Process and equipment for preparing chloropentane

A chloropentane and a preparation process technology, applied in the field of preparation technology and equipment of chloropentane, can solve the problems of unstable hydrogen chloride gas release, affecting the content and yield of chloropentane, potential safety hazards and the like , to achieve the effect of considerable economic benefits, alleviation of environmental pressure, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

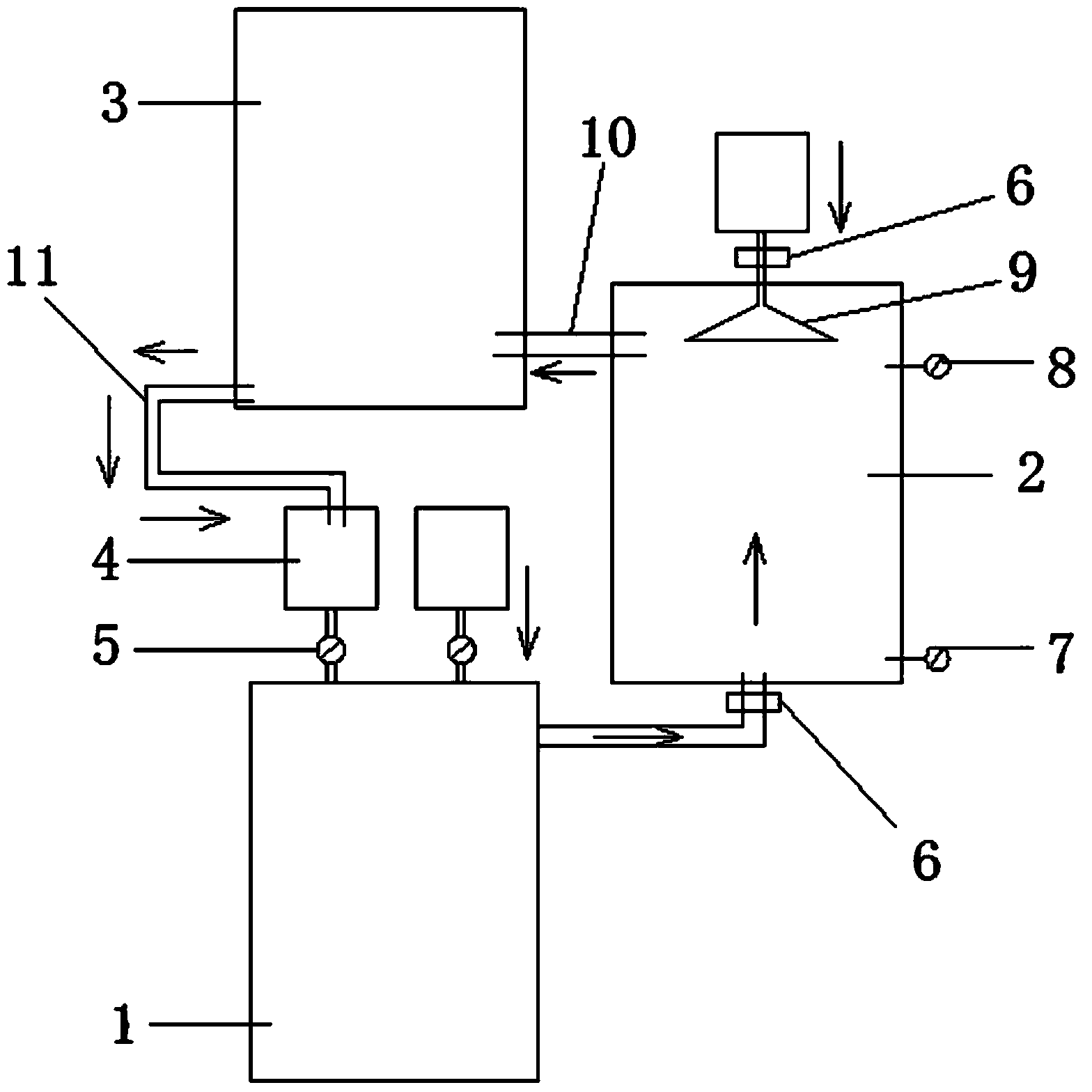

Method used

Image

Examples

Embodiment 4-10

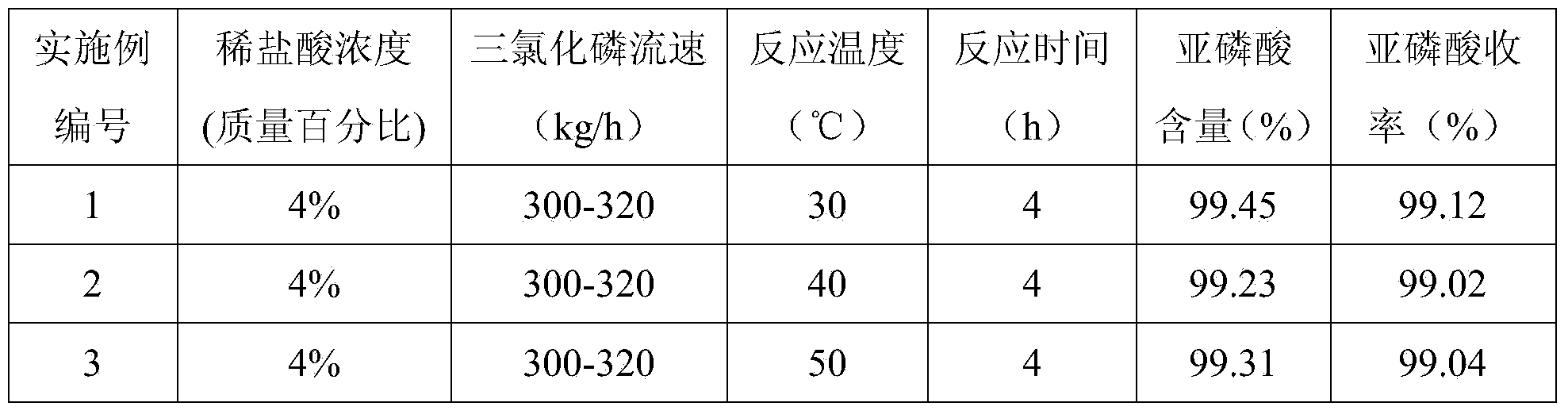

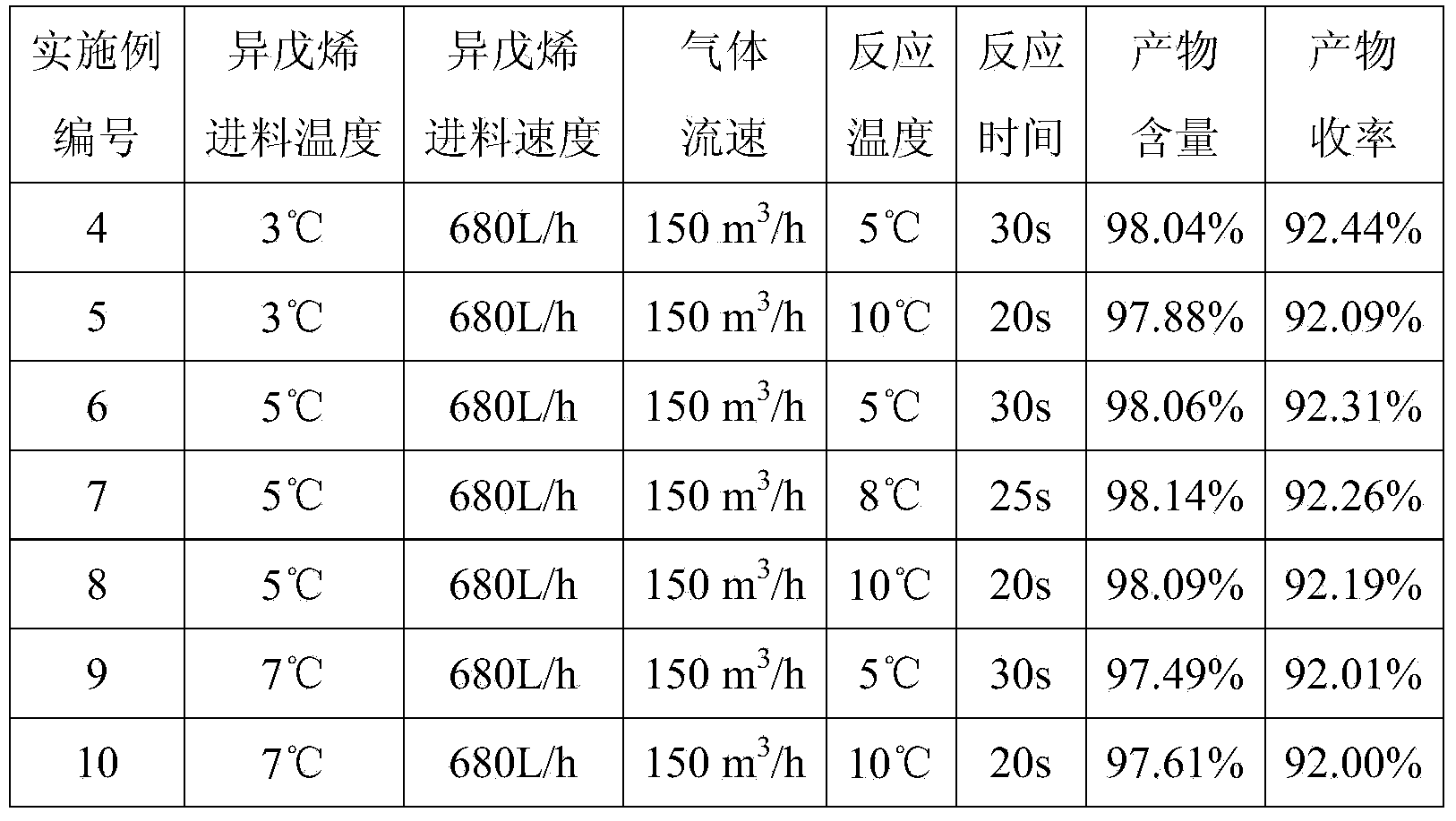

[0033] The influence of embodiment 4-10 temperature on isopentene addition reaction

[0034] The product chloropentane in embodiment 4-10 is assayed, what adopt is the gas chromatograph with hydrogen flame, and the parameter of concrete setting is:

[0035] Chromatographic column: 30m×0.3mm, film thickness 0.45μm, 0V-01 capillary column, sensitivity (yang)=1, split ratio 1:100, carrier gas is nitrogen, detection chamber temperature 180°C, vaporization chamber temperature 180°C, column The initial temperature was 50°C, kept for 2 minutes, and then raised to 100°C at a rate of 10°C / min.

[0036] See Table 2 for the effect of temperature on the addition reaction of isopentene.

[0037] The influence of table 2 temperature on isopentene addition reaction

[0038]

[0039] It can be seen from the test data in the above table that when the feed temperature of isopentene is 3-7°C and the flow rate is 680L / h, the flow rate of hydrogen chloride gas is 150m 3 / h, when the gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com