Carbon nano tube electric conduction slurry and preparation method and application thereof

A technology of carbon nanotubes and conductive pastes, applied in the direction of nanotechnology, nanotechnology, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of affecting the conductivity of lithium-ion batteries, affecting the physical properties of carbon nanotubes, and agglomeration Settlement and other problems, to achieve the effect of easy implementation and large-scale popularization and application, low production cost, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

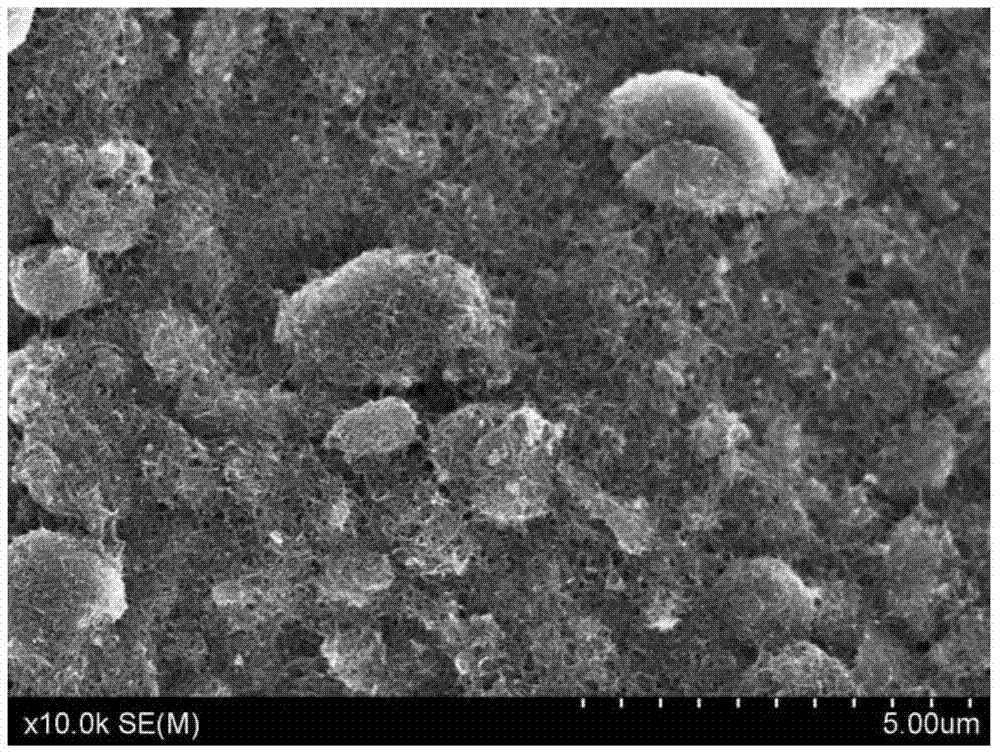

[0028] 500 g of carbon nanotube groups prepared from multi-walled carbon nanotubes, 100 g of polyvinylpyrrolidone and 9.4 kg of N-methylpyrrolidone were stirred and mixed for 5 minutes, and then ground for 20 minutes in a grinder with grinding media , wherein, the linear velocity of the grinding machine dispersing disc is 10 meters per second, and the grinding medium is a zirconium bead of 1mm, and after grinding, stable carbon nanotube conductive paste containing spherical carbon nanotube groups is obtained. In the present embodiment, the conductive The carbon nanotube group in the slurry is in the shape of an ellipsoid, and its scanning image is as follows figure 1 shown.

Embodiment 2

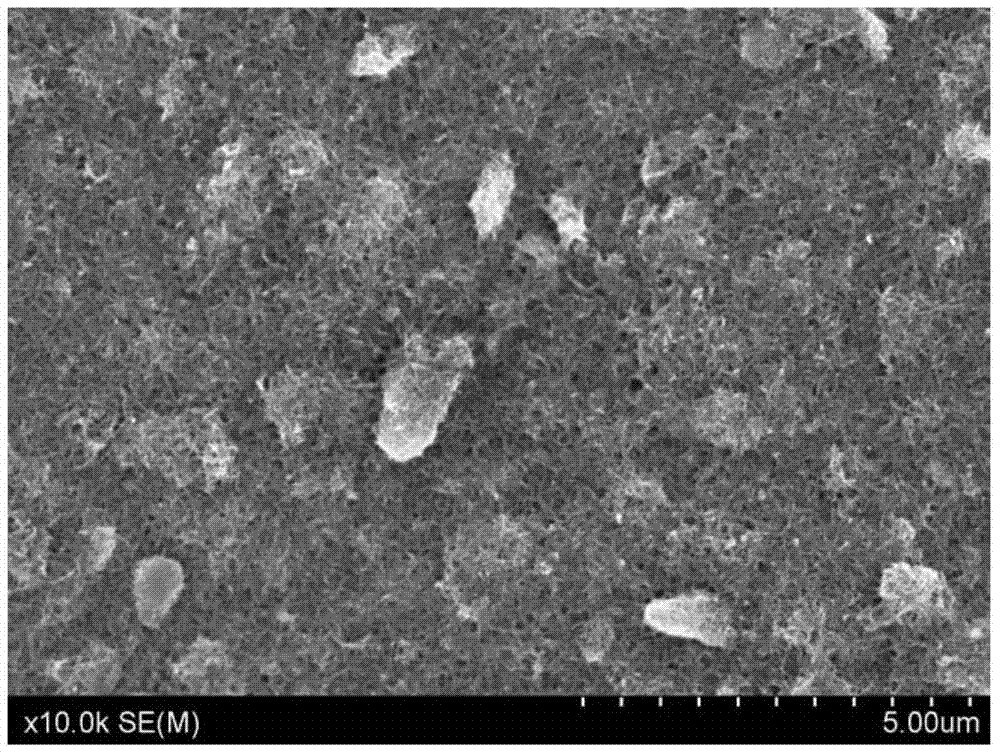

[0030] 500 g of carbon nanotube aggregates prepared from multi-walled carbon nanotubes, 100 g of polyvinylpyrrolidone, and 9.4 kg of N-methylpyrrolidone were stirred and mixed for 5 minutes, and then ground for 5 seconds in a media-free sand mill clock, wherein, the sand mill dispersing disc linear velocity is 50 m / s, obtains the stable carbon nanotube conductive paste containing spherical carbon nanotube groups, in the present embodiment, the carbon nanotube group in the conductive paste It is ellipsoidal, and its scanning image is as follows figure 2 shown.

Embodiment 3

[0032] 500 grams of multi-walled carbon nanotubes are used to prepare carbon nanotube aggregates, 50 grams of sodium carboxymethylcellulose and 9.45 kilograms of water and stir and mix for 5 minutes, then grind for 20 minutes in a grinder with grinding media, wherein, The linear speed of the dispersion disc of the grinder is 10 m / s, and the medium is a zirconium bead of 1 mm, so as to obtain a stable carbon nanotube conductive paste containing spherical carbon nanotube groups. In this embodiment, the carbon nanotube in the conductive paste The group is ellipsoidal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com