Mercury-free button cell cathode cap material and preparation method thereof

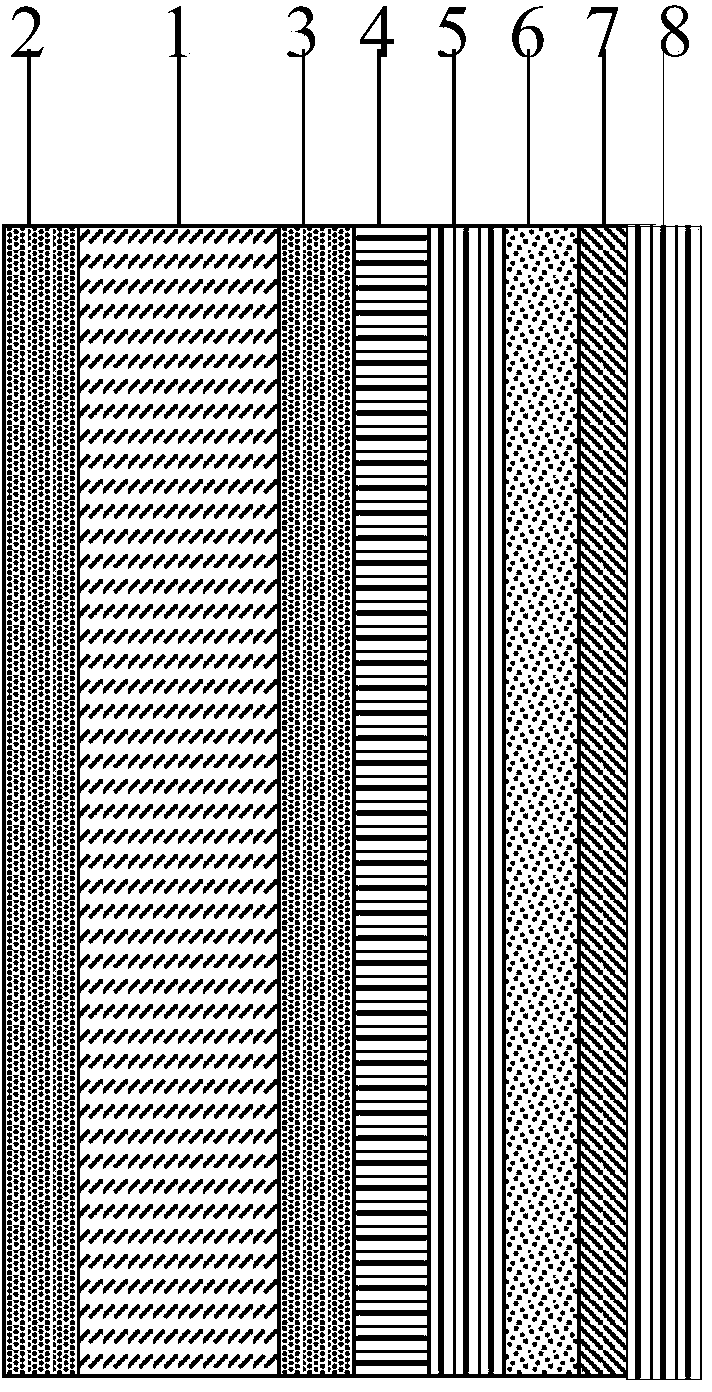

A button battery and negative electrode cover technology is applied to the negative electrode cover material of mercury-free alkaline zinc-manganese button battery and its preparation, and the field of mercury-free button battery negative electrode cover material and its preparation field, which can solve the problems of coating peeling, sticking and grinding tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The specific preparation process of the above-mentioned steel strip: select the SPCC cold-rolled low-carbon steel strip with a thickness of 0.25 mm produced by Shanghai Baosteel as the electroplating substrate. Its chemical composition is (% represents weight percentage):

[0067]

[0068] 1. Treat the low carbon steel strip before plating

[0069] In order to have a good bond between the coating and the substrate, the cathode substrate must be carefully pretreated before electroplating. Since the surface of the low-carbon steel strip used is relatively flat, there is no need for grinding and mechanical polishing before nickel plating, and degreasing and activation treatment are directly carried out. The method of chemical high-temperature degreasing and electrolytic degreasing is adopted. After the degreasing is complete, the surface of the sample is rinsed with distilled water, and then placed in an activator for activation. After taking out the sample and washin...

