Optical fiber probe with polarization maintaining characteristic and manufacturing method thereof

A fiber optic probe and polarization-maintaining optical fiber technology, which is applied in the field of weak optical signal detection, can solve the problems of reduced spatial resolution, signal light intensity, and signal-to-noise ratio, so as to increase radiation rate, eliminate polarization state changes, and improve The effect of the coherent signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the fiber optic probe with polarization-maintaining properties is specifically as follows:

[0037] (1) Select an elliptical-core polarization-maintaining fiber, cut it to a length of 12cm, remove the resin coating to obtain a bare fiber, and clean the bare fiber with alcohol and deionized water in sequence.

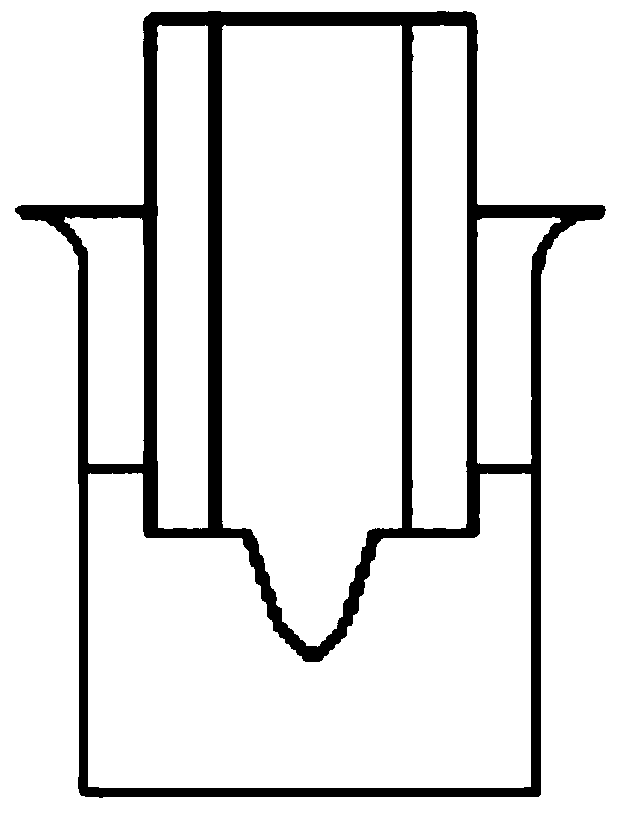

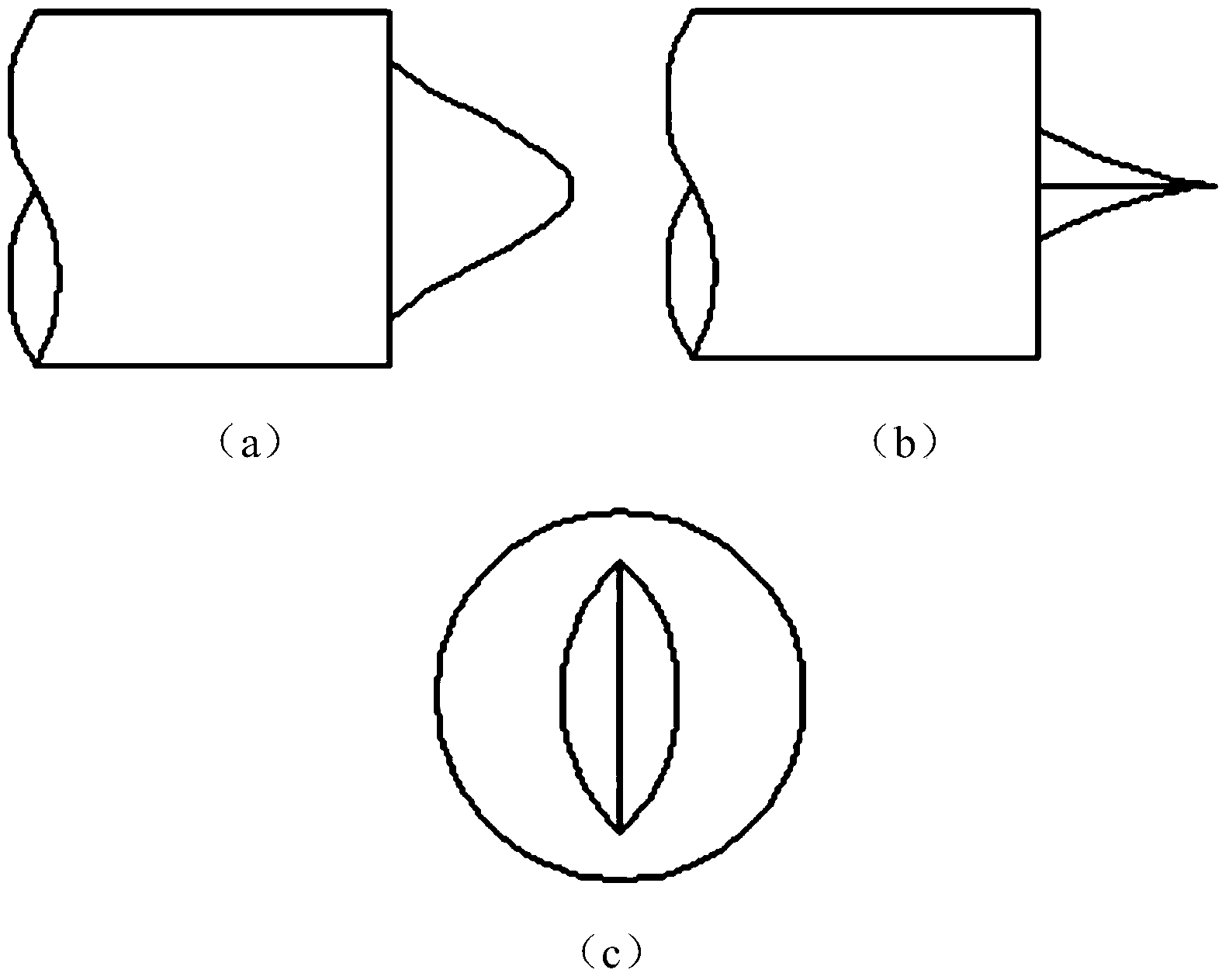

[0038] (2) Mix HF solution with a mass fraction of 40%, deionized water and NH4F solution with a mass fraction of 40% in a volume ratio of 3:5:40 to obtain an etching solution, and cover a layer of glycerin on the surface of the etching solution As the protective liquid, the thickness of the protective liquid was 2 mm. Such as figure 1 As shown, the bare optical fiber is inserted vertically into the etching solution, and the lower end of the optical fiber is exposed to the etching solution. After 10 hours of etching, a needle tip is formed. The needle point is duckbill-like, and the lower end surface of the needle point is elliptical. T...

Embodiment 2

[0044] The preparation method of the fiber optic probe with polarization-maintaining properties is specifically as follows:

[0045] (1) Select an elliptical-core polarization-maintaining fiber, cut it to a length of 10cm, remove the resin coating to obtain a bare fiber, and clean the bare fiber with alcohol and deionized water in sequence.

