Method for preparing electric silicon steel conductive metallographic phase sample

A sample preparation and sample technology, which is applied in the field of electrical silicon steel metallographic sample preparation, can solve the problems of material change, influence analysis results, long preparation time, etc., and achieve the effects of low cost, stable and reliable technology, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

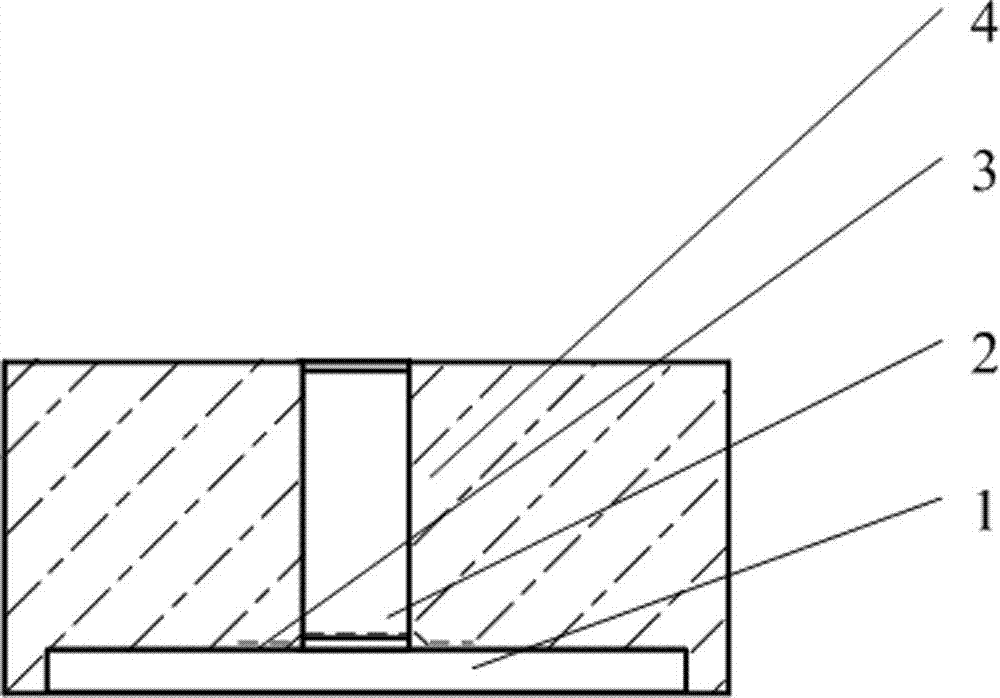

[0019] The invention provides a method for preparing a conductive metallographic sample of electrical silicon steel, the preparation steps of which are as follows:

[0020] ①Blanking and polishing the sample: punch sample 1 into a disc with a diameter of φ23㎜, and lightly polish one surface of sample 1 with 180Cw silicon carbide sandpaper or a file, so as to remove the insulating coating and expose the metal luster of the substrate. The area is 12㎜×12㎜;

[0021] ② Preparation of conductive electrodes: use 0.5mm thick and 6mm wide pure copper plates to press into such figure 1 , figure 2 For the concave conductive electrode 2 shown, the oxide layer on the surface of the copper plate can be lightly polished with 180Cw silicon carbide sandpaper;

[0022] ③Paste the conductive tape: place one end of the conductive electrode 2 vertically on the polished surface of the sample 1, and use a conductive tape 3 with a size of 8㎜×12㎜ to closely adhere the conductive electrode 2 to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com