Metal-organic coordination polymer thermoelectric material, preparation method and application thereof

A thermoelectric material and organic technology, applied in the field of metal organic coordination polymer thermoelectric materials and their preparation, to achieve the effects of simple process, easy preparation and improved thermoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, copper-7,7,8, the preparation of 8-tetracyano p-quinone

[0033] In an argon atmosphere, dissolve 0.510g (2.5mmol) of 7,7,8,8-tetracyano-p-dimethylbenzoquinone in anhydrous acetonitrile, heat to reflux for about 20min until completely dissolved; use solid sample Add 0.476g (2.5mmol) cuprous iodide dispersed in acetonitrile suspension, reflux for 1min; filter, wash the obtained microcrystalline solid with a large amount of acetonitrile in turn, dry in a vacuum oven at 50oC to obtain copper-7 , 7,8,8-Tetracyano-p-dimethylbenzoquinone crystallite sample.

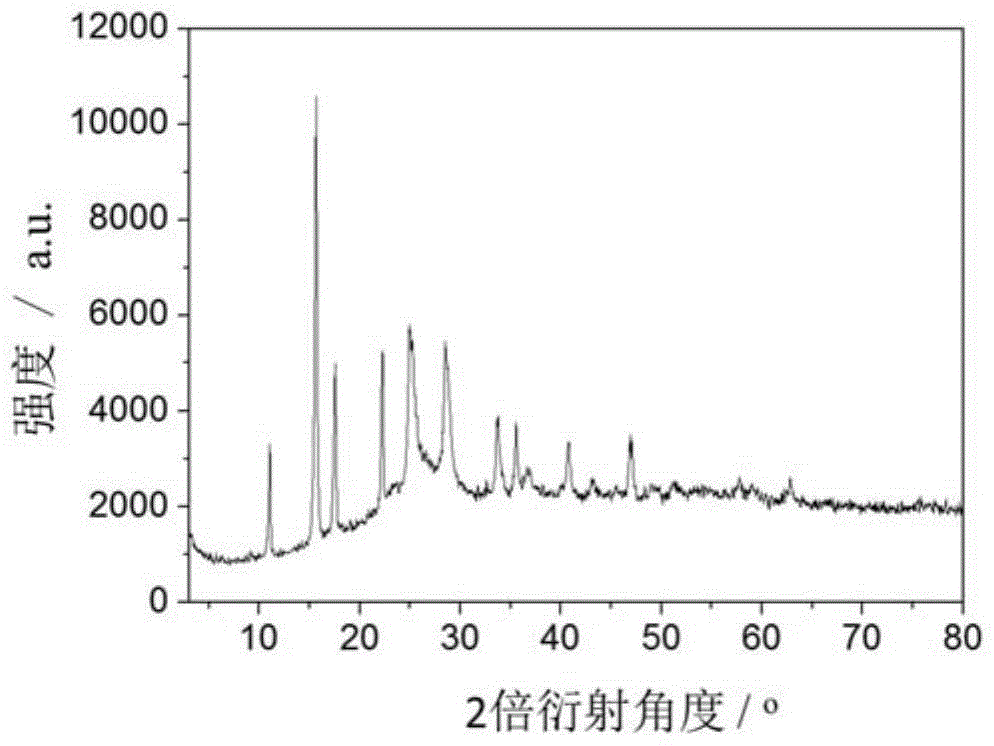

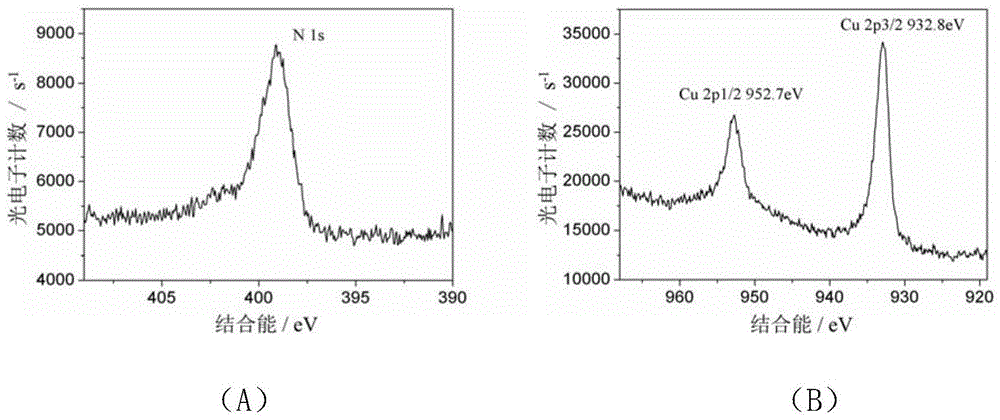

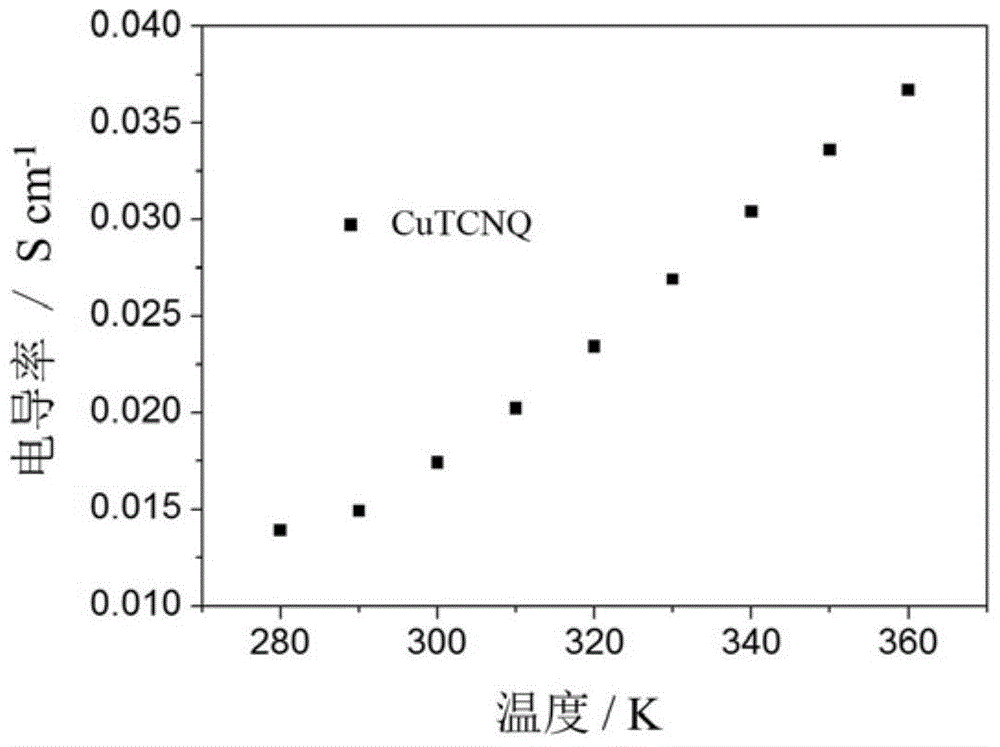

[0034] The X-ray diffraction spectrum of the copper-7,7,8,8-tetracyano-p-dimethylbenzoquinone crystallite sample prepared in this embodiment is as follows figure 1 As shown, its X-ray photoelectron spectrum is shown