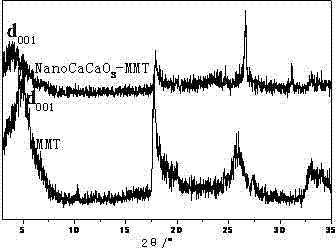

Method for preparing intercalated montmorillonite composite inorganic matter from nano calcium carbonate

A technology of nano calcium carbonate and intercalated montmorillonite, which is applied in inorganic pigment treatment, chemical instruments and methods, dyeing low molecular organic compound treatment and other directions, to achieve the effects of good dispersibility, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 20g of montmorillonite with a cation exchange capacity of 100mg / 100g and a particle size of 80 microns, make a 20% suspension with deionized water, stir ultrasonically for 1 hour at 30°C, add the organic intercalation agent hexadecyltri 0.4 g of methyl ammonium bromide, the temperature was raised to 80° C., and ultrasonic stirring was continued for 4 h to obtain a stable suspension system. Take 150ml concentration of 15% CaCl 2 The solution was added to the suspension at a uniform speed, stirred, the temperature was controlled at 30°C, the addition time was 4h, and CO was introduced at a flow rate of 1L / h 2 Gas for 5 hours, aged for 12 hours to obtain a slurry, centrifuge and filter to obtain a filter cake. Break the filter cake and put it into the 2 Roasting in a gas muffle furnace, the firing temperature is 200°C, the firing time is 2.5h, the material is cooled and discharged, and the agate is ground to obtain the nano-calcium carbonate intercalated montmoril...

Embodiment 2

[0022] Take 20g of montmorillonite with a cation exchange capacity of 150mg / 100g and a particle size of 50 microns, make a 15% suspension with deionized water, stir ultrasonically at 40°C for 2 hours, add the organic intercalation agent hexadecyltri 0.6 g of methyl ammonium bromide, the temperature was raised to 80° C., and ultrasonic stirring was continued for 4 h to obtain a stable suspension system. Take 450ml concentration of 20% CaCl 2 The solution was added to the suspension at a uniform speed, stirred, the temperature was controlled at 50°C, the addition time was 6h, and CO was introduced at a flow rate of 1L / h 2 Gas for 7 hours, aged for 12 hours to obtain a slurry, centrifuge, filter, and obtain a filter cake. Break the filter cake and put it into the 2 Roast in a gas muffle furnace at a temperature of 250°C for a time of 3 hours, cool and discharge, and grind agate to obtain nano-calcium carbonate intercalated montmorillonite composite inorganic matter. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com