Production method and equipment for conversion of human faeces into fertilizer and fertilizer produced thereby

A production method and excrement technology, applied in the directions of organic fertilizers, excretion fertilizers, waste fuels, etc., can solve problems such as difficulty in finding burials, waste of resources, pollution of the environment, etc., so as to improve energy utilization, reduce pollution, and reduce odor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

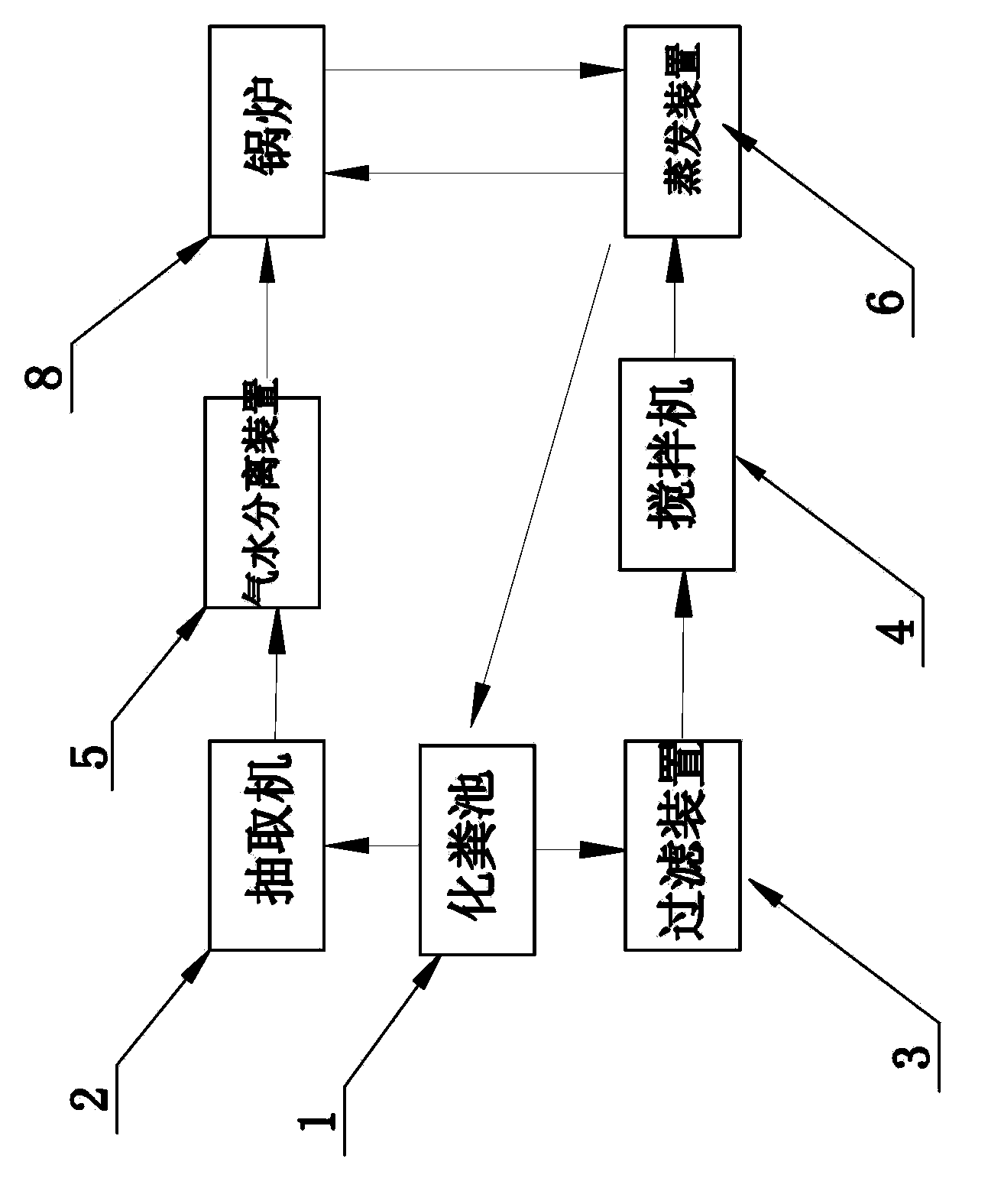

