Aerobic nitration granule sludge long-term storage and activity recovery method

An aerobic granular sludge and granular sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. and other problems, to achieve the effect of complete activated sludge particles, easy operation and short recovery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

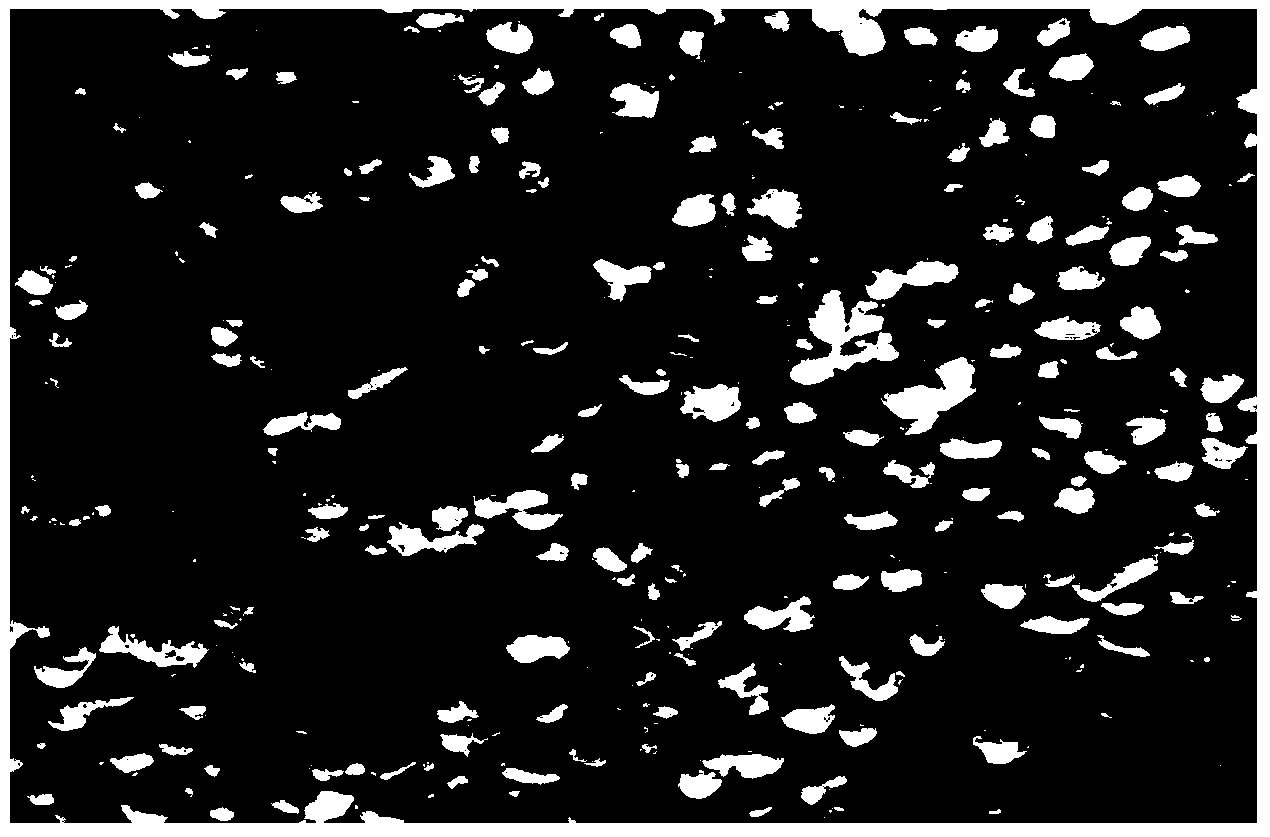

Image

Examples

Embodiment 1

[0019] The volume of the SBR reactor used was 21 L.

[0020] 1. Determination of COD treatment capacity and ammonia nitrogen removal capacity of aerobic granular sludge before storage. The aerobic granular sludge culture substrate in the SBR reactor uses sodium acetate as the only carbon source, the COD concentration is 700-800mg / L, the ammonia nitrogen concentration is 70-80mg / L, the phosphate concentration is 10mg / L, and the calcium ion concentration is 20mg. / L, pH=7.5, aeration rate is 0.3m 3 / h. Every 6 hours is a cycle, and 2 cycles are run every day. After each cycle, the removal capacity of COD and ammonia nitrogen is measured, and the removal capacity of COD and ammonia nitrogen can reach more than 90%.

[0021] 2. Preservation method of aerobic granular sludge: Take it out of the SBR reactor, wash it with distilled water 3 times, remove the nutrients on the surface, store it in a petri dish or other container (no need to seal), and then put Put it into a freeze dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com