Battery cooling system of novel energy vehicle

An energy and battery technology, applied in the field of battery cooling of new energy vehicles, can solve problems such as low volumetric efficiency and energy efficiency, poor heat dissipation effect, battery capacity, lifespan and energy efficiency reduction, etc., to ensure consistency and accelerate heat dissipation The effect of dissipating and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

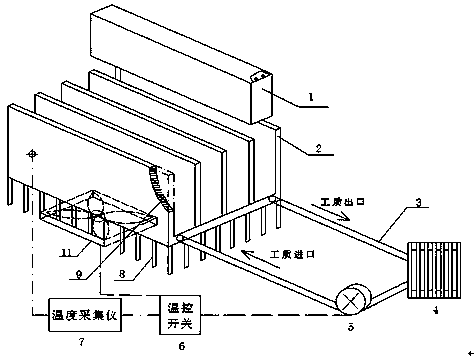

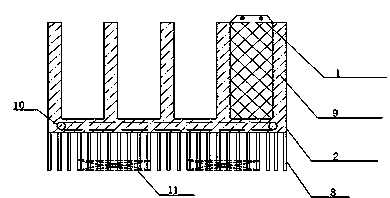

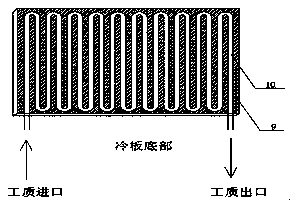

[0016] When the electric vehicle is running, the power battery 1 will be discharged at different discharge rates, which will cause the temperature of the power battery 1 to rise. When the power battery 1 starts to discharge, the heat production is not too large, and the battery temperature will rise slowly. At this time, the temperature control switches 6 and 6' of the system are all disconnected, and the pump 5 and fan 11 of the liquid cooling system are not in operation. The main heat dissipation mode of the power battery 1 is realized through the heat absorption of the phase change material 9 in the housing of the aluminum refrigeration plate 1 and the external heat dissipation of the fins 8 at the bottom of the housing. These two heat dissipation methods can keep the power battery at an appropriate temperature under normal operating conditions and ensure the temperature uniformity of the battery cells. At this time, the system does not need to consume energy, but still has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com