Brush Friction Coefficient Test Bench and Its Measuring Method

A friction coefficient, test bench technology, applied in measuring devices, instruments, mechanical devices, etc., can solve problems such as low measurement accuracy, and achieve the effects of strong anti-interference ability, simple and convenient operation, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

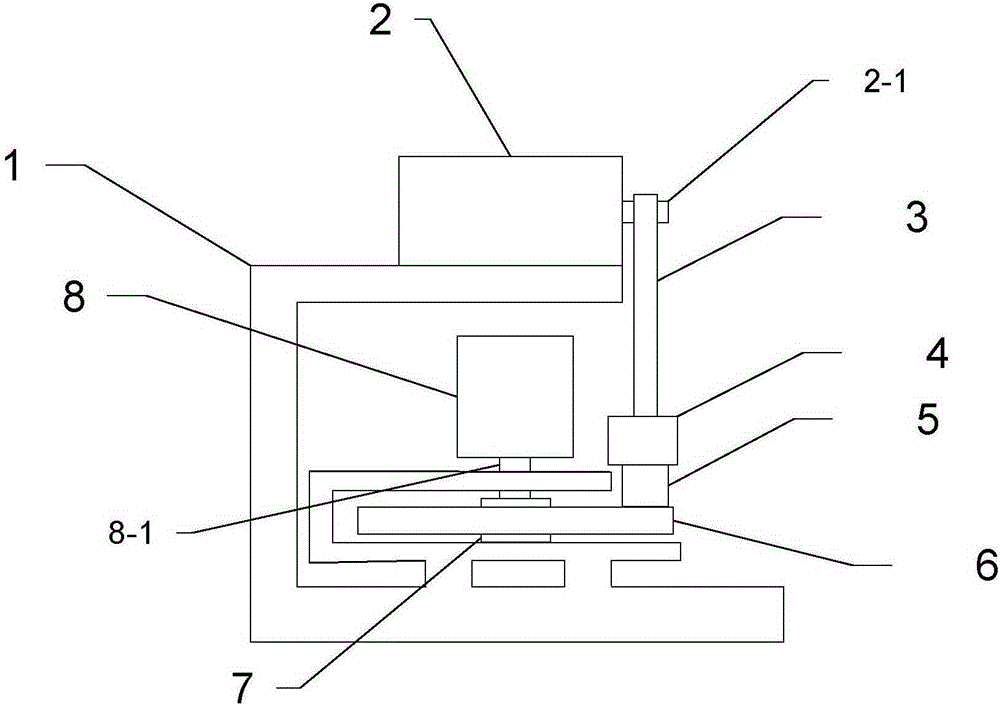

[0030] Specific implementation mode one: combine figure 1 Describe this embodiment, the brush friction coefficient test bench described in this embodiment, the test bench includes a test tool and a control system;

[0031] The test tooling includes a support base 1, a torque sensor 2, a lever lever 3, a pressure sensor 4, a brush mounting tool 5, a copper inlaid turntable 6, a radial bearing 7 and a drag motor 8;

[0032] The test bench support seat 1 is a three-layer support seat, and a torque sensor 2 is arranged on the top layer of the test bench support seat 1, and the output shaft 2-1 of the torque sensor 2 is vertically connected with the top of the arm bar 3, and the arm bar The bottom end of 3 is fixedly connected with the upper surface of pressure sensor 4,

[0033] The brush mounting tool 5 is divided into an upper part and a lower part, and the upper part and the lower part are connected by threads; the lower surface of the pressure sensor 4 is fixedly connected wi...

specific Embodiment approach 2

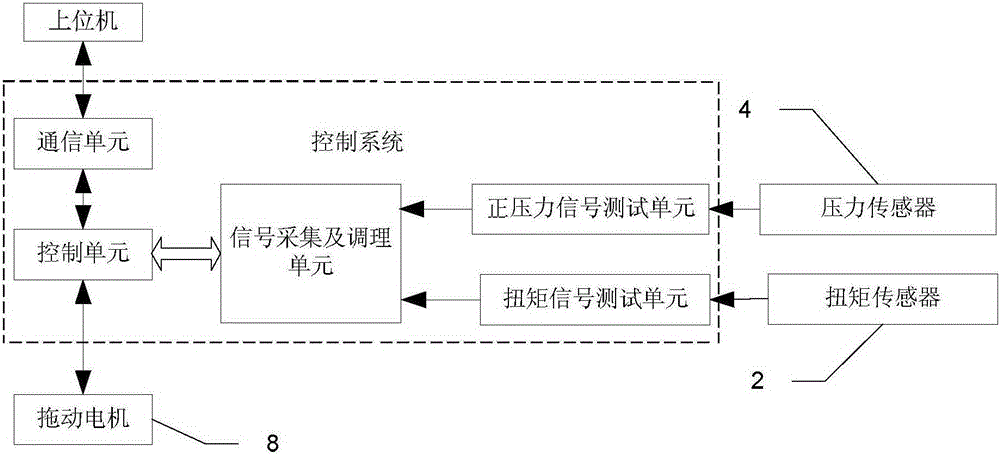

[0041] Specific implementation mode two: combination figure 2 This embodiment is described. This embodiment is a further limitation of the brush friction coefficient test bench described in Embodiment 1. The control system includes a torque signal test unit, a positive pressure signal test unit, a signal acquisition and conditioning unit, and a control system. and processing unit and communication unit;

[0042] a torque signal testing unit, configured to receive the torque signal measured by the torque sensor 2;

[0043] A positive pressure signal testing unit, configured to receive the positive pressure signal measured by the pressure sensor 4;

[0044] The signal acquisition and conditioning unit is used to sample the received torque signal and positive pressure signal, condition the sampled signal, and send it to the control and processing unit;

[0045] The control and processing unit is used to control the rotation of the dragging motor 8, and is also used to select a...

specific Embodiment approach 3

[0048] Embodiment 3: This embodiment is a further limitation of the brush friction coefficient test bench described in Embodiment 3, and the torque sensor 2 is realized by a loaded dynamometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com