Microscopy characterization and evaluation method of homogeneity of carbon fibers

An evaluation method, carbon fiber technology, applied in the preparation of test samples, material analysis using radiation diffraction, etc., can solve the problems of lack of quantifiable operability of information, too macroscopic concepts, and inability to give qualitative information on structural changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

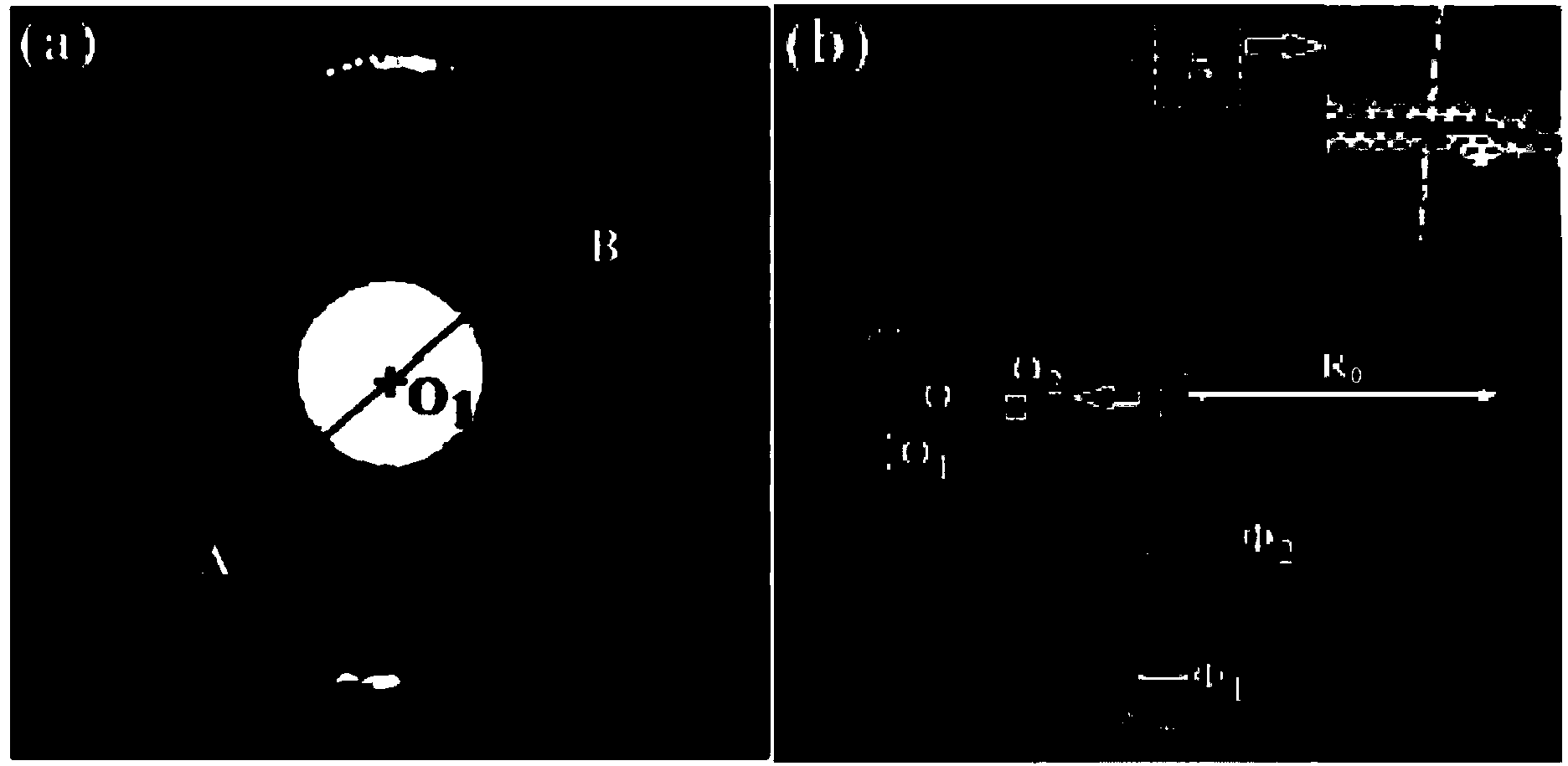

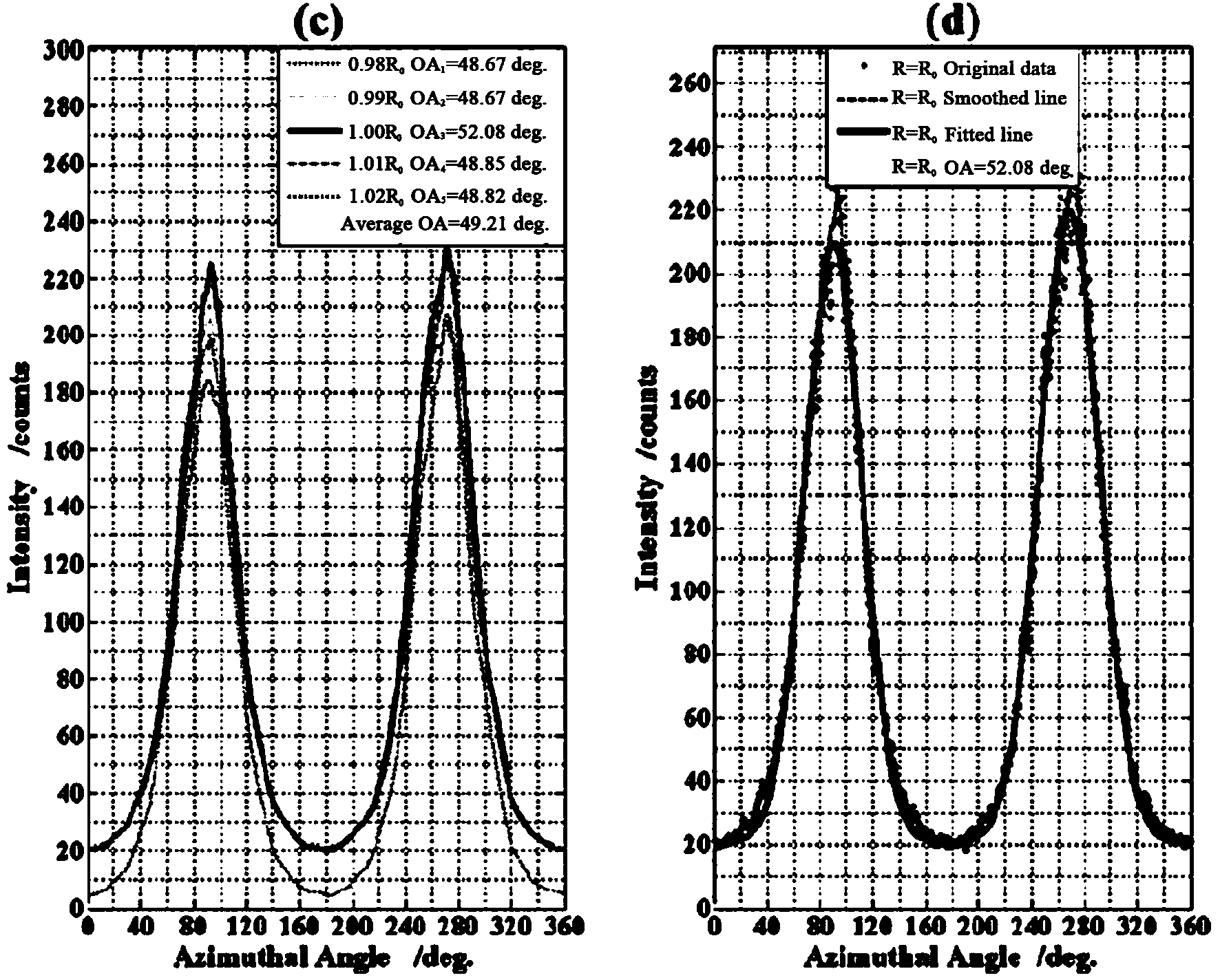

Method used

