Method for efficiently processing high-quality micro hole with large ratio of pit-depth to pit-diameter through femtosecond laser

A femtosecond laser, high-efficiency technology, applied in the field of laser applications, can solve the problems of poor quality, small aspect ratio, low efficiency of femtosecond laser processing of micro-holes, etc., achieve high-efficiency micro-hole processing, improve aspect ratio and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

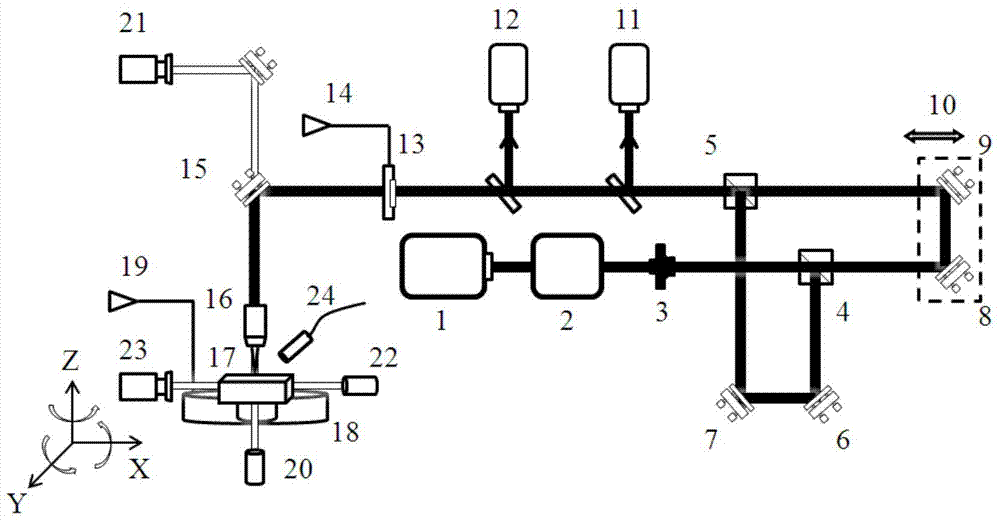

[0023] Taking the processing of micropores of PMMA polymer (polymethyl methacrylate) as an example, the femtosecond laser visible light double-pulse processing method of the present invention is adopted, and the specific application equipment is as follows:

[0024] Femtosecond laser 1 is a laser produced by Spectrum Physics in the United States. The laser wavelength is 800nm, the pulse width is 50fs, the repetition frequency is 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized.

[0025] The femtosecond laser optical parametric amplifier 2 is TOPAS-C produced by American Light Conversion Company, which can continuously adjust the 800nm femtosecond laser pulse in the wavelength range of 290-2600nm with an adjustment accuracy of 0.1nm.

[0026] The structural components of the Michelson interferometer include: a dichroic prism 4 , a light combining prism 5 , a first reflector 6 , a second reflector 7 , a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com