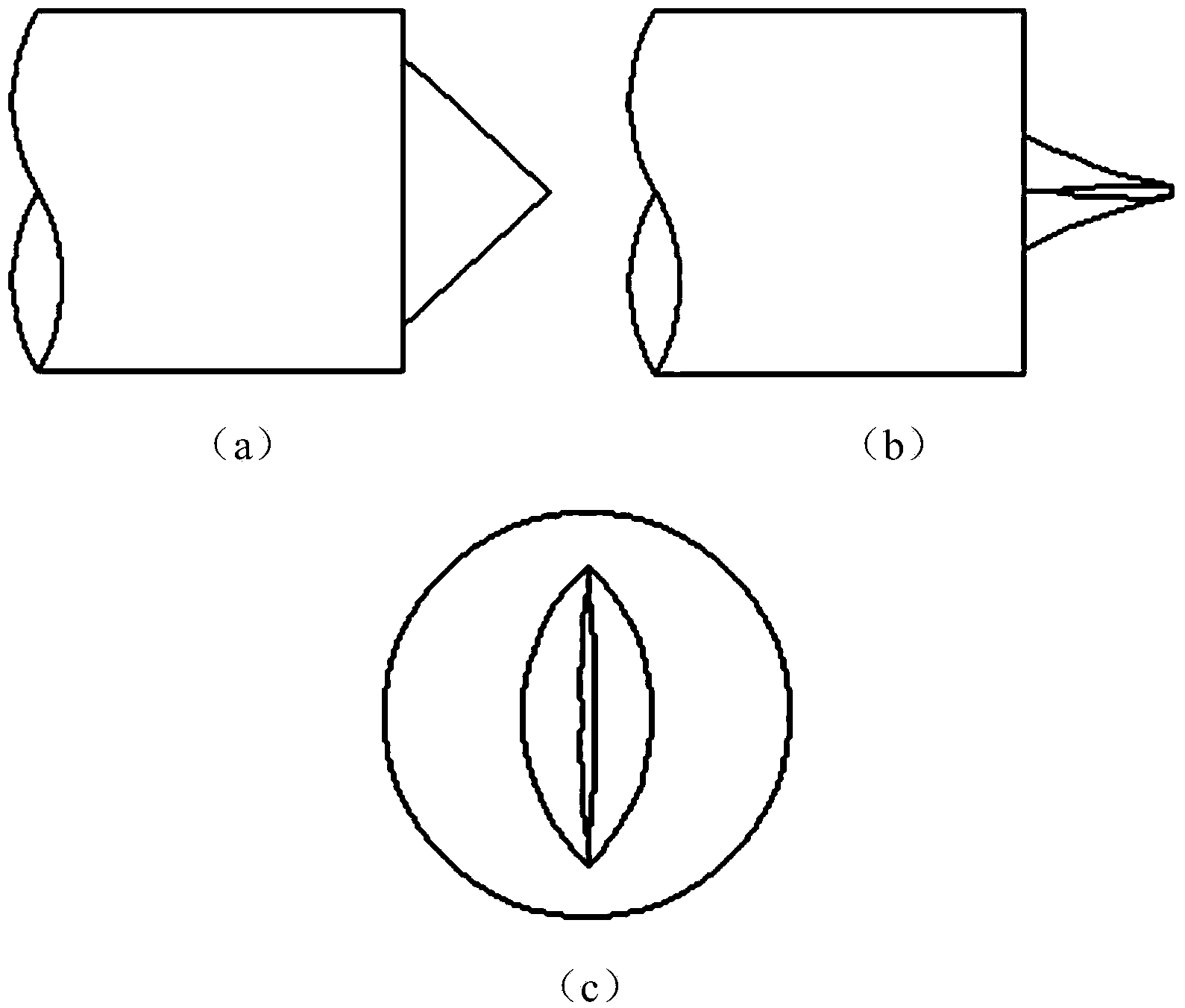

[0046] (2) Mix HF solution with a mass fraction of 40%, deionized water and NH4F solution with a mass fraction of 40% in a volume ratio of 3:5:40 to obtain an etching solution, and cover a layer of glycerin on the surface of the etching solution As the protective liquid, the thickness of the protective liquid was 2 mm. Insert the bare optical fiber part vertically into the etching solution, and expose the lower end of the optical fiber to the etching solution. After etching for 10 hours, a needle tip is formed. The needle point is duckbill-like, and the lower end surface of the needle point is elliptical. Two curved surfaces forming the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com