Novel partial-nitrosation anaerobic ammoxidation integrated reactor

An anammox and reactor technology, applied in anaerobic digestion treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of anammox bacteria denitrification effect, reoxygenation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and examples.

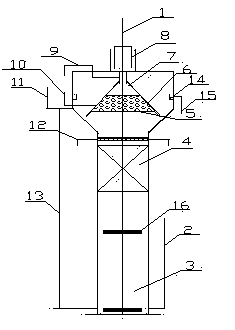

[0020] The invention proposes a novel partial nitrosation integrated anaerobic ammonium oxidation reactor. refer to figure 1 As shown, a new type of partially nitrosated anammox reactor includes a main reaction zone, an upper three-phase separator 6 and an airlift chamber 11. The inside of the main reaction zone is a sludge fluidization zone 3, The middle biofilm area 4, the upper biofilm area 5, the outside of the main reaction area are the bottom water inlet 2, the air inlet 12, and the upper water outlet 14 from bottom to top; the interior of the three-phase separator 6 area includes from bottom to top The biofilm 5 area and the gas collection chamber 7, the outside of the three-phase separator 6 area is a sedimentation area; the reactor sludge fluidization area is provided with a driving device 1; the outside of the reactor body is provided with an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com