System device and method for modifying coke oven gas to directly reduce iron ore

A coke oven gas and system device technology, applied in the direction of reducing gas emissions, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

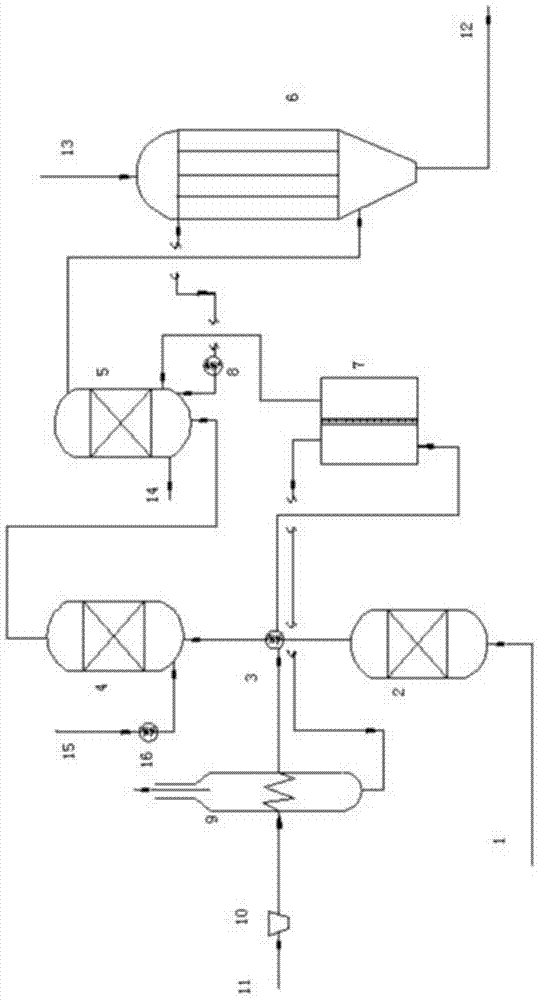

[0052] The low CO of this embodiment 2 For the system device and process flow of coke oven gas upgrading and direct reduction of iron ore, please refer to figure 1 .

[0053] The system equipment includes coke oven gas supply system, air supply system, oxygen separation system, high temperature desulfurization system, coke oven gas dry gasification cracking reaction system, coke oven gas reforming reaction system and iron ore direct reduction system; The structural composition of each system and the connection mode of the configured devices are as follows:

[0054] 1. Coke oven gas supply system: coke oven gas 1 is sent to the lower end of reforming reactor 5 through pipelines through high-temperature desulfurization reactor 2, heat exchanger 3, and dry gasification cracking reactor 4.

[0055] 2. Air supply system: The air 11 is delivered to the lower end of the oxygen separator 7 through the pipeline sequentially through the compressor 10, the waste heat recovery device 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com