Preparation method for N-Zr co-doping of zinc oxide thin film

A technology of zinc oxide thin film and oxygen source, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of difficult to achieve precise doping, affecting film thickness and uniformity, and film doping, etc. Achieve the effects of promoting formation, improving stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

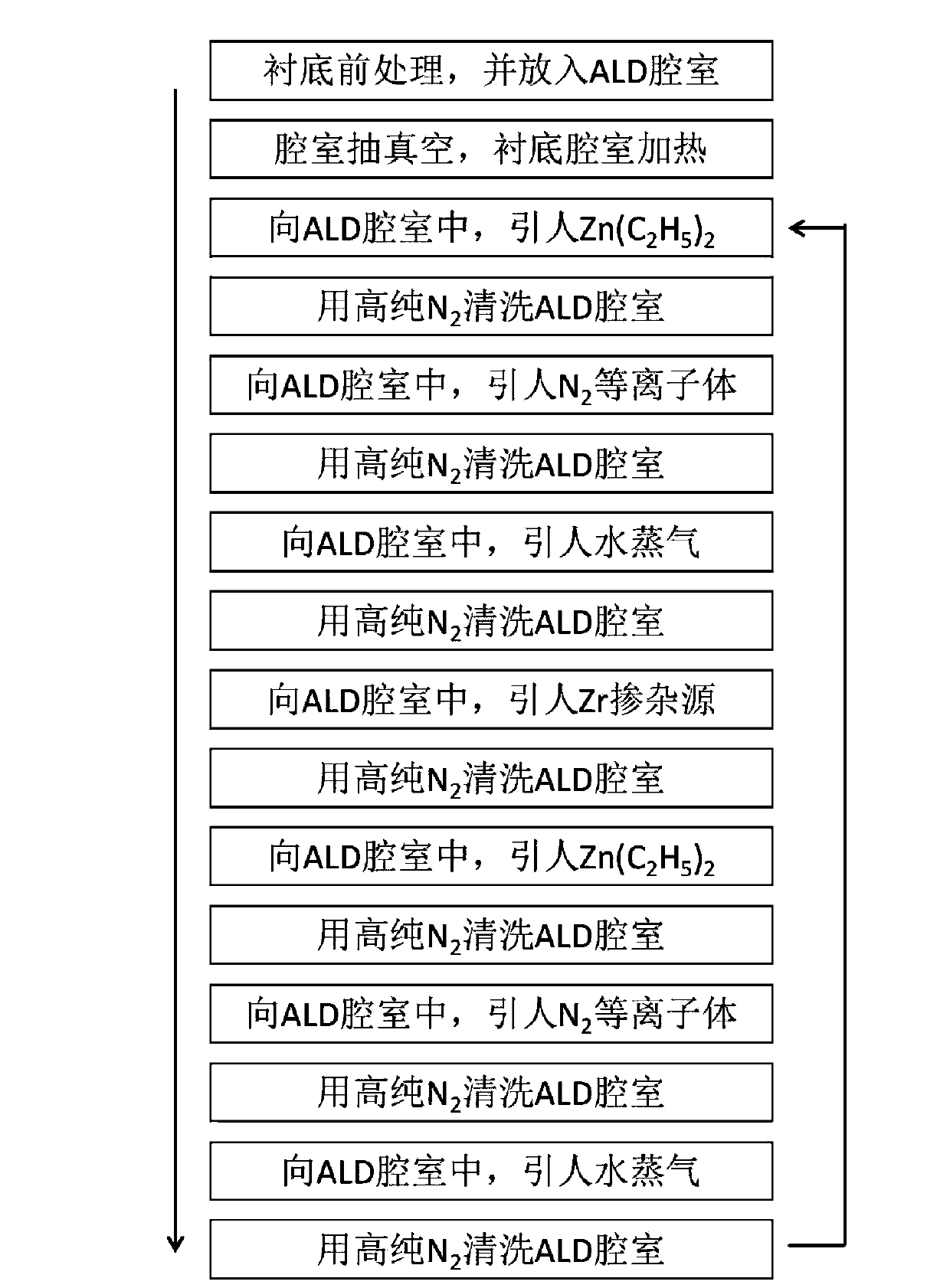

[0008] see figure 1 As shown, the preparation method for N-Zr co-doped zinc oxide film provided by the embodiment of the present invention includes: treating a silicon substrate or a glass substrate with concentrated sulfuric acid hydrogen peroxide, and then ultrasonically cleaning with ultrapure water, N 2 Blow dry, wherein concentrated sulfuric acid:hydrogen peroxide=4:1. Put the substrate into the atomic layer deposition chamber, turn on the atomic layer deposition equipment, adjust the working parameters, vacuumize and heat the bottom to achieve various working environments required for the experiment; conduct multiple groups of N-Zr co-doped zinc oxide thin films Composite deposition, namely Zn(C 2 h 5 ) 2 / N 2 / plasma N 2 / N 2 / H 2 O / N 2 / (CH 3 CH 2 O) 4 Zr / N 2 / Zn(C 2 h 5 ) 2 / N 2 / plasma N 2 / N 2 / H 2 O / N 2 =0.15s / 50s / 10s / 50s / 0.07s / 50s / 0.08s / 50s / 0.08s / 50s / 10s / 50s / 0.07s / 50s. Wherein the flow rate of nitrogen is 1sccm-1000sccm, preferably 15sccm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com