Mode interference annular cavity optical fiber laser sensor

A fiber laser and mode interference technology, which is applied in the field of optoelectronics, can solve the problems that mode interference fiber sensors cannot be applied, and fiber grating laser sensors are cross-sensitive to temperature and strain. effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

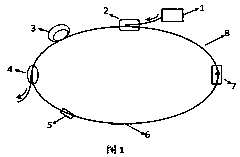

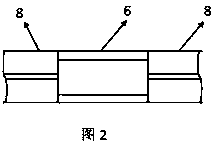

[0015] In order to further illustrate the technical characteristics of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, figure 1 Schematic diagram of the structure of the mode interference ring cavity fiber laser sensor. The device of the present invention includes: pump source 1, wavelength division multiplexer 2, rare earth doped active fiber 3, output coupler 4, polarization controller 5, multimode fiber 6, fiber isolator 7, single-mode transmission Fiber 8. The optical fiber fusion technology is used to connect the output ends of each part of the optical fiber, and the multimode optical fiber part is packaged as a sensing probe to form a mode interference ring cavity optical fiber laser sensor.

[0016] 1) The pump source 1 adopts a single-mode fiber-coupled semiconductor laser with an operating wavelength of 980nm / 1480nm. The output fiber of the pump source 1 is fused wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com