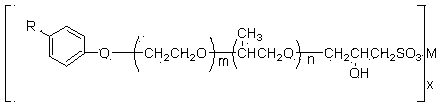

Phenol ether sulfonate oil-based emulsifier and preparation method thereof

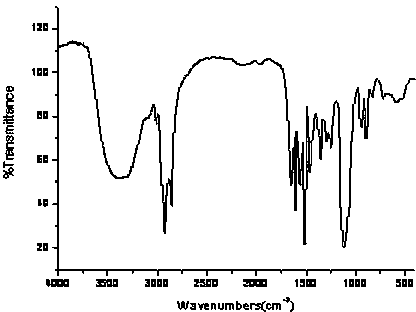

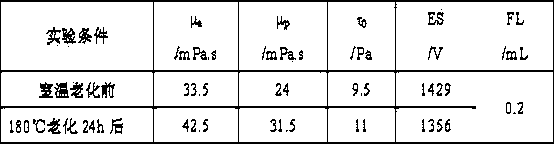

A technology of phenol ether sulfonate, phenol polyoxyethylene polyoxypropylene ether hydroxypropane sulfonic acid, applied in sulfonate preparation, chemical instruments and methods, organic chemistry and other directions, can solve the problem of few emulsifiers and poor emulsification performance , salt intolerance and other problems, to achieve the effect of excellent temperature resistance, good emulsion stability and small filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (a) Synthesis of nonylphenol polyoxyethylene polyoxypropylene ether (m=2, n=15)

[0030] Add 220 grams (1 mole) of nonylphenol and 5.6 grams of calcium oxide catalyst to a reactor equipped with a condensing device, a stirring device and a gas disperser. When heating to 135°C while blowing nitrogen, add 20 grams of water and stir to react. 1 hour. After the water is removed, the temperature is lowered to 80°C, and the theoretical amount of sulfuric acid (20wt%) neutralizing the catalyst is slowly added dropwise to obtain a high activity and high selectivity composite calcium oxide alkoxylation catalyst reaction liquid system. Heat the temperature to 80~90℃, turn on the vacuum system, dehydrate under high vacuum for 2 hours, then purge with nitrogen 3~4 times, adjust the reaction temperature of the system to 150℃ and slowly pour into 88 grams (2 moles) of epoxy Ethane, controlled pressure≤0.40MPa, after the ethylene oxide reaction is over, 870 grams (15 moles) of propylene ...

Embodiment 2

[0037] (a) Synthesis of octylphenol polyoxyethylene polyoxypropylene ether (m=1, n=30)

[0038] Add 206 grams (1 mole) of octylphenol and 10.3 grams of calcium oxide catalyst to a reactor equipped with a condensing device, a stirring device and a gas disperser, and the same as [Example 1] to obtain a composite type with high activity and high selectivity Calcium oxide alkoxylation catalyst reaction liquid system, heat the system temperature to 80~90℃, turn on the vacuum system, dehydrate under high vacuum for 2 hours, then purge with nitrogen 3 to 4 times, adjust the system reaction temperature to 160 Slowly pass in 44 grams (1 mole) of ethylene oxide at ℃, and control the pressure ≤ 0.60 MPa. After the ethylene oxide reaction is over, slowly pass in 1740 grams (30 moles) of propylene oxide at 160°C to control the pressure ≤0.60MPa. After the reaction, the system was purged with nitrogen, and after cooling, it was neutralized and dehydrated to obtain 1920.4 g of octylphenol poly...

Embodiment 3

[0043] (a) Synthesis of dodecylphenol polyoxyethylene polyoxypropylene ether (m=4, n=15)

[0044] Add 262 grams (1 mole) of dodecylphenol and 11.8 grams of calcium oxide catalyst to a reactor equipped with a condensing device, a stirring device and a gas disperser, and the same as [Example 1] to obtain a highly active and selective Compound type calcium oxide alkoxylation catalyst reaction liquid system, heat the system temperature to 80~90℃, turn on the vacuum system, dehydrate under high vacuum for 2 hours, then purge with nitrogen 3~4 times to adjust the reaction temperature of the system Slowly feed 176 grams (4 moles) of ethylene oxide at 140°C, and control the pressure to ≤0.50MPa. After the ethylene oxide reaction is over, slowly feed 870 grams (15 moles) of propylene oxide at 140°C. Control pressure ≤0.50MPa. After the reaction, the system was purged with nitrogen, and after cooling, it was neutralized and dehydrated to obtain 1240.0 grams of dodecylphenol polyoxyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com