , that is, get Pd 0.9 Cr 0.1 / C alloy cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sub diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com