Blisk single-face/double-face laser shock peening light path system

A technology of laser shock strengthening and optical path system, which is applied in laser welding equipment, mechanical equipment, turbines, etc., can solve the problems of low laser shock strengthening efficiency, low repetition frequency, and limited single pulse energy, and achieve fast and effective integrity, In terms of use, the effect of convenient path planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

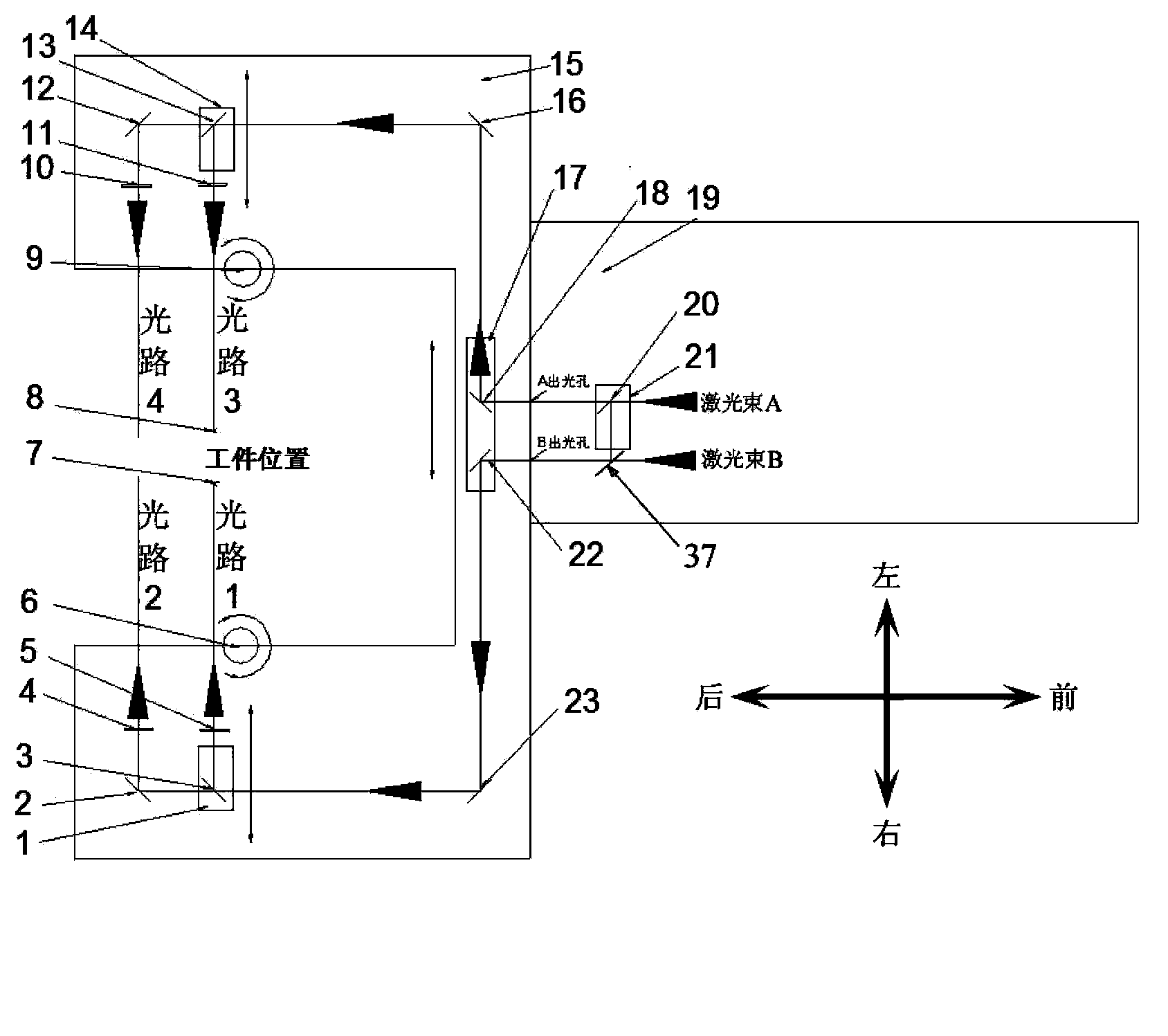

