Organic electroluminescence device and preparation method thereof

An electroluminescence device and an electroluminescence technology, which are applied in the field of electric light sources, can solve the problems of unsatisfactory luminous efficiency of the light-emitting device, low carrier transport efficiency, uneven doping of the transport layer, etc., and achieve the hole transport layer by layer. The structure is uniform and stable, the effect of improving hole transport efficiency and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

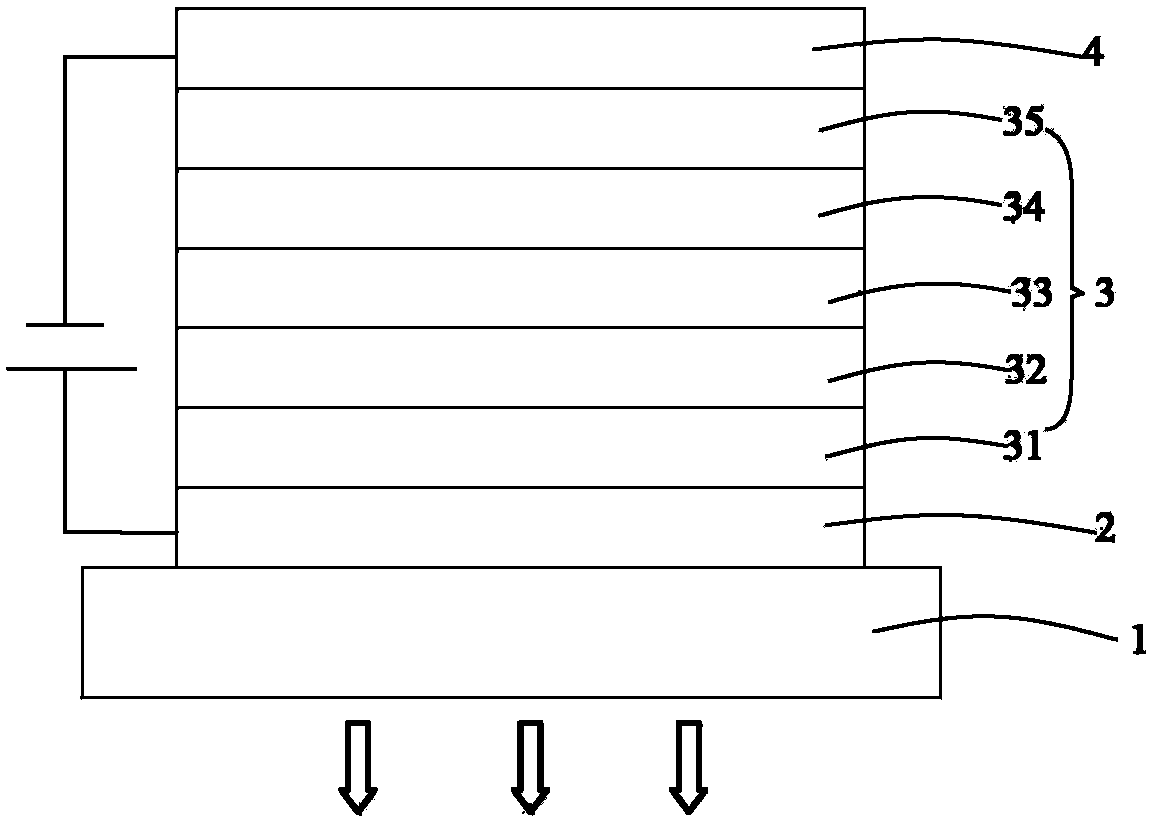

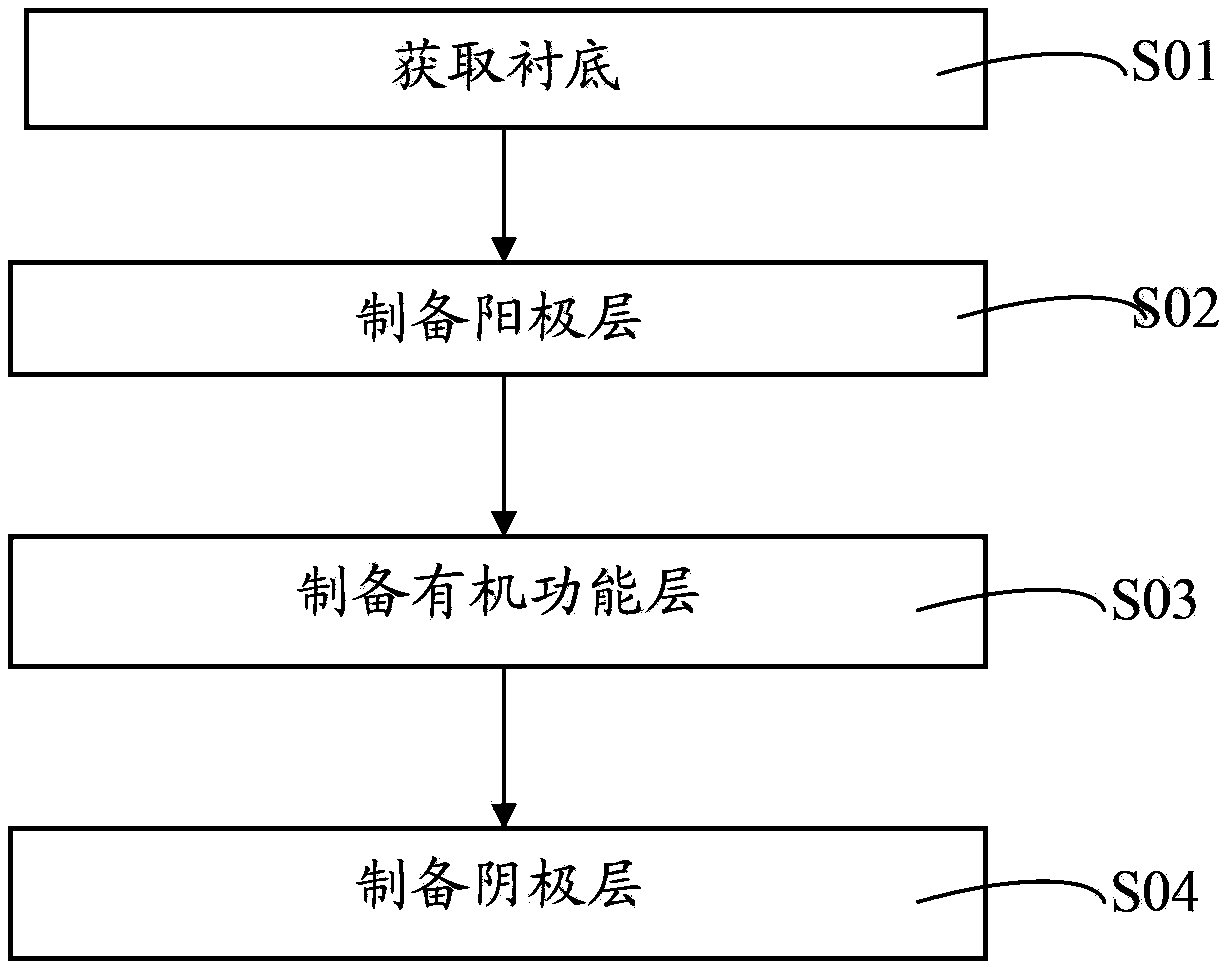

[0029] Correspondingly, the embodiment of the present invention also provides a method for preparing the above-mentioned organic electroluminescent device. The process of the preparation method is as follows figure 2 shown, please also see figure 1 , including the following steps:

[0030] S01. Obtain the substrate: obtain the substrate of the required size according to actual needs as the substrate layer 1;

[0031] S02. Prepare the anode layer 2: plate the anode layer 2 on one surface of the substrate layer 1;

[0032] S03. Preparation of organic functional layer 3: the surface of the anode layer 2 prepared in step S02 opposite to the substrate layer 1 is coated with an organic functional layer 3, wherein the organic functional layer 3 includes a hole transport layer 31 and an external power supply The light-emitting layer 33 that emits light under driving, the hole transport layer 31 is stacked and combined between the anode layer 2 and the light-emitting layer 33, wher...

