Method for preparing microcrystalline cellulose for toothpaste

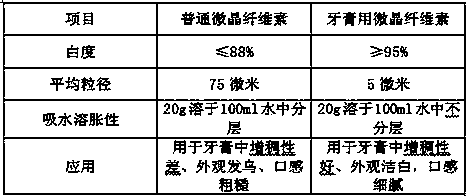

A technology of microcrystalline cellulose and toothpaste, applied in dentistry, medical science, oral care, etc., can solve the problems of insufficient particle size, insufficient whiteness, and insufficient thickening, and achieve high water absorption and enhanced viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Hydrolysis: Put 2500Kg of drinking water in the reaction kettle, open the industrial hydrochloric acid metering tank, put in 46kg of 30% industrial hydrochloric acid to make the acidity 0.2mol / L, turn on the steam and heat to 60°C, close the steam inlet valve, start stirring, and tear the 150kg of refined cotton (average degree of polymerization is 1600, whiteness greater than 85) and 100kg of wood pulp into small flakes, open the steam valve and raise the temperature to 100°C, and carry out hydrolysis reaction at this temperature for 15 minutes.

[0017] Bleaching: Cool down to 80°C, take 5000ml of 30% hydrogen peroxide solution and add it dropwise into the reaction kettle, stirring while adding. After the dropwise addition was completed, the temperature was raised to 95° C., and the reaction was continued for 10 minutes.

[0018] Press filter washing: open the bottom valve of the reaction kettle, and discharge the material in the storage tank of the filter press post ...

Embodiment 2

[0023] Hydrolysis: Put 2500Kg of drinking water in the reaction kettle, open the industrial hydrochloric acid metering tank, put in 52kg of 30% industrial hydrochloric acid, the acidity of industrial hydrochloric acid is 0.23mol / L, turn on steam and heat to 80°C, close the steam inlet valve, start stirring, Take 150kg of refined cotton (average degree of polymerization 2000, whiteness greater than 85) and 100kg of wood pulp torn into small slices, open the steam valve and raise the temperature to 100°C, and carry out hydrolysis reaction at this temperature for 15 minutes.

[0024] Bleaching: Cool down to 85°C, take 5000ml of 30% hydrogen peroxide solution and add it dropwise into the reaction kettle, stirring while adding. After the dropwise addition, the temperature was raised to 97° C., and the reaction was continued for 10 minutes.

[0025] Press filter washing: open the bottom valve of the reaction kettle, and discharge the material in the storage tank of the filter press ...

Embodiment 3

[0030] Hydrolysis: Put 2500Kg of drinking water in the reaction kettle, open the industrial hydrochloric acid metering tank, put in 48kg of 30% industrial hydrochloric acid, the acidity of industrial hydrochloric acid is 0.21mol / L, turn on steam and heat to 68°C, close the steam inlet valve, start stirring, Take 150kg of refined cotton (average degree of polymerization 1700, whiteness greater than 85) and 100kg of wood pulp torn into small slices, open the steam valve and heat up to 100°C, and carry out hydrolysis reaction at this temperature for 15 minutes.

[0031] Bleaching: Cool down to 82°C, take 5000ml of 30% hydrogen peroxide solution and add it dropwise into the reaction kettle, stirring while adding. After the dropwise addition, the temperature was raised to 96° C., and the reaction was continued for 10 minutes.

[0032] Press filter washing: open the bottom valve of the reaction kettle, and discharge the material in the storage tank of the filter press post for stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com