Method for producing L-lactic acid by using green sweet corn

A technology of tender sweet corn and lactic acid, which is applied in the field of lactic acid production, can solve the problems of difficult decolorization process and high production cost, and achieve the effects of environmental protection, reduced dosage, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] With 52°C heat-resistant Lactobacillus as the strain, the fermentation medium formula is: tender sweet corn 110g / L, yeast extract 1g / L, CaCO 3 60g / L, pH natural. CaCO 3 Sterilize separately at 121°C for 30 minutes.

[0032] After pulping tender sweet corn, add yeast extract, sterilize at 115°C for 10 minutes, cool to 52°C, and press 12U / g 嫩甜玉米 Add α-amylase, 200U / g 嫩甜玉米 Add glucoamylase, and add calcium chloride to a final concentration of 0.03%, then sterilized CaCO 3 Transfer to fermenter.

[0033] ① After the fermentation medium is sterilized and cooled, no acid cellulase is added.

[0034] ②After the fermentation medium is sterilized and cooled, add 50U / g 嫩甜玉米外壳 Add acid cellulase.

[0035] Add 0.2% Lactobacillus seed solution, 52°C, 100r / min, anaerobic fermentation for 50h. After the fermentation, the L-lactic acid content in the fermentation broth was measured according to GBT23528-2009, and the results are shown in Table 1.

[0036] Table 1

[0037] ...

Embodiment 2

[0039] With 52°C heat-resistant Lactobacillus as the strain, the fermentation medium formula is:

[0040] ① Corn starch 140g / L, corn steep liquor 1.6g / L, yeast extract 3g / L, CaCO 3 80g / L, pH natural. CaCO 3 Sterilize separately at 121°C for 30 minutes.

[0041] After pulping tender sweet corn, add yeast extract, sterilize at 115°C for 10 minutes, cool to 52°C, and press 16U / g 玉米淀粉 Add α-amylase, 300U / g 玉米淀粉 Add glucoamylase, and add calcium chloride to a final concentration of 0.05%, then sterilized CaCO 3 Transfer to fermenter.

[0042] ② Tender sweet corn 140g / L, yeast extract 3g / L, CaCO 3 80g / L, pH natural. CaCO 3 Sterilize separately at 121°C for 30 minutes.

[0043] After pulping tender sweet corn, add yeast extract, sterilize at 115°C for 10 minutes, cool to 52°C, and press 16U / g 嫩甜玉米 Add α-amylase, 300U / g 嫩甜玉米 Add glucoamylase, 60U / g 嫩甜玉米外壳 Add acid cellulase, and add calcium chloride to a final concentration of 0.05%, then sterilized CaCO 3 Transfer to fer...

