Flame retardant environment-friendly polysulfide sealant and production method of sealant

A polysulfide sealant and polysulfide technology are applied in epoxy resin adhesives, chemical instruments and methods, adhesives, etc., which can solve problems such as potential safety hazards, and achieve the effects of good mold resistance and broad-spectrum mold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

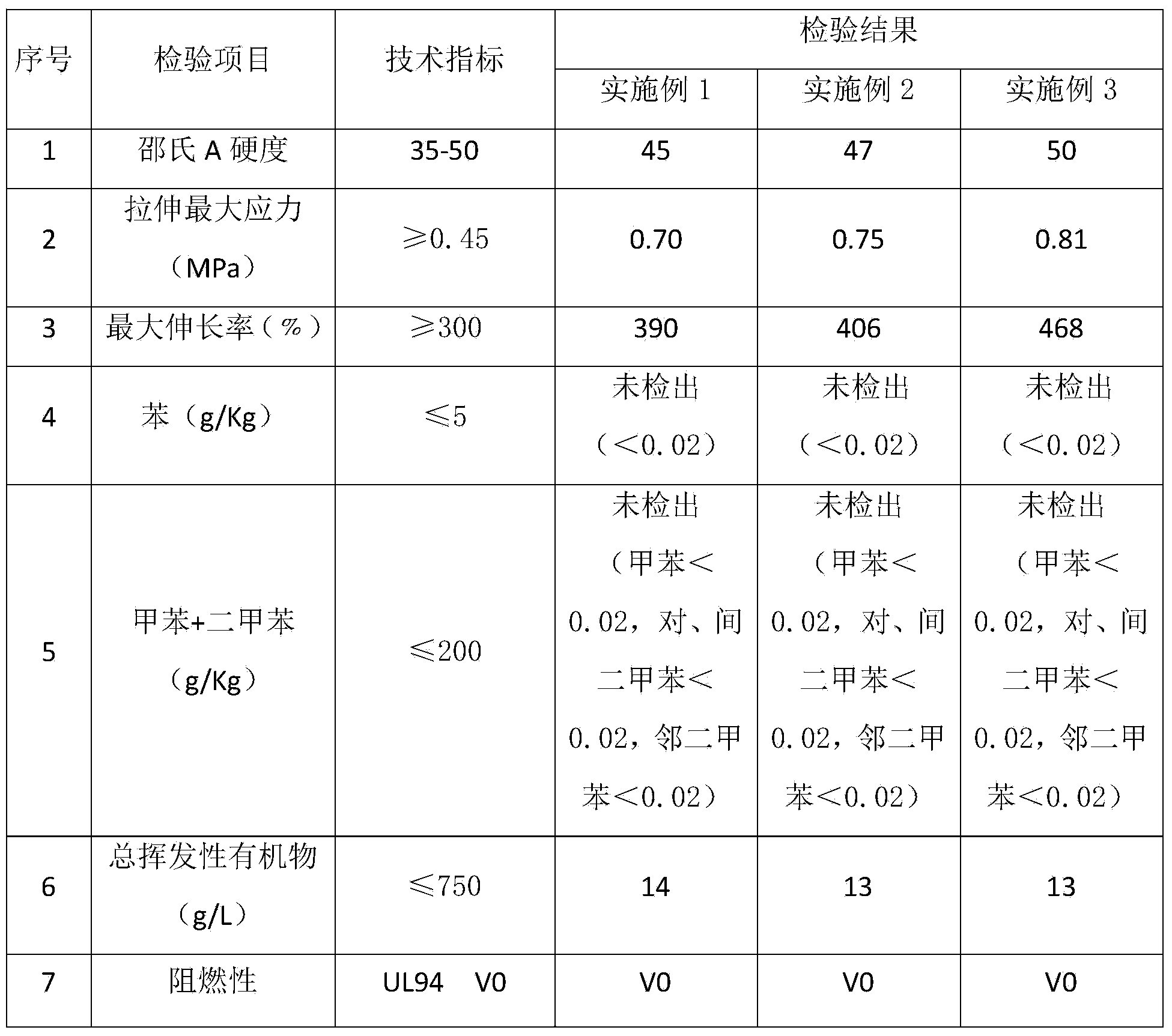

Examples

Embodiment 1

[0023] The preparation of embodiment 1 flame-retardant environment-friendly polysulfide sealant

[0024] Based on the basis of 1 part as 1 kg, weigh the various ingredients of component A glue according to the specific formula ratio as follows: 100 parts of polysulfide glue, 20 parts of butyl benzyl phthalate, 20 parts of nano-calcium carbonate, hydrogen 5 parts of alumina, 5 parts of nano titanium dioxide, 5 parts of epoxy resin, 20 parts of carbon black, 0.5 parts of coupling agent;

[0025] Taking 1 part as 1 kilogram, weigh the various ingredients of the B component glue according to the specific formula ratio as follows: 50 parts of manganese dioxide, 20 parts of butyl benzyl phthalate, and 1 part of diphenylguanidine;

[0026] 〈3〉Add the raw materials of component A to the planetary mixer in the order of polysulfide glue-nano-calcium carbonate-aluminum hydroxide-nano-titanium dioxide-carbon black-butyl benzyl phthalate-epoxy resin-coupling agent Stir for 15 minutes, le...

Embodiment 2

[0031] The preparation of embodiment 2 flame-retardant environment-friendly polysulfide sealant

[0032] On the basis of 1 part as 1 kg, weigh the various ingredients of component A glue according to the specific formula ratio as follows: 110 parts of polysulfide glue, 25 parts of butyl benzyl phthalate, 25 parts of nano-calcium carbonate, hydrogen 6 parts of alumina, 8 parts of nano titanium dioxide, 6 parts of epoxy resin, 24 parts of carbon black, 0.7 parts of coupling agent;

[0033] Taking 1 part as 1 kg, weigh the various ingredients of component B glue according to the specific formula ratio as follows: 55 parts of manganese dioxide, 25 parts of butyl benzyl phthalate, and 1.5 parts of diphenylguanidine;

[0034] 〈3〉Add the raw materials of component A to the planetary mixer in the order of polysulfide glue-nano-calcium carbonate-aluminum hydroxide-nano-titanium dioxide-carbon black-butyl benzyl phthalate-epoxy resin-coupling agent Stir for 15 minutes, let stand for ...

Embodiment 3

[0039] Embodiment 3 preparation of flame-retardant environment-friendly polysulfide sealant

[0040] Based on the basis of 1 part as 1 kg, weigh the various ingredients of component A glue according to the specific formula ratio as follows: 120 parts of polysulfide glue, 25 parts of butyl benzyl phthalate, 30 parts of nano-calcium carbonate, hydrogen 7 parts of alumina, 10 parts of nano titanium dioxide, 7 parts of epoxy resin, 28 parts of carbon black, 0.9 parts of coupling agent;

[0041] Taking 1 part as 1 kg, weigh the various ingredients of component B glue according to the specific formula ratio as follows: 60 parts of manganese dioxide, 30 parts of butyl benzyl phthalate, and 2 parts of diphenylguanidine;

[0042]〈3〉Add the raw materials of component A to the planetary mixer in the order of polysulfide glue-nano-calcium carbonate-aluminum hydroxide-nano-titanium dioxide-carbon black-butyl benzyl phthalate-epoxy resin-coupling agent Stir for 15 minutes, let stand for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com