A physical and chemical treatment agent for industrial wastewater and its application

A technology of industrial wastewater and treatment agent, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of poor broad-spectrum treatment, waste of water resources, excessive chroma, etc. , to achieve high application value and improve the effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

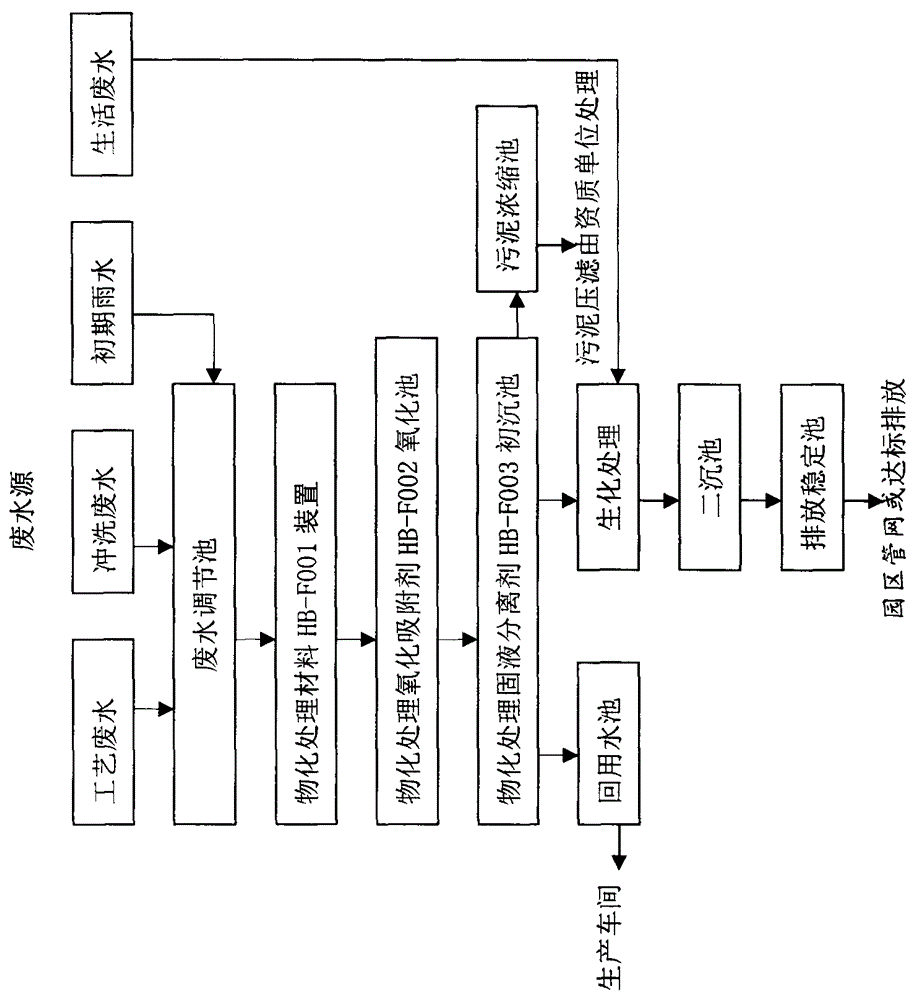

[0025] Technical thinking of the present invention is:

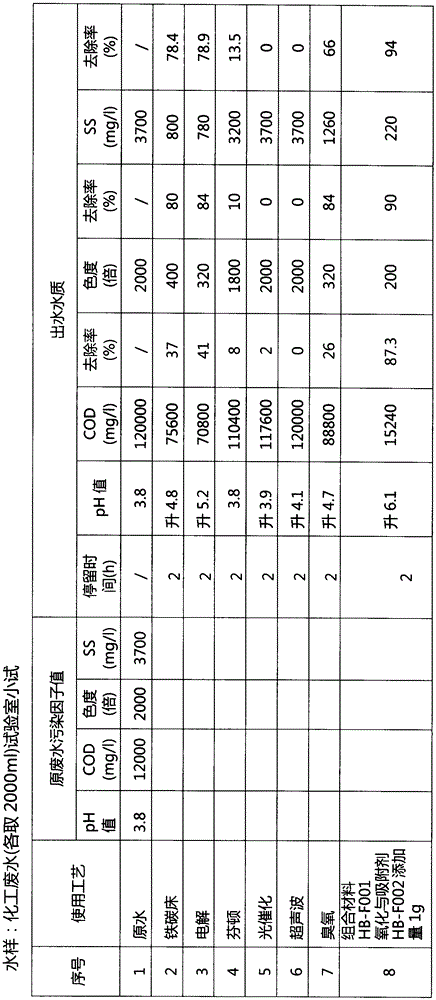

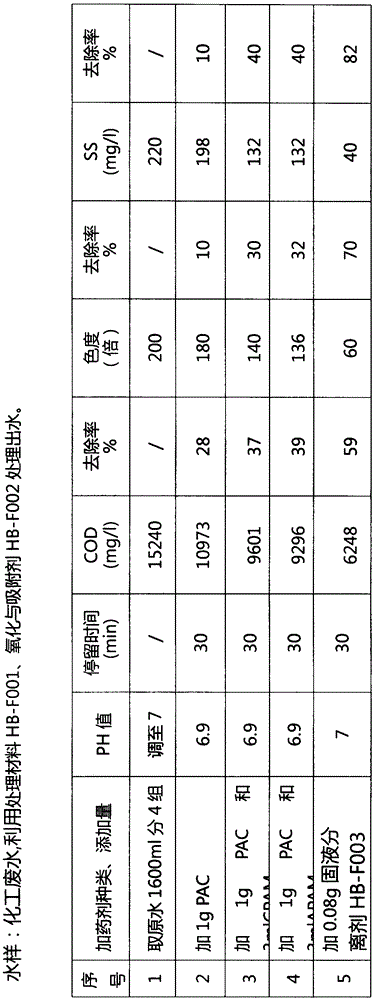

[0026] Provide application technology, physical and chemical treatment materials HB-F001, physical and chemical treatment oxidation and adsorbent HB-F002, physical and chemical treatment solid-liquid separation agent HB-F003; mainly overcome the low efficiency of subsequent treatment of iron-carbon bed compaction, large power consumption of electrolysis and many consumables A lot of solid waste, repeated adjustment of pH value in Fenton treatment produces a large amount of salt, causing secondary pollution, limited application range of photocatalysis and ultrasonic waves, high power consumption of ozone, large investment and unstable ozone generation, and the problem of unstable treatment effect has been solved. Wet oxidation method Solve the problem of high cost and safety, solve the general problem of flocculation of industrial wastewater by conventional flocculants, solve the problem of reusing 50% of industrial wastew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com