Polyurethane rubber texture coating and preparation method thereof

A polyurethane rubber and texture coating technology, applied in the coating and other directions, can solve the problems that the exterior wall real stone paint is not environmentally friendly, the color is uneven, and the construction is easy to flower, and it is suitable for large-scale industrial production and short drying time. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

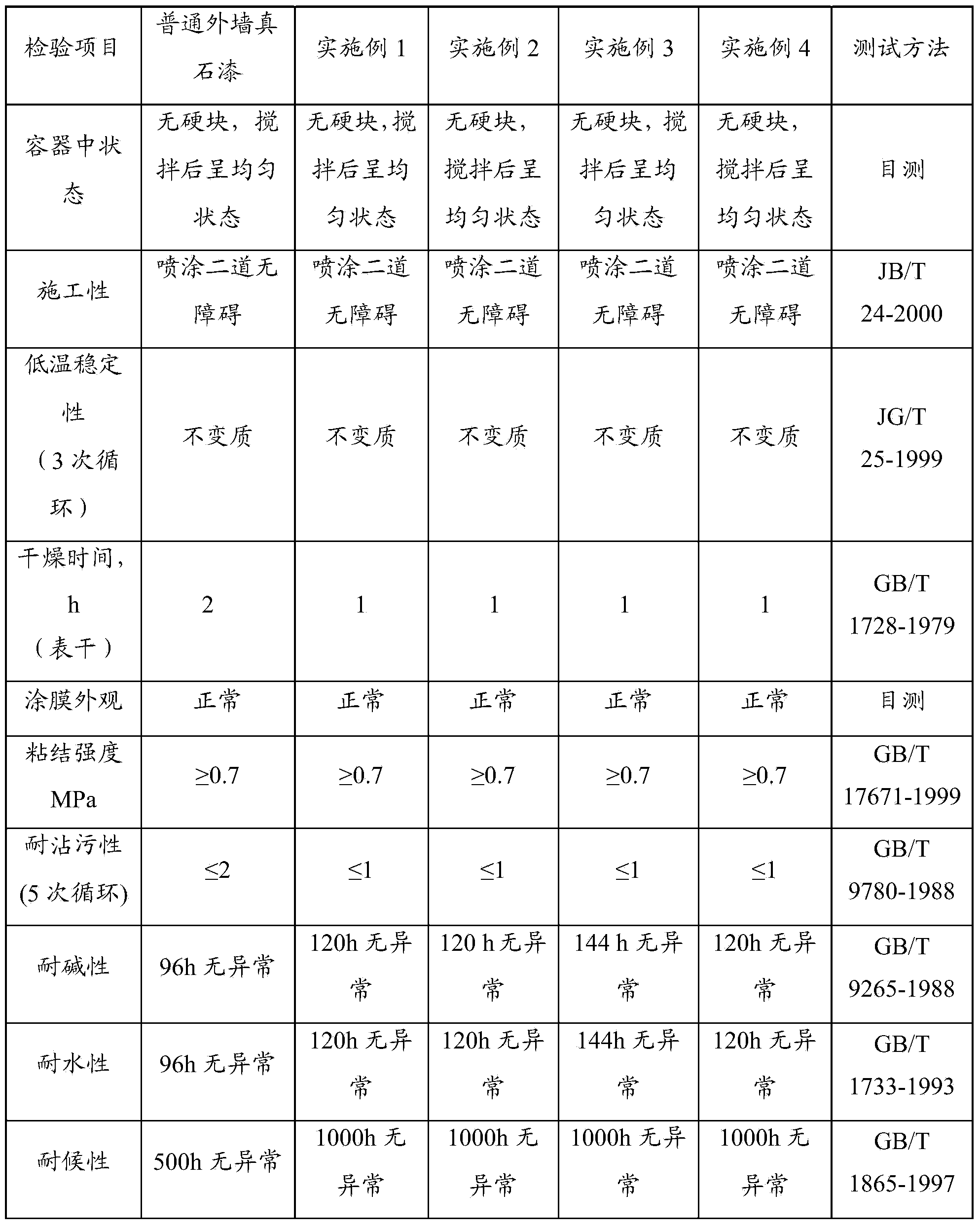

[0038] The raw material formulation (wt%) of the polyurethane rubber texture coating is shown in Table 1 below.

[0039] The raw material formula (wt%) of the polyurethane rubber texture coating of table 1 embodiment 1

[0040] Silicone acrylic emulsion TD-1

26.5%

Thickener HS-30000 Cellulose

0.2%

Neutralizer AMP-95

0.5%

0.1%

Preservative MBS

0.2%

Thickener 612

0.3%

Coalescent Texanol

1.2%

1.0%

EPDM rubber color particles

60.0%

Deionized water

10%

[0041] The preparation method of polyurethane rubber texture paint, it may further comprise the steps:

[0042] According to the above formula, the above-mentioned component neutralizer, the silicone defoamer accounting for 0.1% of the above-mentioned component silicone defoamer mass, the preservative accounting for 0.2% of the above-mentioned component preserva...

Embodiment 2

[0044] The raw material formulation (wt%) of the polyurethane rubber texture coating is shown in Table 2 below.

[0045] The raw material formula (wt%) of the polyurethane rubber texture coating of table 2 embodiment 2

[0046] Silicone acrylic emulsion KD96

28%

[0047] Thickener HS-30000 Cellulose

0.15%

Neutralizer AMP-95

0.3%

Silicone defoamer A-10

0.2%

Preservative MBS

0.3%

Thickener 612

0.4%

Coalescent Texanol

1.5%

antifreeze glycol

1.5%

EPDM rubber color particles

62.1%

Deionized water

5.55%

[0048] The preparation method of polyurethane rubber texture paint, it may further comprise the steps:

[0049]According to the above formula, the above-mentioned component neutralizer, the silicone defoamer accounting for 0.3% of the above-mentioned component silicone defoamer mass, the preservative accounting for 0.3% of the above-mentioned component p...

Embodiment 3

[0051] The raw material formulation (wt%) of the polyurethane rubber texture coating is shown in Table 3 below.

[0052] The raw material formula (wt%) of the polyurethane rubber texture coating of table 3 embodiment 3

[0053] Silicone acrylic emulsion RS-996AD

30.0%

Thickener HS-30000 Cellulose

0.3%

Neutralizer AMP-95

0.1%

Silicone defoamer SN-154

0.1%

Preservative MBS

0.2%

Thickener 612

0.5%

Coalescent Texanol

1.2%

1.0%

EPDM rubber color particles

65%

Deionized water

1.6%

[0054] The preparation method of polyurethane rubber texture paint, it may further comprise the steps:

[0055] According to the above formula, the above-mentioned component neutralizer, the silicone defoamer accounting for 0.1% of the above-mentioned component silicone defoamer mass, the preservative accounting for 0.2% of the above-mentioned component prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com