Ball-milling classification production equipment for high-purity quartz powder

A technology of high-purity quartz powder and production equipment, which is applied in the direction of solid separation, separation of solids from solids with air flow, grain processing, etc., and can solve problems such as difficulty in adapting to market demand, high energy consumption of jet mills, and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

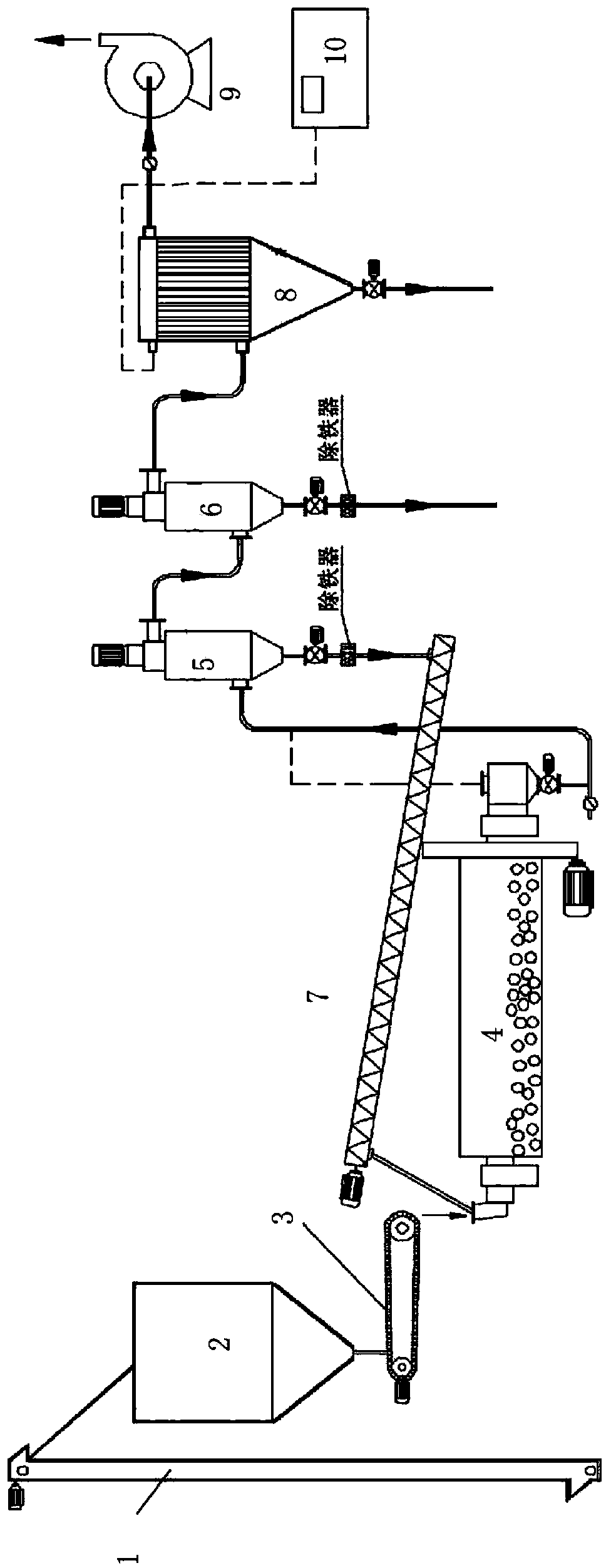

[0012] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a high-purity quartz powder ball mill classification production equipment according to the present invention will be given below in conjunction with the drawings and preferred embodiments. , Structure, characteristics and effects are described in detail later.

[0013] See figure 1 Shown is the structure diagram of the ball mill and classification production equipment of high purity quartz powder of the present invention.

[0014] The ball mill classification production equipment of this high-purity quartz powder mainly includes elevator 1, silo 2, belt feeder 3, ball mill 4, classifier Ⅰ5, classifier Ⅱ6, return screw 7, dust collector 8, and induced draft fan 9. And air compressor 10.

[0015] The hoist 1 is connected to the inlet of the silo 2; the outlet of the silo 2 is connected to the belt feeder 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com