Method for applying esterification tail gas produced in synthesis of butyl isocyanate to salification

A technology of n-butyl isocyanate and butyl isocyanate, which is applied in the application field of esterification tail gas in the synthesis of n-butyl isocyanate in the application field of salt formation, can solve the problems of large material loss, high equipment investment, and large pollution, and achieve less waste acid , less investment in equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

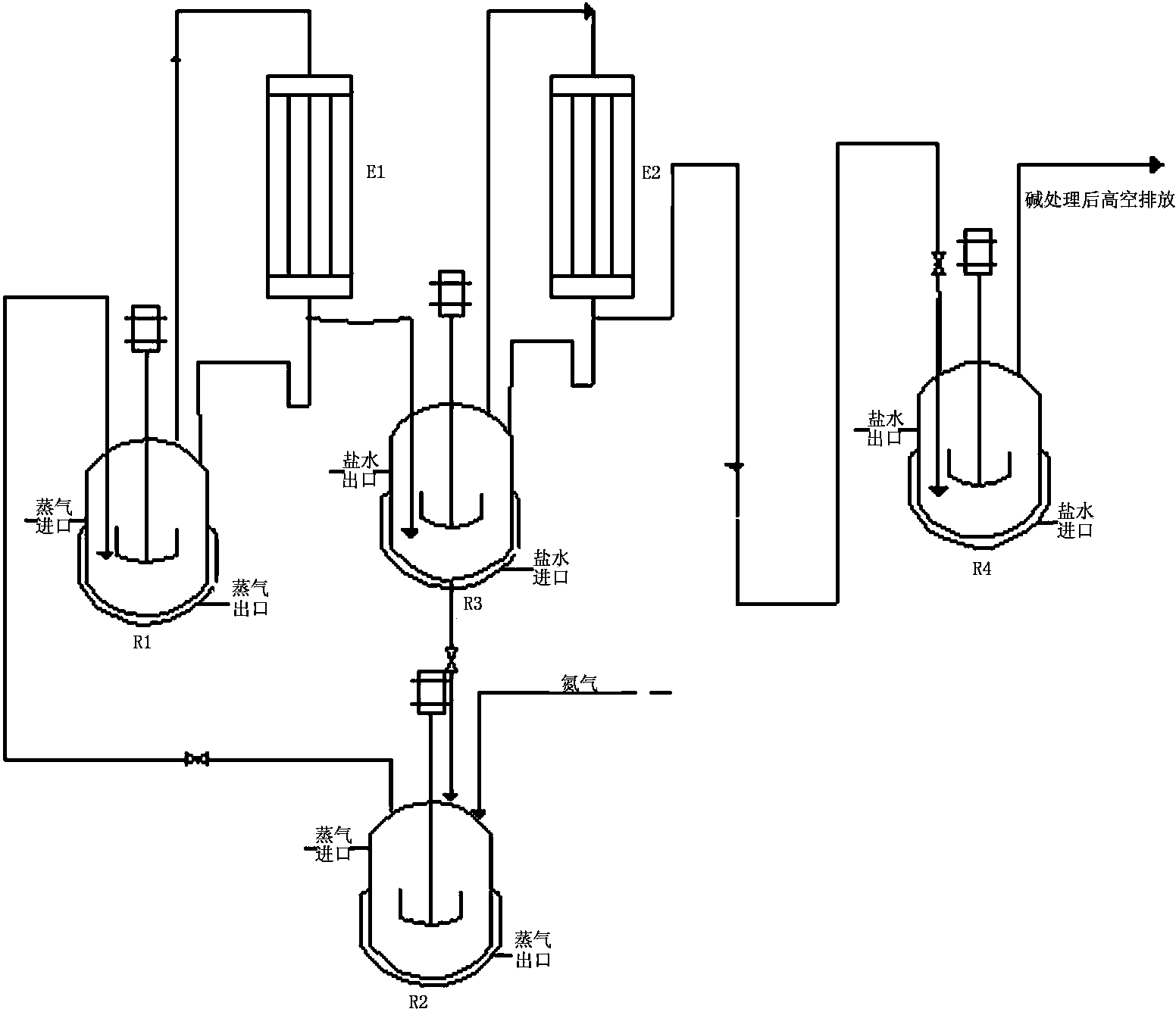

[0021] Collect the tail gas from the esterification reaction of preparing n-butyl isocyanate into the tail gas buffer tank, and then pass the tail gas into the xylene absorption tank at -5 ° C ~ 0 ° C for bubbling absorption, and the gas after absorbing phosgene in the absorption tank is condensed by the condenser, without The condensed hydrogen chloride gas is pressed into the storage tank for the salt-forming reaction of n-butylamine. When the mass concentration of phosgene in the solvent xylene reaches 50% to 60%, switch to another tank for absorption.

[0022] Turn on the cooling water in the jacket of the salt-forming kettle, and then start stirring, add 300L (264 Kg) of xylene and 73.21Kg of n-butylamine to the salt-forming kettle in sequence (the molar ratio of n-butylamine to xylene is 1:2.5), and wait until When the temperature of the salt kettle is 25°C-30°C, feed the hydrogen chloride tail gas of the esterification reaction of n-butyl isocyanate after separati...

Embodiment 2

[0024] Collect the tail gas from the esterification reaction of preparing n-butyl isocyanate into the tail gas buffer tank, and then pass the tail gas into the xylene absorption tank at -5 ° C ~ 0 ° C for bubbling absorption, and the gas after absorbing phosgene in the absorption tank is condensed by the condenser, without The condensed hydrogen chloride gas is pressed into the storage tank for the salt-forming reaction of n-butylamine. When the mass concentration of phosgene in the solvent xylene reaches 50% to 60%, switch to another tank for absorption.

[0025] Turn on the cooling water in the jacket of the salt-forming kettle, and then start stirring, add 300L (264 Kg) of xylene and 73.21Kg of n-butylamine to the salt-forming kettle in sequence (the molar ratio of n-butylamine to xylene is 1:2.5), and wait until When the temperature of the salt kettle is 25°C-30°C, feed the hydrogen chloride tail gas of the esterification reaction of n-butyl isocyanate after separati...

Embodiment 3

[0027] Collect the tail gas from the esterification reaction of preparing n-butyl isocyanate into the tail gas buffer tank, and then pass the tail gas into the xylene absorption tank at -5 ° C ~ 0 ° C for bubbling absorption, and the gas after absorbing phosgene in the absorption tank is condensed by the condenser, without The condensed hydrogen chloride gas is pressed into the storage tank for the salt-forming reaction of n-butylamine. When the mass concentration of phosgene in the solvent xylene reaches 50% to 60%, switch to another tank for absorption.

[0028] Turn on the cooling water in the jacket of the salt-forming kettle, and then start stirring, add 300L (264 Kg) of xylene and 73.21Kg of n-butylamine to the salt-forming kettle in sequence (the molar ratio of n-butylamine to xylene is 1:2.5), and wait until When the temperature of the salt kettle is 25°C-30°C, feed the hydrogen chloride tail gas of the esterification reaction of n-butyl isocyanate after separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com