High-pressure bottom-blowing refining casting device and method for smelting high-nitrogen steel by using same

A high-nitrogen steel and high-pressure technology is applied in the field of refining and casting devices for efficient production of high-nitrogen steel, which can solve the problems of high production cost, polluted molten steel, slow reaction speed, etc., and achieves good ingot quality, cost saving, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

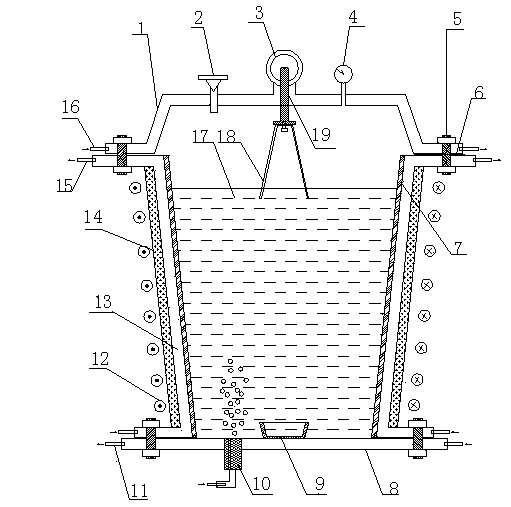

[0043] Embodiment 1 is applicable to a high-pressure bottom blowing refining and casting device for smelting high-nitrogen steel small ingots.

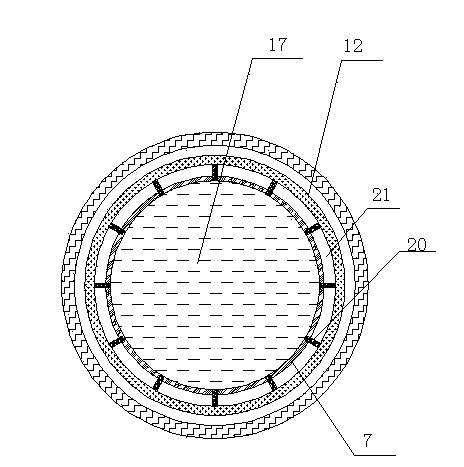

[0044] The induction coil 12 of the high-pressure bottom-blowing refining casting device of this embodiment is made of copper hollow tube, which can generate an intermediate frequency magnetic field of 2500-8000 Hz. The safety refractory layer 14 is magnesia refractory mud material with a thickness of 10mm. The water-cooled copper crucible layer 13 16 water-cooled copper plates 21 and 16 divided refractory sheets 20 are evenly spaced to form a cylinder. The outer diameter of the cylinder is 124mm, the inner diameter is 84mm, and the height is 150mm. The thickness of the water-cooled copper plate 21 is 20mm. MPa, flow rate 10~15m 3 / h, divided refractory sheet 20 is made of refractory mica, 3mm thick, 20mm wide, 150mm high, water-cooled movable bottom plate 8 thick 20mm, diameter 180mm, cooling water flow 10~15m 3 / h, the bottom blowi...

Embodiment 2

[0047] High-pressure bottom blowing refining casting device suitable for smelting high-nitrogen steel ingots:

[0048] The induction coil 12 of the high-pressure bottom-blowing refining casting device of this embodiment is made of copper hollow tube, and the induction coil 12 can generate an intermediate frequency magnetic field of 5000~10000 Hz. The crucible layer 13 is composed of 24 water-cooled copper plates and 24 divided refractory sheets evenly spaced. The outer diameter of the cylinder is 320mm, the inner diameter is 240mm, the height is 400mm, the thickness of the water-cooled copper plate is 40mm, and the internal cooling water pressure is 0.5~0.8MPa, and the flow rate is 40~ 50m 3 / h, divided refractory sheet 20 is made of refractory mica, 5mm thick, 40mm wide, 300mm high, water-cooled movable bottom plate 40mm thick, 340mm in diameter, cooling water flow 40~50m 3 / h, the bottom blowing hole is opened at 60mm eccentricity, the bottom blowing plug 10 is made of magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com