Tooth preparation-based data flexible fusion method

A preparation and data technology, applied in image data processing, 3D image processing, 3D modeling, etc., can solve the problems of inability to obtain internal data information of the model, loss of detailed features, low surface accuracy, etc., and achieve a simple and efficient fusion algorithm , The fusion process is smooth and stable, without the effect of interlacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific implementation plan

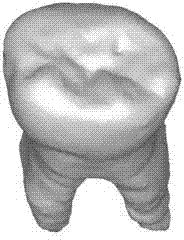

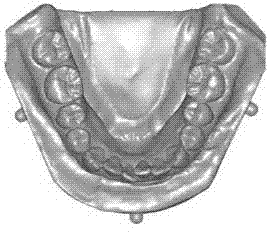

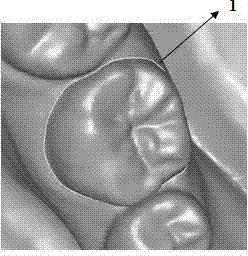

[0026] Step 1. Data acquisition and pre-processing: Obtain the two-dimensional slice data of the patient's jaw by CT scanning, then take the mold to fill the upper and lower jaw plaster model, and use the structural optical scanner to collect the data of the plaster model to obtain the 3D point cloud data. Through the three-dimensional data reconstruction of the collected two types of data, an accurate triangular mesh model of the upper and lower jaw is constructed. Due to the inevitably encountering defects such as noise and scanning blind areas during scanning, it is necessary to preprocess the reconstruction model (de-noise, triangulation, hole repair, etc.). CT 3D reconstruction and structured light point cloud data 3D reconstruction are as follows: figure 1 , figure 2 Shown.

[0027] Step 2. Extraction of the fusion area: The entire dental model scanned by structured light is not all effective for the design process. First, the model need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com