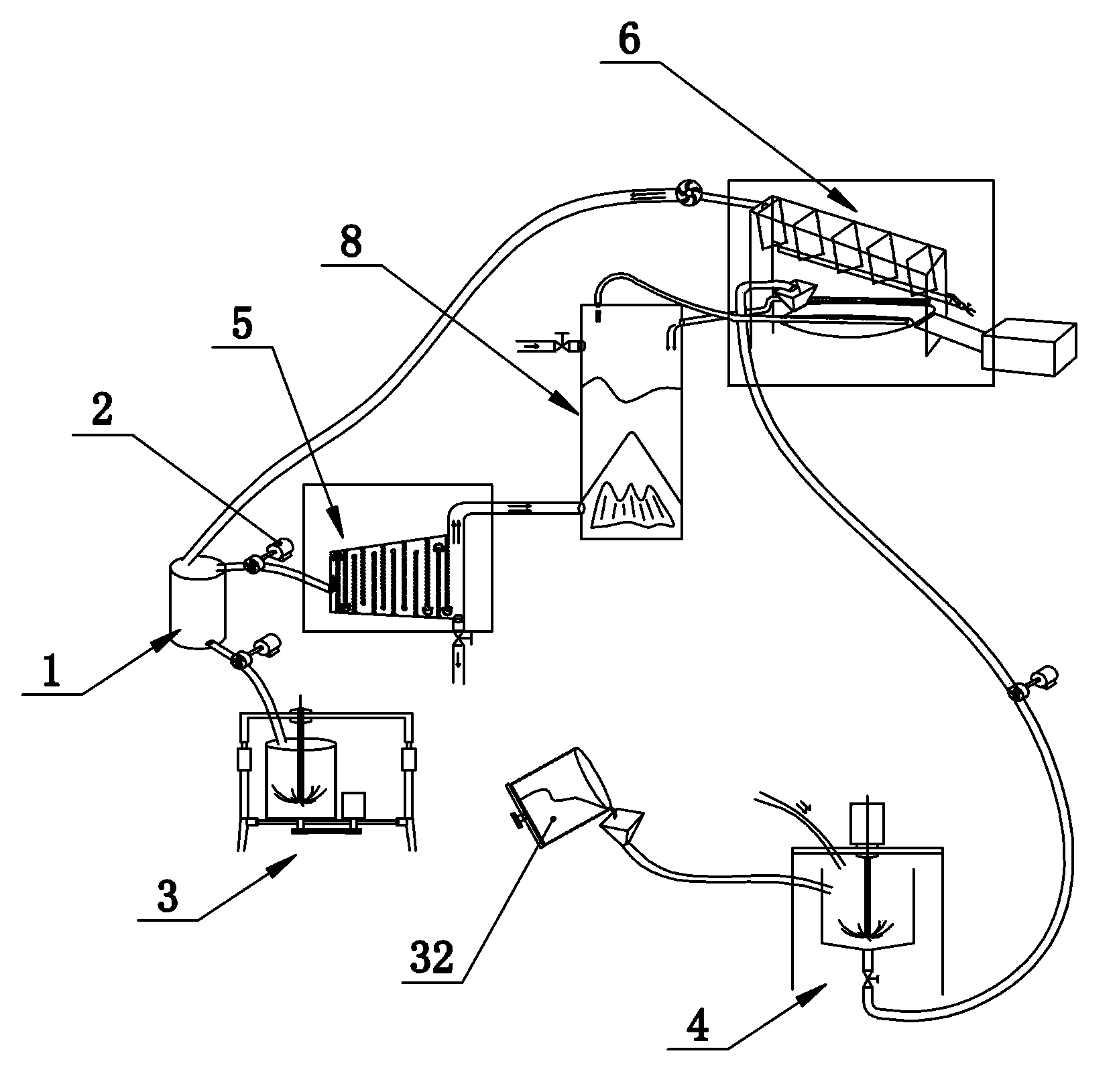

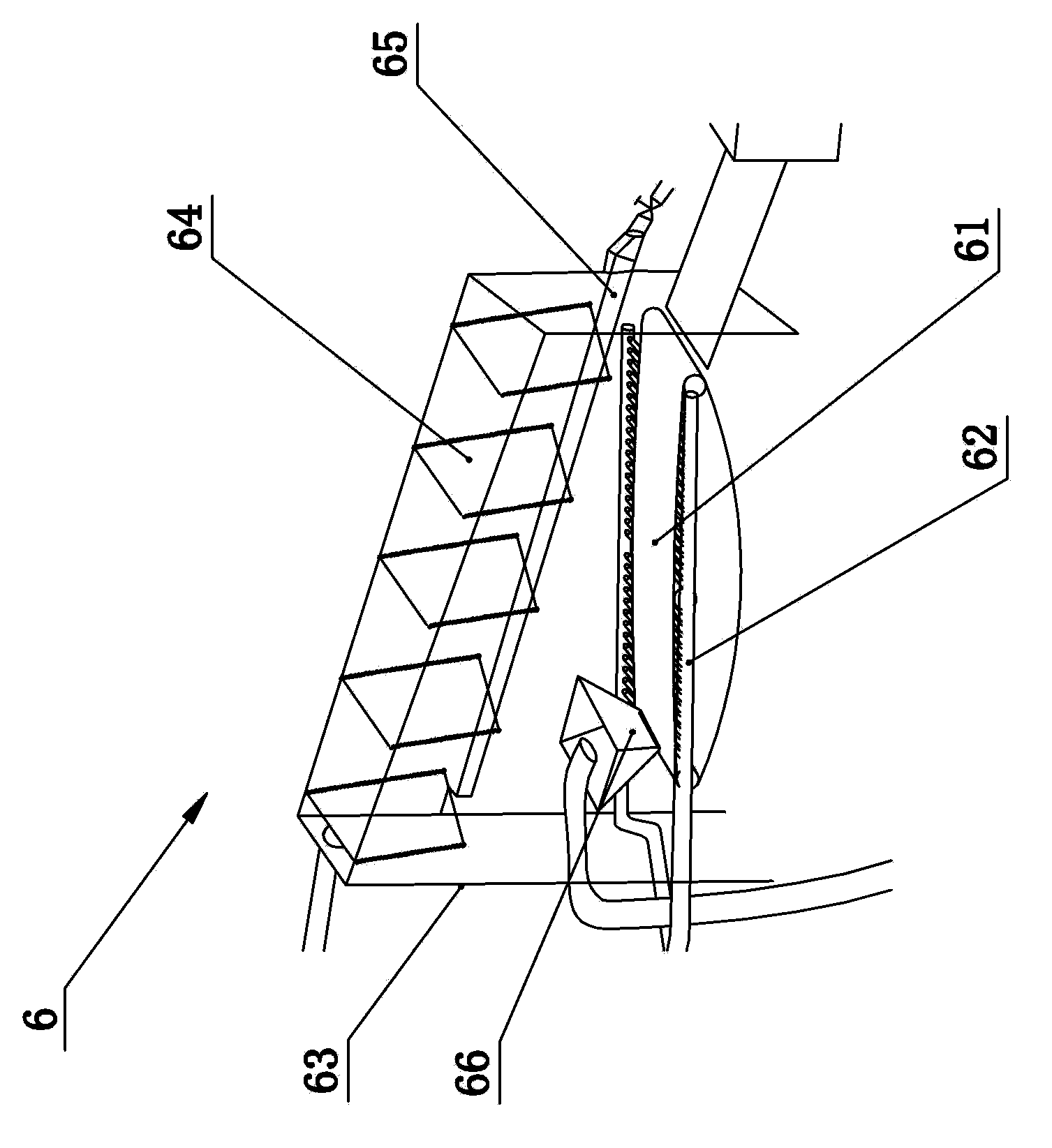

[0027] See attached figure 1 to attach Figure 5 , the production method of converting human excrement into fertilizer disclosed by the present invention comprises the following steps: 1. Extracting the biogas in the septic tank 1 through the extraction machine 2, and using the solid and liquid feces in the septic tank as the original slurry; Two, the original slurry of step 1 is filtered through filter device 3, removes sundry, obtains preliminary fecal slurry; 3, adds mud powder and fine sand to the preliminary fecal slurry obtained in step 2 and stirs and mixes in mixer 4 , to obtain semi-dry slag of feces; 4. Dry the biogas extracted in step 1 through the gas-water separation device 5; Heating and evaporation are carried out in the device 6 to obtain feces dry residue, and the evaporated gas of the semi-dry residue of feces is returned to the septic tank. The biogas obtained in step 1 can be used in step 4, which improves the utilization rate of resources and reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com