as figure 2 As shown, among them, figure 2 (A) is the N1s spectrum of copper-7,7,8,8-tetracyano-4-quinone microcrystalline sample, figure 2 (B) is the Cu2pXPS spectrum of copper-7,7,8,8-t...

Embodiment 2

[0036] Example 2. Copper-7,7,8,8-tetracyano-p-quinone doped with 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodimethyl-p-benzoquinone Preparation of Dimethylbenzoquinone

[0037]In an argon atmosphere, weigh 3.5 mg, 0.0125 mmol 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodimethyl-p-benzoquinone (purchased from Acros Reagent Company) and 0.510 g. 2.5mmol 7,7,8,8-tetracyano-p-methylbenzoquinone (molar ratio 1:200), dissolved in 100ml of anhydrous acetonitrile, heated to reflux for about 20min until completely dissolved; use a solid sampler Add 0.4785g, 2.5125mmol of cuprous iodide dispersed in acetonitrile suspension, reflux for 10s; rapidly heat filter, wash the obtained microcrystalline solid with a large amount of acetonitrile in turn, and dry it in a vacuum oven at 50oC to obtain the doped A microcrystalline sample of copper-7,7,8,8-tetracyano-p-dimethylbenzoquinone.

[0038] Follow the same steps above, and change the dosage of 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodimethyl-p-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com