Transparent heat mirror of solar photothermal conversion heat collector and manufacturing method of transparent heat mirror

A light-to-heat conversion and solar energy technology, applied in the direction of solar thermal power generation, solar thermal devices, chemical instruments and methods, etc., can solve the problem of loss of sunlight transmittance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Example 1 Solar light-to-heat conversion heat collector transparent thermal mirror and its preparation

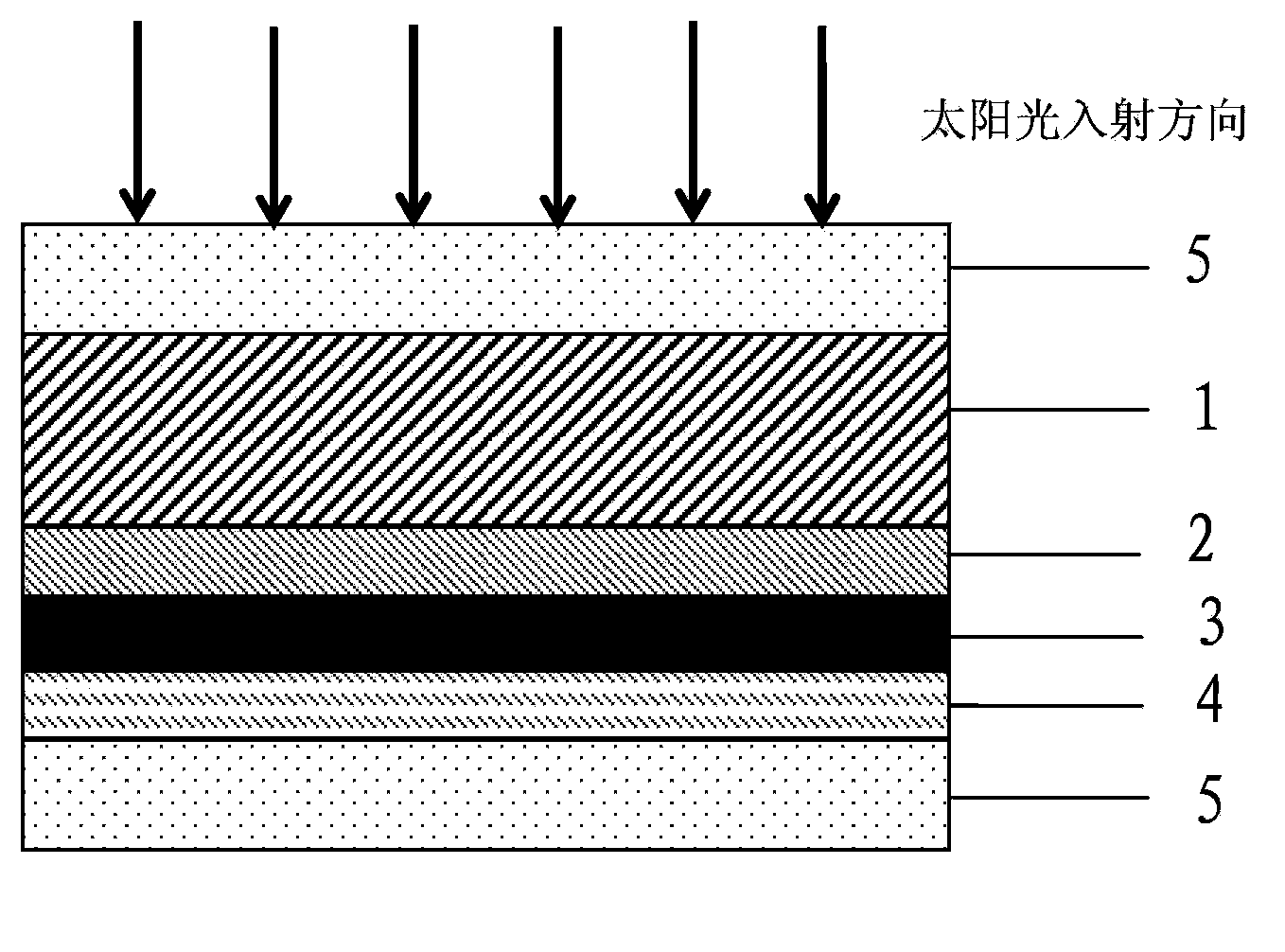

[0077] The membrane structure of this example is:

[0078] (where K is a multiple of 1 / 4 central wavelength λ=480nm, and d is the physical thickness of each layer of film) The preparation steps of the transparent hot mirror are described in detail below:

[0079] 1) Glass is 1mm borate low-iron glass (plane size: 300×300mm). The glass substrate processing method is the same as the aforementioned 1.1.

[0080] 2) D1 is the material A1 introduced in Section 2.1 2 o 3 , 81nm, the coating process is the same as 1.3; the substrate movement speed: 0.4m / min; the substrate moves back and forth 24 times.

[0081] 3) The ITO layer is 121nm, in A1 2 o 3 Deposit ITO on the layer, the coating process is the same as 1.2, the substrate movement speed: 0.4m / min; the substrate moves back and forth twice.

[0082] 4) D2 material is SiO 2 , 90nm, deposited SiO on the ITO la...

Embodiment 2

[0090] Example 2 Transparent thermal mirror of solar light-to-heat conversion collector and its preparation

[0091] In this example, the film structure transparent hot mirror is:

[0092]

[0093] (K is a multiple of 1 / 4 central wavelength λ=480nm, d is the physical thickness of each film) here:

[0094] D1 is the high refractive index material TiO introduced in Section 2.2 2 and low refractive index material SiO 2 Alternate, the number of times of alternation n=1; the materials of the remaining layers are the same as in Example 1), K and d are designed according to the above-mentioned values in this example.

[0095] In this example, steps 1), 3)-5) in the preparation are the same as in Example 1, except that step 2) has changed: TiO in step 2) 2 Deposited on a glass substrate, the coating process is the same as 1.4, the substrate movement rate: 0.4m / min; the substrate moves back and forth 3 times; SiO 2 TiO deposited on D1 2 On the layer, the coating process is th...

Embodiment 3

[0097] Example 3 Solar-light-to-heat conversion heat collector transparent thermal mirror and its preparation

[0098] In this example, the film structure transparent hot mirror is:

[0099]

[0100] (K is a multiple of 1 / 4 central wavelength λ=550nm, d is the physical thickness of each film) here:

[0101] D1 is the (high refractive index / low refractive index) n introduced in Section 2.2, n=2, where the high refractive index material is ITO, and the low refractive index material is SiO 2 All the other layer materials are identical with embodiment 1), K and d are by the above-mentioned design value of this example.

[0102] In this example, the method of processing the glass substrate in step 1) of the preparation is the same as that in Example 1.

[0103] In this example, step 2 in the preparation) prepares D1 (ITO / SiO 2 ) 2 In the magnetron sputtering coating process parameters, n is the stage of 1, when the ITO film with a thickness of about 21nm is prepared on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com