Method for preparing fatty acid colloid solution applied to crypthecodinium cohnii for producing docosahexaenoic acid

A technology of docosahexaenoic acid and colloidal solution, which is applied in the field of preparation of fatty acid colloidal solution by artificial emulsification, can solve problems such as innovative applications that have not been published or reported, achieve flexible addition methods, improve utilization, The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

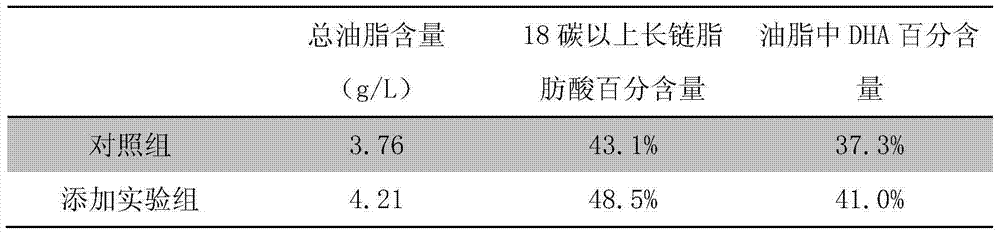

[0019] Emulsified palmitic acid as fermentation additive

[0020] Palmitic acid (molecular formula: C 16 h 32 o 2 ) at room temperature is a white scaly solid with pearly luster, insoluble in water, directly added as a substrate is not easily absorbed by microalgae, and is also a precursor for the synthesis of docosahexaenoic acid (DHA).

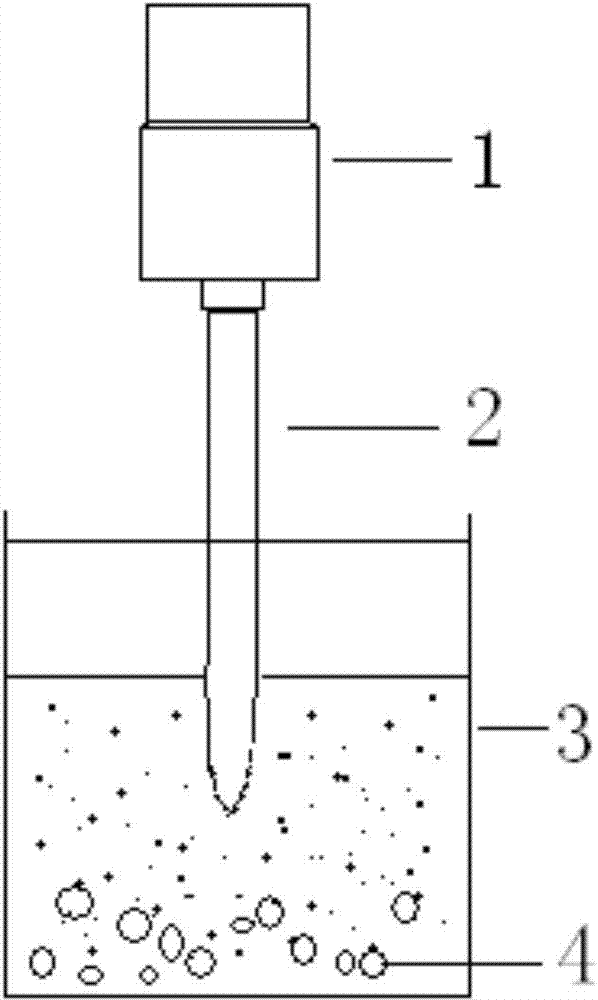

[0021] Take 500 milliliters of water, add 25 grams of solid palmitic acid, and then add 8 milliliters of Tween80 reagent. Low concentration of additives will not achieve emulsification effect, and high concentration will also cause instability of the colloidal system. Slowly heat to 90°C, use a general-purpose ultrasonic generator device, the diameter of the horn is about 6mm, put an appropriate amount of glass beads (5 grams) at the bottom of the shaking container to assist emulsification, do not let the horn directly contact with the wall of the container, The rod is 20-30mm away from the bottom of the container, and the power of the u...

Embodiment 2

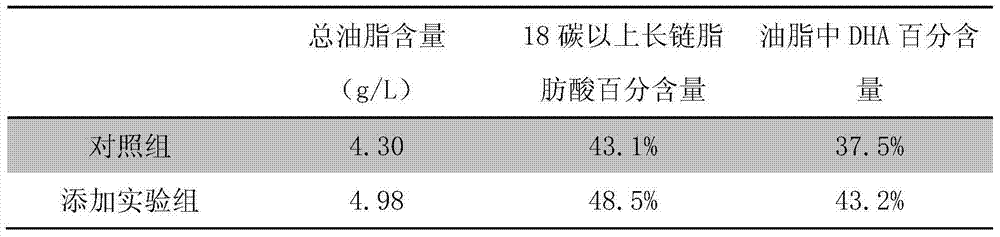

[0038] Use emulsified oleic acid as a fermentation additive

[0039] Oleic acid (molecular formula: C 18 h 34 o 2 ) Colorless oily liquid at room temperature (melting point 16.3°C), insoluble in water.

[0040] Take 500 ml of water, add 25 grams of liquid oleic acid, and then add 5 ml of rhamnosyl ester (food grade). Slowly heat to 90°C, use a general-purpose ultrasonic generator device, the diameter of the horn is about 6mm, put an appropriate amount of glass beads (5 grams) at the bottom of the shaking container to assist emulsification, do not let the horn directly contact with the wall of the container, The rod is 20-30mm from the bottom of the container, and the power of the ultrasonic transducer is set to 130W. During the cavitation process, the thermal effect causes the temperature to be too high to make the system boil, and emulsifies in short time intervals (working for 2 seconds and 2 seconds apart). Ultrasonic vibration treatment for 1 minute, the control tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com