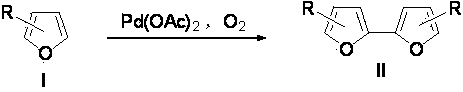

Synthetic method for furan coupling compound

A synthetic method and furan coupling technology, which is applied in the field of synthesis of furan coupling compounds, achieves the effects of high regioselectivity, wide substrate adaptability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] IIa

[0016] In a 10mL single-necked flask was added Pd(OAc) 2 (22.4 mg, 10 mmol %), sealed and evacuated, replaced the air in the bottle with an oxygen balloon, and filled the flask with oxygen. Then, DMSO (1.5 mL) and TFA (75 μL, 1 mmol) were sequentially added to the flask via syringe under oxygen atmosphere, and the reaction mixture was stirred homogeneously at room temperature. Add 2-ethylfuran (105 μL, 1 mmol) to the well-stirred flask, react at room temperature for 24 h, and detect the reaction with a TLC plate until the reaction of the raw material is complete. A small amount of NaHCO was then added to the reaction mixture 3 Neutralize excess TFA, extract three times with ether, combine organic phases; wash with water, wash with saturated brine, wash with MgSO 4 Dry, concentrate under reduced pressure, and separate by column chromatography with n-hexane as the eluent to obtain self-coupling product IIa (76 mg, 80%).

[0017] IR (KBr) υ 3116, 2973, 2933, ...

Embodiment 2

[0019] IIb

[0020] In a 10mL single-necked flask was added Pd(OAc) 2 (22.4 mg, 10 mmol %), sealed and evacuated, replaced the air in the bottle with an oxygen balloon, and filled the flask with oxygen. Then, DMSO (1.5 mL), TFA (75 μL, 1 mmol) were sequentially added to the flask via syringe under an oxygen atmosphere, and the reaction mixture was stirred homogeneously at room temperature. Add 2-benzyloxymethylenefuran (188 mg, 1 mmol) to a well-stirred flask, react at 50°C for 24 hours, and detect the reaction with a TLC plate until the reaction of the raw materials is complete. A small amount of NaHCO was then added to the reaction mixture 3 Neutralize excess TFA, extract three times with ether, combine organic phases; wash with water, wash with saturated brine, wash with MgSO 4 Dry, concentrate under reduced pressure, and separate by column chromatography, using n-hexane / ethyl acetate as the eluent at 1:20, to obtain the self-coupling product IIb (159 mg, 85%).

[0...

Embodiment 3

[0023] IIc

[0024] In a 10mL single-necked flask was added Pd(OAc) 2 (22.4 mg, 10 mmol %), sealed and evacuated, replaced the air in the bottle with an oxygen balloon, and filled the flask with oxygen. Then, DMSO (1.5 mL), TFA (75 μL, 1 mmol) were sequentially added to the flask via syringe under an oxygen atmosphere, and the reaction mixture was stirred homogeneously at room temperature. Add ethyl 2-furan propionate (168 mg, 1 mmol) to the well-stirred flask, react at 50°C for 24 h, and detect the reaction with a TLC plate until the reaction of the raw materials is complete. A small amount of NaHCO was then added to the reaction mixture 3 Neutralize excess TFA, extract three times with ether, combine organic phases; wash with water, wash with saturated brine, wash with MgSO 4 Dry, concentrate under reduced pressure, and separate by column chromatography, using n-hexane / ethyl acetate as the eluent at 1:10, to obtain the self-coupling product IIc (136 mg, 81%).

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com