Method for preparing air cathode of microbial fuel cell by using petroleum cokes

An air cathode and fuel cell technology, applied in the direction of biochemical fuel cells, battery electrodes, electrical components, etc., can solve the problem of high price of activated carbon, achieve the effects of reducing production costs, realizing resource utilization, and realizing full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

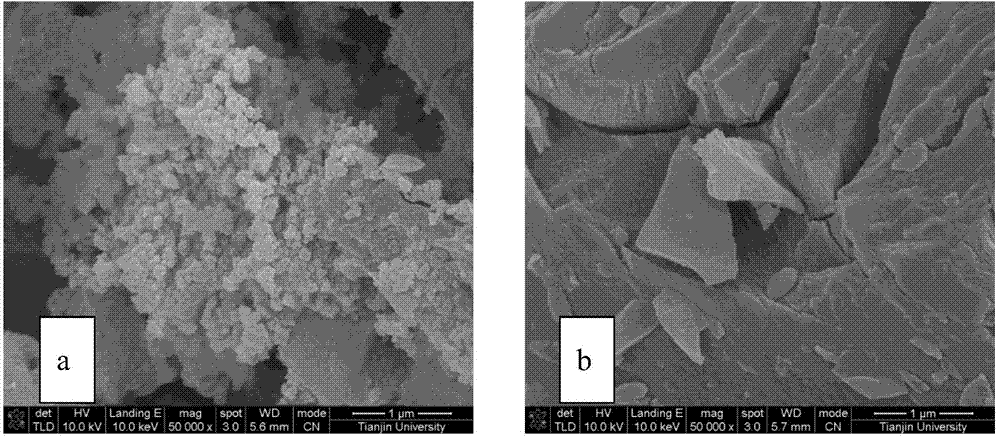

Image

Examples

Embodiment 1

[0032] The preparation method of the petroleum coke activator air cathode in the present invention comprises the steps:

[0033] Activation of Petroleum Coke

[0034] The petroleum coke solid is put into a ball mill and ground to a particle size below 200 microns, which is used as the raw material for the next step of activation. Mix a certain amount of petroleum coke powder and KOH in a weight ratio of 4:1, place them in a mortar and continue grinding, so that the two can be evenly mixed. The mixed powder is placed in a porcelain boat, placed in a tube furnace, and activated under the protection of nitrogen.

[0035] Activation process, including initial activation and final activation. The initial activation is to raise the temperature of the tube furnace to 300°C at a rate of 3°C / min and keep it there for one hour. The final activation is based on the preliminary activation, the temperature of the tube furnace is raised to 800°C at a rate of 5°C / min and kept for 1 hour. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com