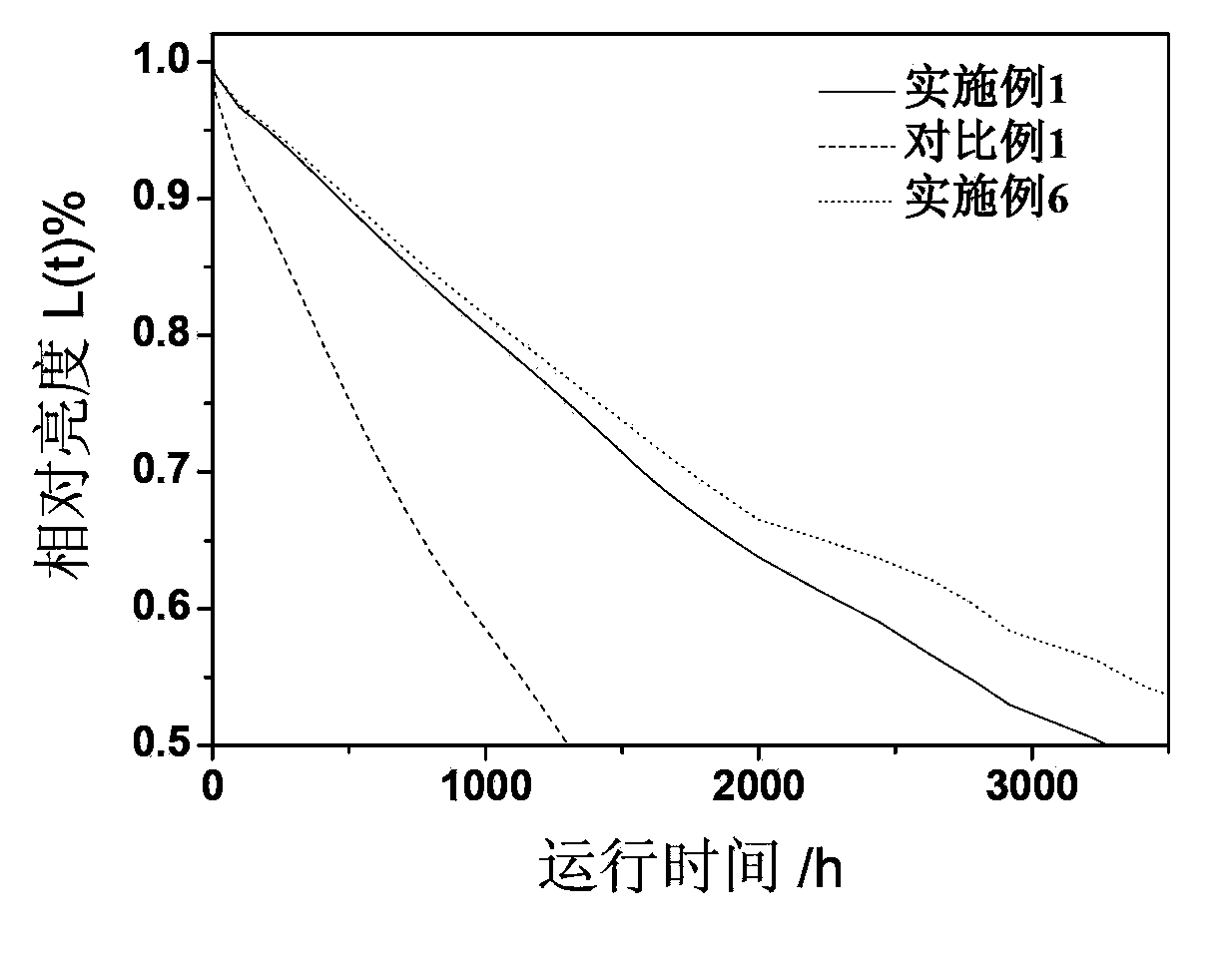

Embodiment 1

[0044] An organic electroluminescence device, its structure is glass substrate / ITO (100nm) / CuI:CuPc (20nm) / TAPC (10nm) / DCJTB:Alq 3 (20nm) / BAlq(10nm) / Cs 2 CO 3 :TPBi(20nm) / Al(100nm). Among them, the hole transport layer is a mixture layer of CuI and CuPc doped with each other, and the doping mass percentage of CuI in the hole transport layer is 2%; the electron transport layer is Cs 2 CO 3 Interdoped mixture layer with TPBi, and Cs 2 CO 3 The mass percentage of doping in the electron transport layer was 2%.

[0045] The preparation method of the organic electroluminescence device comprises the following steps:

[0046] Step S11. Provide a glass substrate: place the glass substrate in deionized water containing detergent for ultrasonic cleaning, and after cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then dry it with nitrogen for use;

[0047] Step S12. In the magnetron sputtering system, prepare an ITO anode layer on the glass substrat...

Embodiment 2

[0053] An organic electroluminescence device, its structure is glass substrate ITO (100nm) / CuI:ZnPc (40nm) / TAPC (10nm) / DCJTB:Alq 3 (20nm) / BAlq(10nm) / Li 2 CO 3 : BPhen(40nm) / Al(100nm). Wherein, the hole transport layer is a mixture layer of CuI and ZnPc doped with each other, and the doping mass percentage of CuI in the hole transport layer is 5%; the electron transport layer is Li 2 CO 3 Interdoped mixture layer with BPhen, and Li 2 CO 3 The mass percentage of doping in the electron transport layer was 5%.

[0054] The preparation method of the organic electroluminescent device comprises the following steps:

[0055] Step S21. Provide a glass substrate: place the glass substrate in deionized water containing detergent for ultrasonic cleaning, and after cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then dry it with nitrogen for use;

[0056] Step S22. In the magnetron sputtering system, prepare an ITO anode layer on the glass substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com