Method for manufacturing solid electrolytic capacitor suitable for high nominal voltage higher than 75V

A technology of rated voltage and solid electrolysis, which is applied in the direction of solid electrolytic capacitors, capacitor electrodes, capacitor parts, etc., can solve the problem of low capacity extraction rate of electrolytic capacitors, achieve omission of cleaning links, improve stability and reliability, and simplify production The effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

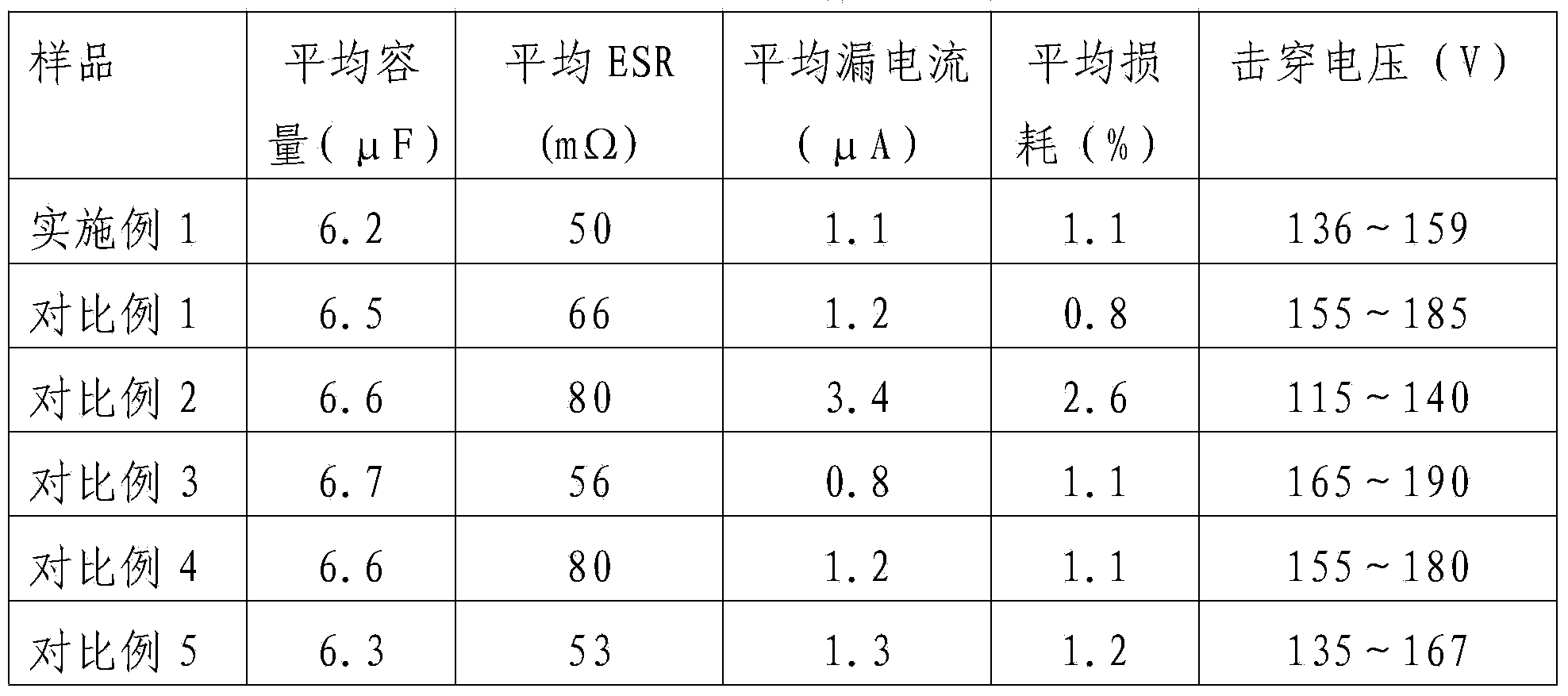

Examples

Embodiment 1

[0036] A method for manufacturing a solid electrolytic capacitor with a high rated voltage above 75V, comprising the following steps:

[0037] (1) Place the sintered capacitor anode body in a phosphoric acid solution with a concentration of 0.03%, firstly through a cross-flow boost, and then through an electrochemical reaction process of constant voltage drop-off, an amorphous dielectric oxidation is formed on the surface of the anode body membrane;

[0038] (2) Pretreatment: immerse the anode body with the dielectric layer formed in the diluent of silane coupling agent, and dry and cure in an environment of 200°C until a surface precoat is formed on the surface of the dielectric layer of the anode body;

[0039] (3) The first layer of conductive polymer film is obtained by impregnating a low-viscosity conductive polymer dispersion in a negative pressure-positive pressure environment, including:

[0040] A1, the anode body covered with surface pre-coating in 10 -2 Immerse in...

Embodiment 2

[0051] A method for manufacturing a solid electrolytic capacitor with a high rated voltage above 75V, comprising the following steps:

[0052] (1) Place the sintered capacitor anode body in a phosphoric acid solution with a concentration of 20%, firstly through a cross-flow boost, and then through an electrochemical reaction process of constant voltage drop-off, an amorphous dielectric oxidation is formed on the surface of the anode body membrane;

[0053] (2) Pretreatment: immerse the anode body with the dielectric layer formed in the silane coupling agent diluent, and dry and cure in an environment of 100°C until a surface precoat is formed on the surface of the dielectric layer of the anode body;

[0054] (3) The first layer of conductive polymer film is obtained by impregnating a low-viscosity conductive polymer dispersion in a negative pressure-positive pressure environment, including:

[0055] A1, the anode body covered with surface pre-coating in 10 -1 Immerse in a 50...

Embodiment 3

[0066] A method for manufacturing a solid electrolytic capacitor with a high rated voltage above 75V, comprising the following steps:

[0067] (1) Place the sintered capacitor anode body in a p-toluenesulfonic acid solution with a concentration of 10%. First, it undergoes a cross-flow boost, and then undergoes an electrochemical reaction process of constant voltage drop-off to form an amorphous state on the surface of the anode body. Dielectric oxide film;

[0068] (2) Pretreatment: immerse the anode body with the dielectric layer formed in the diluent of silane coupling agent, and dry and cure in an environment of 300°C until a surface precoat is formed on the surface of the dielectric layer of the anode body;

[0069] (3) The first layer of conductive polymer film is obtained by impregnating a low-viscosity conductive polymer dispersion in a negative pressure-positive pressure environment, including:

[0070] A1, the anode body covered with surface pre-coating in 10 -5 Imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com