Lanthanum-nitrogen co-penetration rare earth penetration activator

A technology of infiltration agent and rare earth, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effects of easy volatilization and decomposition, reducing the amount of rare earth, and improving the effect of infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

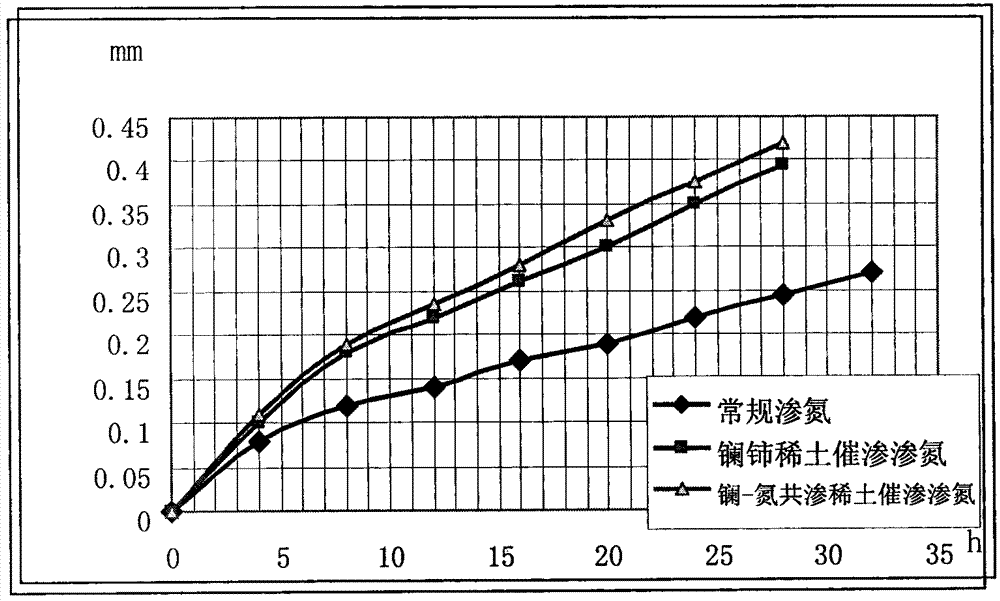

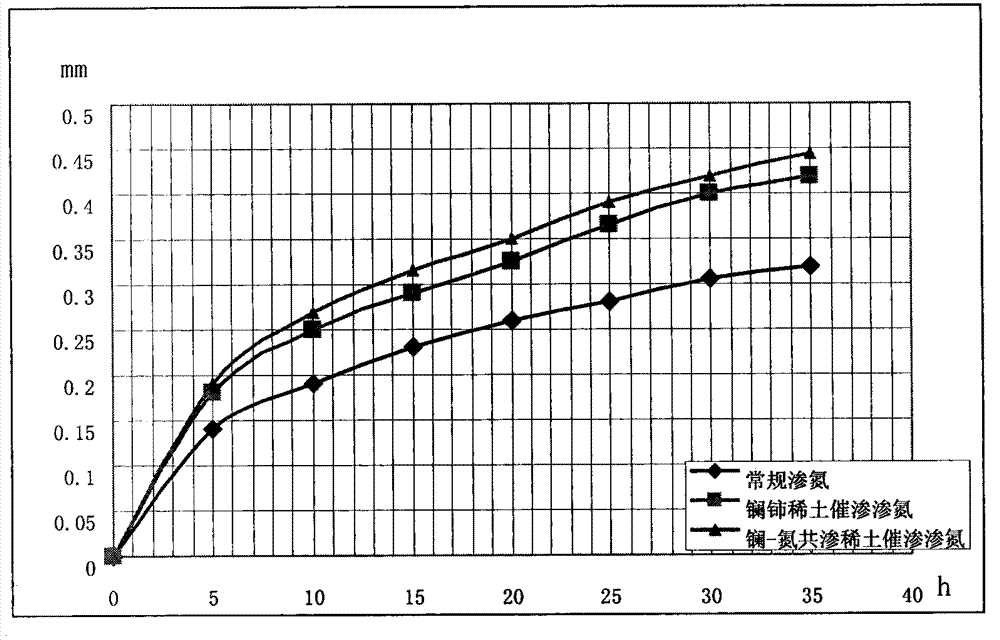

[0018] Embodiment 1: The lanthanum-nitridation rare earth infiltration accelerator of this embodiment is composed of the following components according to weight percentage: lanthanum chloride: 40-80%; ammonium chloride: 10-50%; dicyandiamide: 5-30% %; Urea: 5-30%. The rare earth is lanthanum chloride rare earth, and the rare earth components are: lanthanum (La): 90-99% (La 2 o 3 / Re 2 o 3 ), wherein the content of cerium (Ce) is less than 5% (CeO 2 / Re 2 o 3 ).

