A kind of defoamer composition and preparation method thereof

A composition and defoamer technology, applied in the direction of foam dispersion/prevention, can solve the problems of prolonged production time, slow foam elimination, poor stability, etc., and achieves elimination of harmful foam, fast defoaming, and good room temperature stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for preparing a defoamer composition, the preparation method comprising the following steps: (1) Open the reaction kettle, add 14 kg of polyoxypropylene glycol, 4 kg of cetyl alcohol, polyoxyethylene octylphenol ether at 40 ° C (2) Add 5kg of propylene glycol, 6kg of diethylamine, and 115kg of deionized water to the reactor, and stir evenly; (3) Raise the temperature of the mixture in the reactor to 70°C and add wood 2kg of cellulose, continue to stir until uniform; (4) Homogenize the mixed solution, the homogenization pressure is 14MPa, the homogenization time is 20min, cool after the homogenization is completed, and prepare the defoamer composition.

Embodiment 2

[0014] A method for preparing a defoamer composition, the preparation method comprising the following steps: (1) Open the reaction kettle, add 15 kg of polyoxypropylene glycol, 3 kg of cetyl alcohol, polyoxyethylene octylphenol ether at 40 ° C (2) Add 6kg of propylene glycol, 4kg of diethylamine, and 120kg of deionized water to the reactor, and stir evenly; (3) Raise the temperature of the mixture in the reactor to 70°C and add wood 3kg of cellulose, continue to stir until uniform; (4) Homogenize the mixed solution, the homogenization pressure is 16MPa, the homogenization time is 20min, cool after the homogenization is completed, and prepare the defoamer composition.

Embodiment 3

[0016] A method for preparing a defoamer composition, the preparation method comprising the following steps: (1) Open the reaction kettle, add 17 kg of polyoxypropylene glycol, 3 kg of cetyl alcohol, polyoxyethylene octylphenol ether at 40 ° C (2) Add 5kg of propylene glycol, 5kg of diethylamine, and 110kg of deionized water to the reactor, and stir evenly; (3) Raise the temperature of the mixture in the reactor to 70°C and add wood 2kg of cellulose, continue to stir until uniform; (4) Homogenize the mixed solution, the homogenization pressure is 12MPa, the homogenization time is 20min, cool after the homogenization is completed, and prepare the defoamer composition.

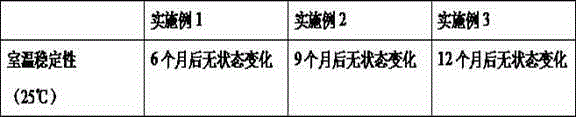

[0017] Place the defoamer compositions of Example 1, Example 2, and Example 3 at 25°C for 6 months, 9 months, and 12 months respectively, and observe the presence or absence of Example 1, Example 2, and Example 3 state change.

[0018] Get four measuring cylinders in addition, add 2wt% sodium tetradecyl sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com