Embodiment 2

[0148] Preparation method: select the same substrate as in Example 1, adopt the same pre-plating treatment as in Example 1, and electroplate nickel coating, copper coating, first zinc coating, tin coating, indium coating and second zinc coating respectively according to the method of Example 1 Plating, wherein the thickness of the nickel coating is 0.3 μm, the thickness of the copper coating is 1.5 μm, the thickness of the first zinc coating is 0.5 μm, the thickness of the tin coating is 3 μm, the thickness of the indium coating is 0.1 μm, and the thickness of the second zinc coating is 1.5 μm, and then Same heat treatment and mechanical rolling as in Example 1.

Embodiment 3

[0156] Preparation method: select the same substrate as in Example 1, adopt the same pre-plating treatment as in Example 1, and electroplate nickel coating, copper coating, first zinc coating, tin coating, indium coating and second zinc coating respectively according to the method of Example 1 The coatings, wherein the thickness of the nickel coating is 1.0 μm, the thickness of the copper coating is 2.5 μm, the thickness of the first zinc coating is 2 μm, and the thickness of the tin coating is 5 μm.

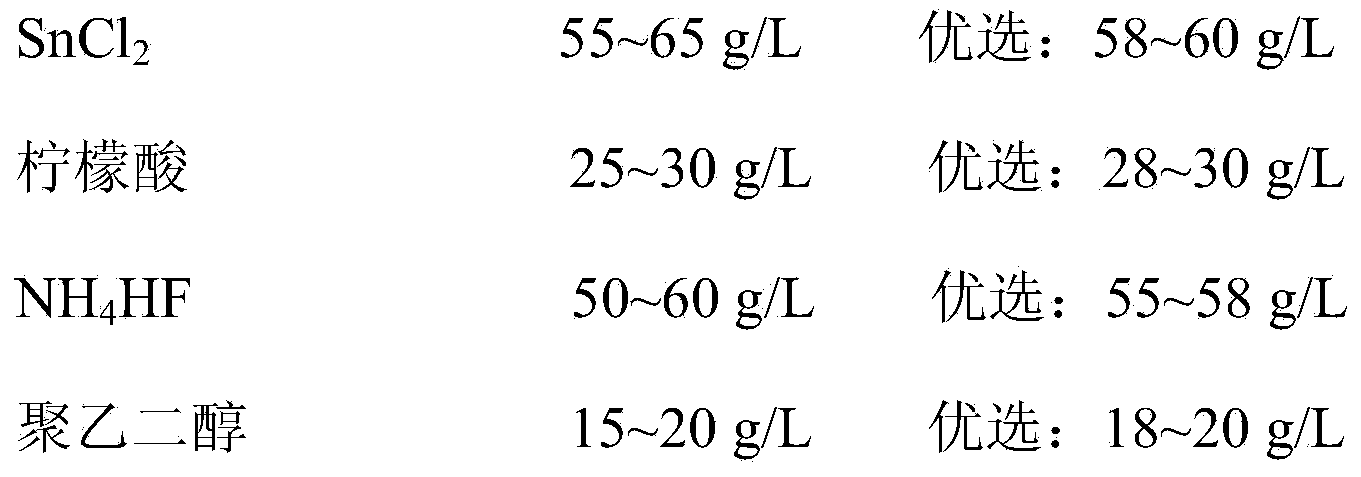

[0157] The composition of the plating solution for electroplating indium on the surface of the tin layer is:

[0158]

[0159] DC electrodeposition process parameters:

[0160]

[0161] Under the above conditions, an indium coating with a thickness of 0.30 μm was prepared on the tin coating.

[0162] Using the method of Example 1, a second zinc coating was electroplated on the surface of the indium coating. The thickness of the second zinc layer was 2.5 μm, and then the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com