Method for machining high-strength steel hot stamping formed parts

A hot stamping forming and part processing technology is applied in the processing field of realizing the above-mentioned parts trimming and punching and collision energy absorption area, which can solve the problems of low production efficiency, high investment cost and high strength, so as to reduce production difficulty and improve collision performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in further detail:

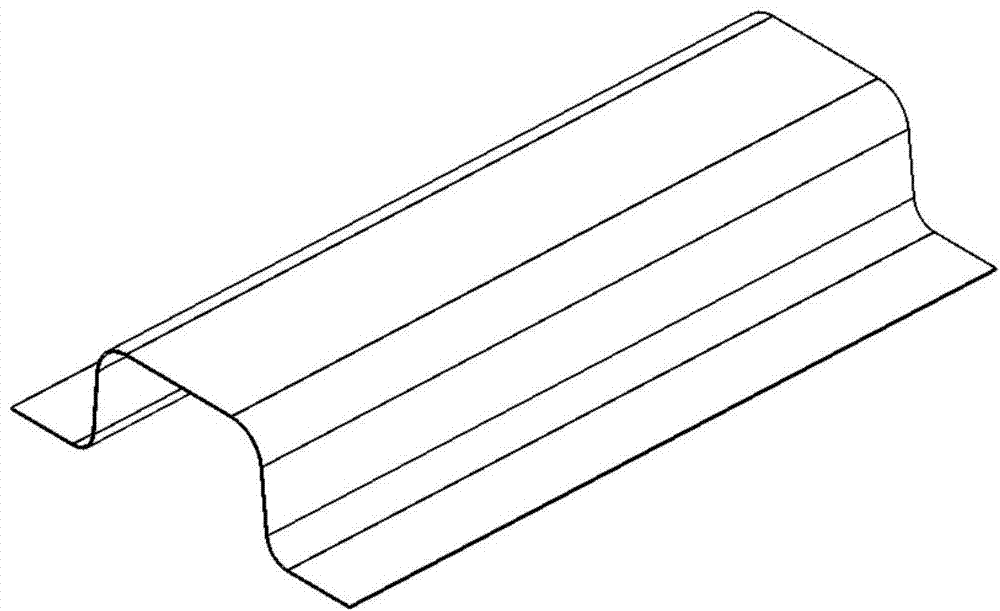

[0018] figure 1 It is a part after hot stamping forming, and the overall performance is uniform, and the performance is: strength 1500MPa, shaping 5%. need according to figure 2 The performance requirements are changed to improve the collision performance and cutting edge punching performance by changing the local strong shaping.

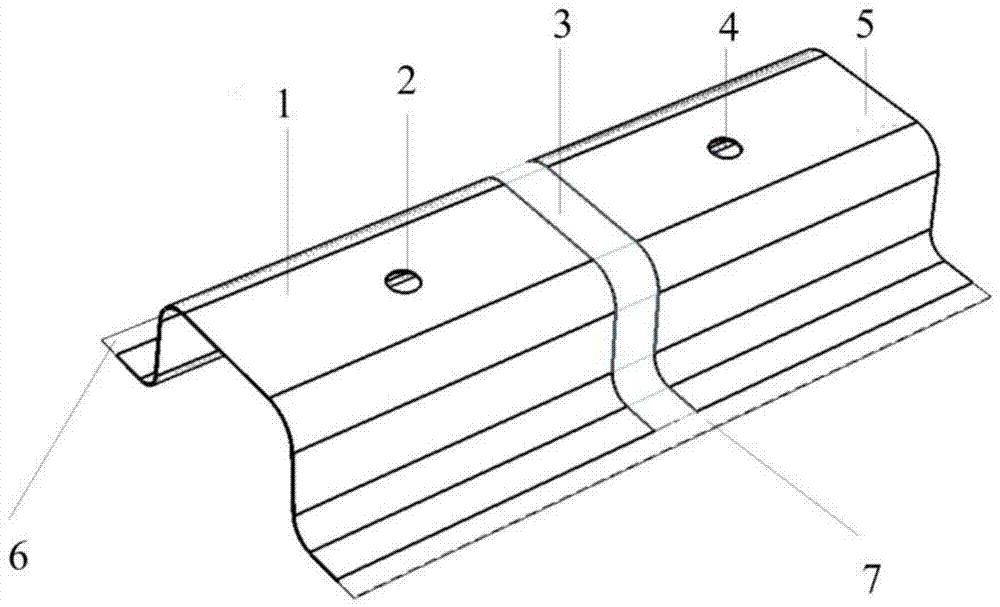

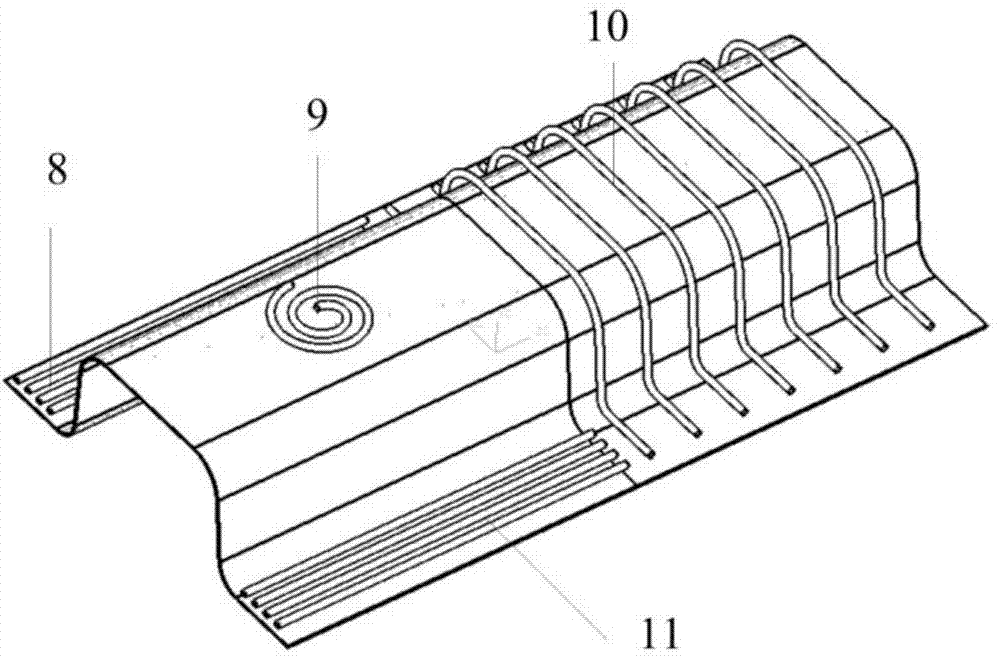

[0019] According to the three-dimensional structure and performance requirements of parts, such as figure 2 , such as according to the local needs of trimming punching and performance requirements of energy-absorbing parts, determine the gradient distribution state of part performance. figure 2 In the figure, the performance requirements of part 1 in the left half are: strength 1500MPa, elongation 5%; the performance requirements of impact energy-absorbing area 5 in the right half part are: strength 600MPa, elo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com