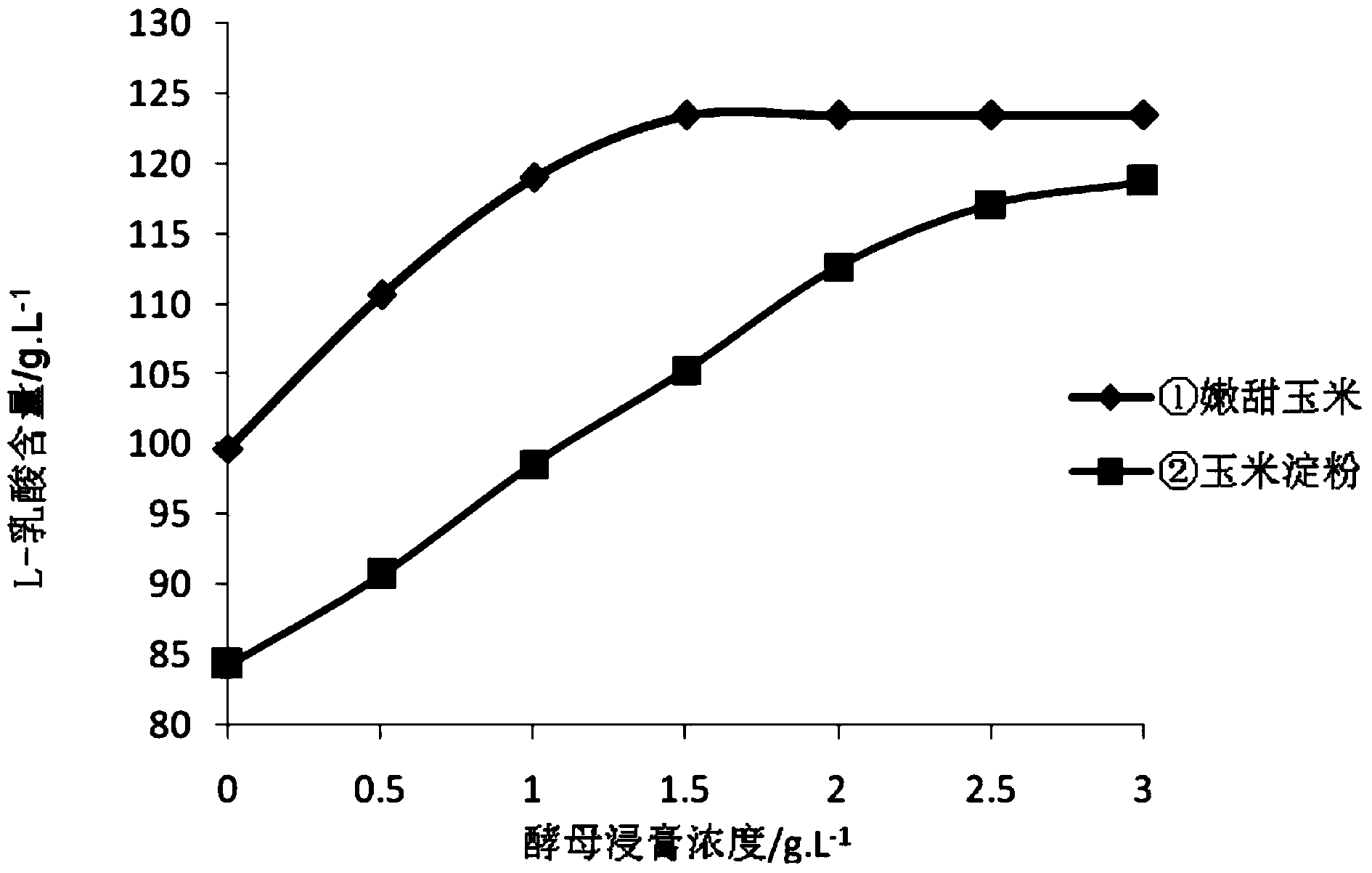

Embodiment 3

[0051] With 52°C heat-resistant Lactobacillus as the strain, the fermentation medium formula is:

[0052] ① Corn starch 140g / L, corn steep liquor 1.6g / L, yeast extract 0, 0.5, 1, 1.5, 2, 2.5, 3g / L, CaCO 3 80g / L, pH natural. CaCO 3 Sterilize separately at 121°C for 30 minutes.

[0053] After pulping tender sweet corn, add yeast extract, sterilize at 115°C for 10 minutes, cool to 52°C, and press 16U / g 玉米淀粉 Add α-amylase, 300U / g 玉米淀粉 Add glucoamylase, and add calcium chloride to a final concentration of 0.05%, then sterilized CaCO 3 Transfer to fermenter.

[0054] ② Tender sweet corn 140g / L, CaCO 3 80g / L, natural pH, yeast extract 0, 0.5, 1, 1.5, 2, 2.5, 3g / L. CaCO 3 Sterilize separately at 121°C for 30 minutes.

[0055] After pulping tender sweet corn, add yeast extract, sterilize at 115°C for 10 minutes, cool to 52°C, and press 16U / g 嫩甜玉米 Add α-amylase, 300U / g 嫩甜玉米 Add glucoamylase, 60U / g 嫩甜玉米外壳 Add acid cellulase, and add calcium chloride to a final concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com