Image

Examples

Embodiment 1

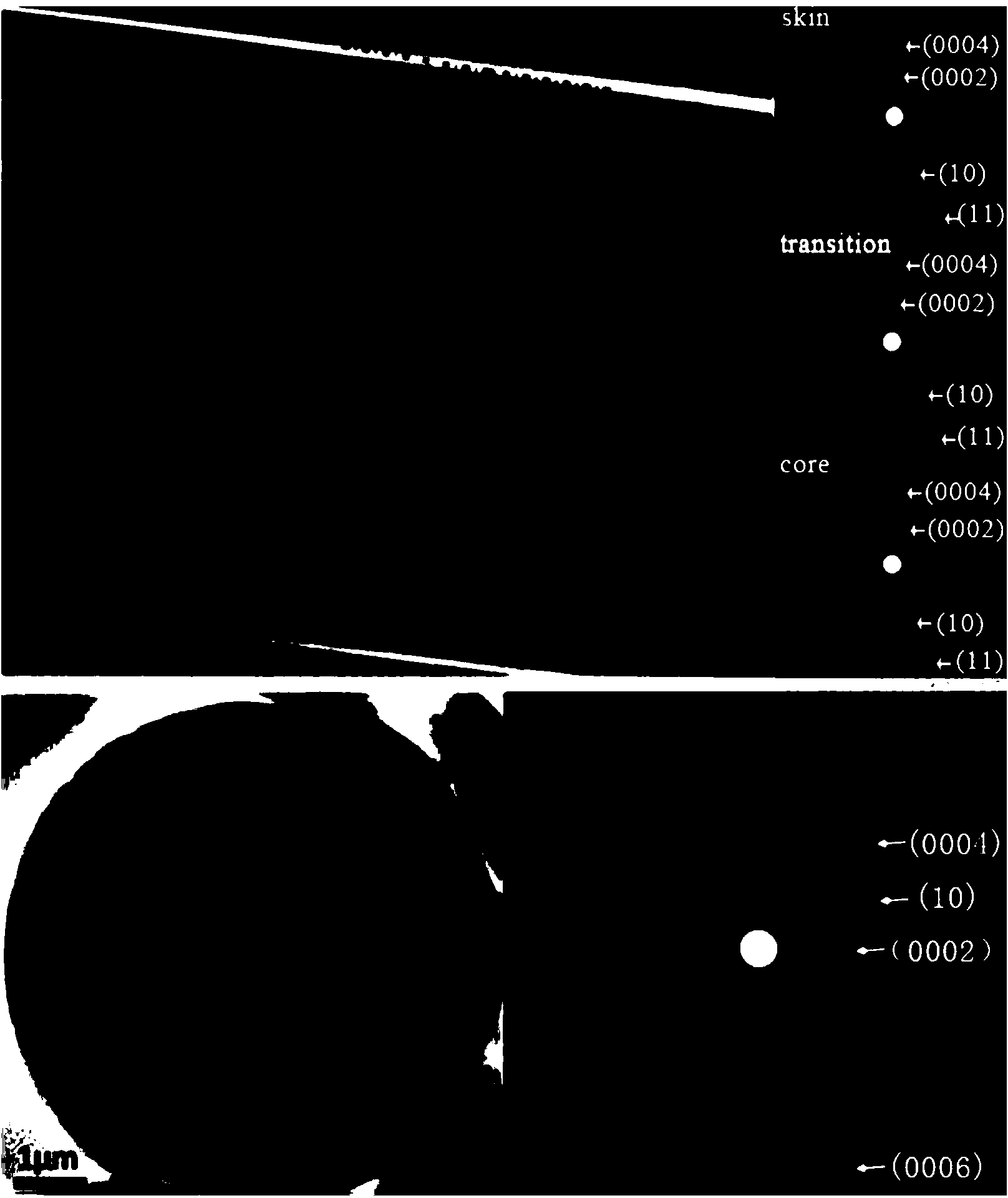

[0044] 1. T700S carbon fiber material sample preparation

[0045] When embedding and preparing thin-section samples, ensure that the fiber axis is placed horizontally. Using 3~6kV argon ions in high vacuum (10 -5 Pa) directly bombard the sample to obtain a thinner sample. During thinning, the angle between the incident argon ion beam and the surface of the sample is φ. Using the LKY-AB ion thinning instrument, first select the angle φ=20°. When the central area of the sample is slightly transparent during thinning , reduce the included angle φ to 13°, and then reduce it from 13° to 8°; the time of "sweeping" the sample surface is reduced from 20min to 10min to "clean" the surface of the sample to ensure that the fiber The uniformity of the thickness of the thin area in the diameter direction. In this experiment, the sample thickness at the data collection position is greater than 5nm and less than 50nm.

[0046] 2. Collect SAED spectrum

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com