[0019] The solid rare earth penetrating agent used in comparison is lanthanum cerium rare earth penetrating agent, and its main components are: rare earth chloride: 40-80%; ammonium chloride: 10-50%; urea: 5-30%, wherein the rare earth is Lanthanum cerium rare earth chloride, the rare earth components are: containing lanthanum (La): 33% (La 2 o 3 / Re 2 o 3 ), containing cerium (Ce) 66% (CeO 2 / Re 2 o 3 ).

[0020] The conventional nitriding used in comparison does not add any rare earth infiltratin...

specific Embodiment approach 2

[0021] Specific implementation mode two: the present implementation mode realizes its object of the invention through the following technical solutions:

[0022] 1. Test conditions:

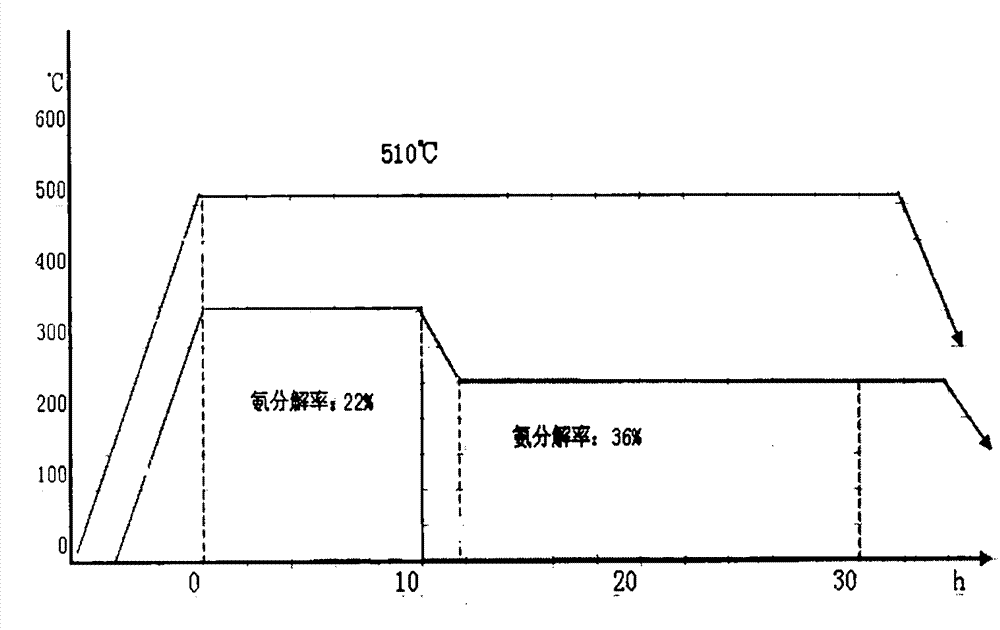

[0023] 1. Nitriding equipment: RN6-280-6 well type gas nitriding furnace.

[0024] 2. Basic process conditions: Ammonia flow rate: 2.3~2.6m 3 / h, furnace pressure: 120~180mm water column

[0025] 3. Test materials: 38CrMoAl steel test block; and 42CrMo steel test block are added during normal nitriding operation;

[0026] 4. The rare-earth osmotic agent is respectively: lanthanum rare-earth osmotic agent; the composition is: 40-80% of lanthanum chloride; 10-50% of ammonium chloride; 5-30% of dicyandiamide; 5-30% of urea. The rare earth is lanthanum chloride rare earth, containing lanthanum (La): 90% (La 2 o 3 / Re 2 o 3 ), wherein the content of cerium (Ce) is less than 5% (CeO 2 / Re 2 o 3 ).

[0027] Lanthanum cerium rare earth permeation agent: the composition is: rare earth chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com