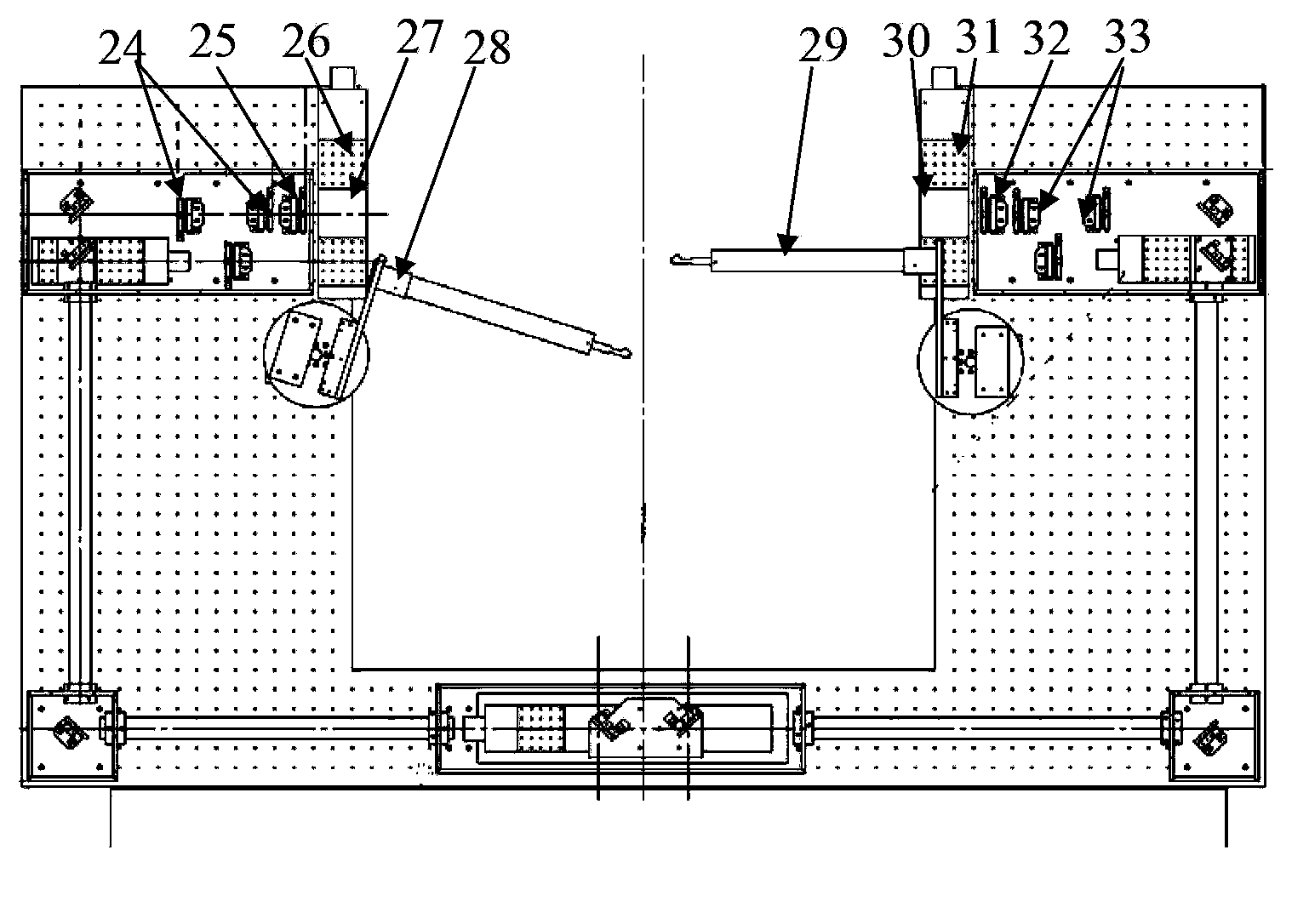

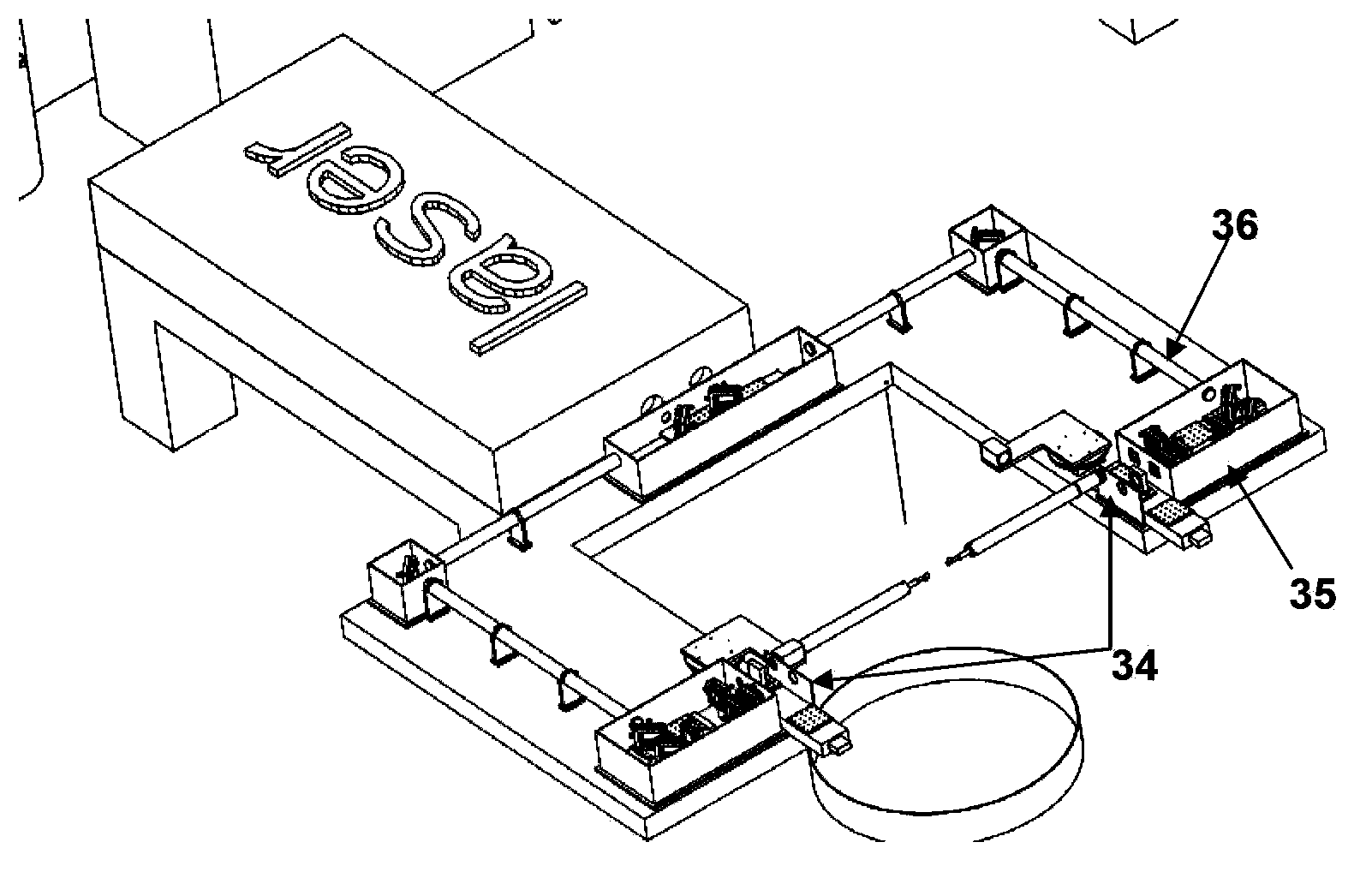

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 1-5 As shown, the single / double-sided laser shock strengthening optical path system of the whole blisk of the present invention includes: the optical path one and optical path two switching slide table 1 installed on the optical platform 15, the optical path three and optical path four switching slide table 14 and the light outlet sliding table 17; CNC sliding table 21 installed inside the laser 19 for optical path switching; optical path three turntable 9 and optical path one turntable 6 installed on the optical platform 15; optical path three and optical path four calibration slides installed on the optical platform 15 26 and optical path one and optical path two calibration slide table 31; optical path two reflectors 2, optical path four reflectors 12, reflector A16 and reflector B23 installed on the optical platform 15; optical path...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com