Long-acting low-temperature phase-change cool-storage material, and preparation method thereof

A technology of low-temperature phase change and cold storage materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of inconvenient use, supercooling phenomenon, low latent heat value of phase change, etc., and achieve wide solidification temperature range, large phase The effect of variable latent heat and long-term cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

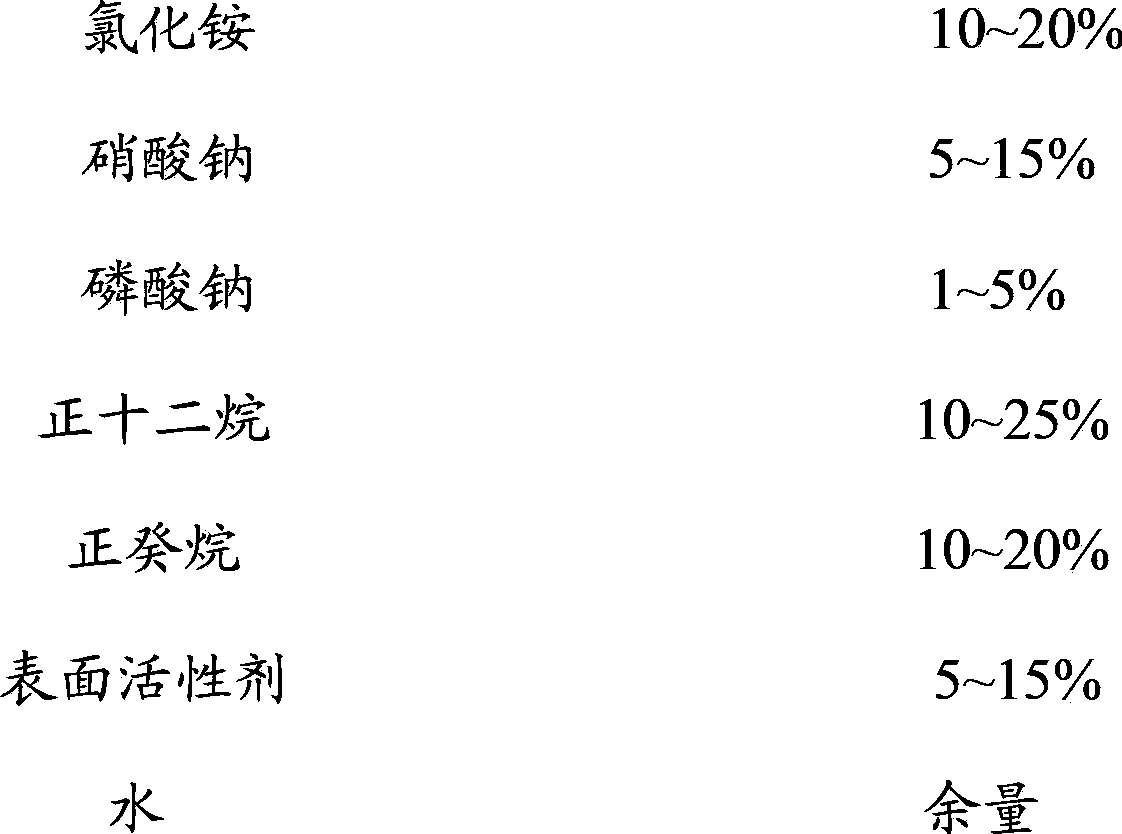

Method used

Image

Examples

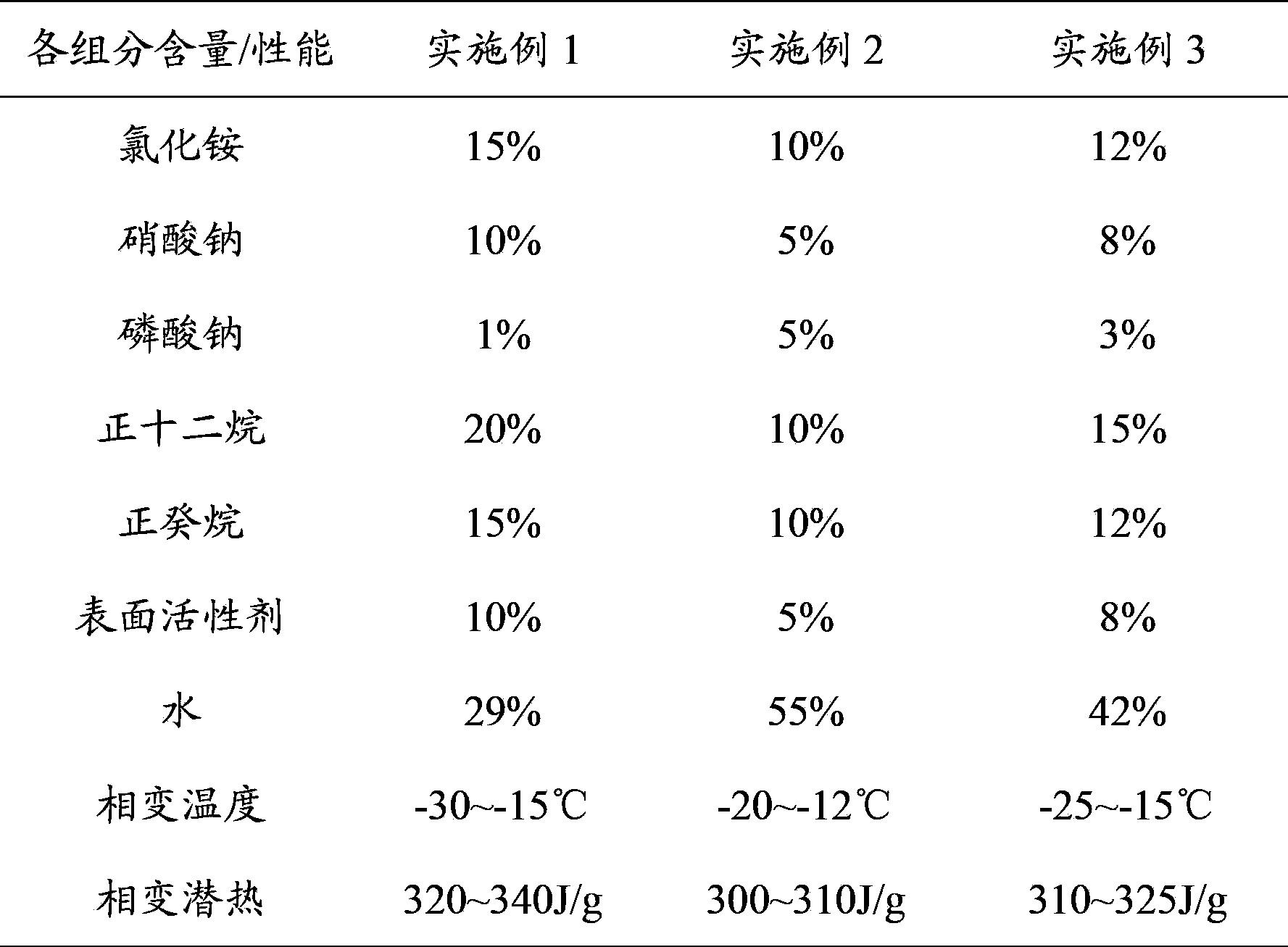

Embodiment 1

[0018] Under normal temperature and pressure, ammonium chloride, sodium nitrate, and sodium phosphate were dissolved in water according to the components specified in Table 1, and stirred at 5000r / min for 30 minutes; Sodium dialkylbenzenesulfonate was mixed and stirred at 5000r / min for 1 hour; then the aqueous and organic phases obtained in the above two steps were mixed and stirred at 5000r / min for 2 hours. Then the phase change temperature and latent heat of phase change of the obtained phase change cold storage material were tested, and the test results are listed in Table 1.

[0019] The present invention also carried out a further experiment on the phase-change cold storage material obtained according to the above ratio, using a commercially available common 26L incubator, and the insulation layer was polyurethane foam with a thickness of 2cm. At a constant room temperature of 18°C, 5kg of the phase-change cold storage material obtained according to the above proportions ...

Embodiment 2

[0021] Repeat the method of Example 1 with the content of each component specified in Table 1, but replace sodium dodecylbenzenesulfonate with Span 80 (Sorbitan monooleate), and the test results are shown in Table 1.

Embodiment 3

[0023] Repeat the method of Example 1 according to the content of each component specified in Table 1, but replace dodecane with a mixture of Tween 80 (polyoxyethylene sorbitan monooleate) and lecithin in a weight ratio of 1:1 Sodium phenyl sulfonate, the test results are listed in Table 1.

[0024] Table 1

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com