Method for improving quality of gate oxide

A gate oxide layer and high-temperature oxidation technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., to achieve the effects of inhibiting the growth of foreign oxide layers, reducing thickness, and reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

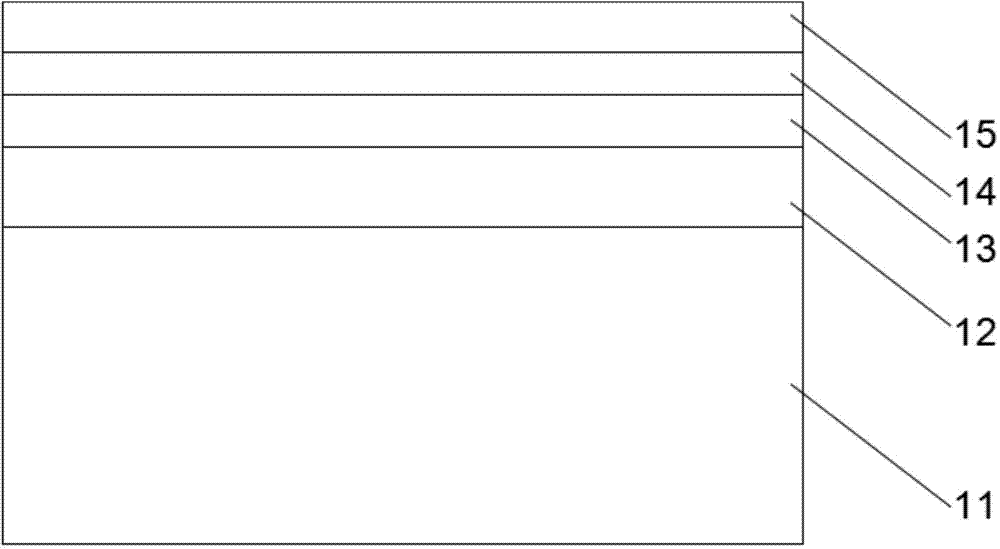

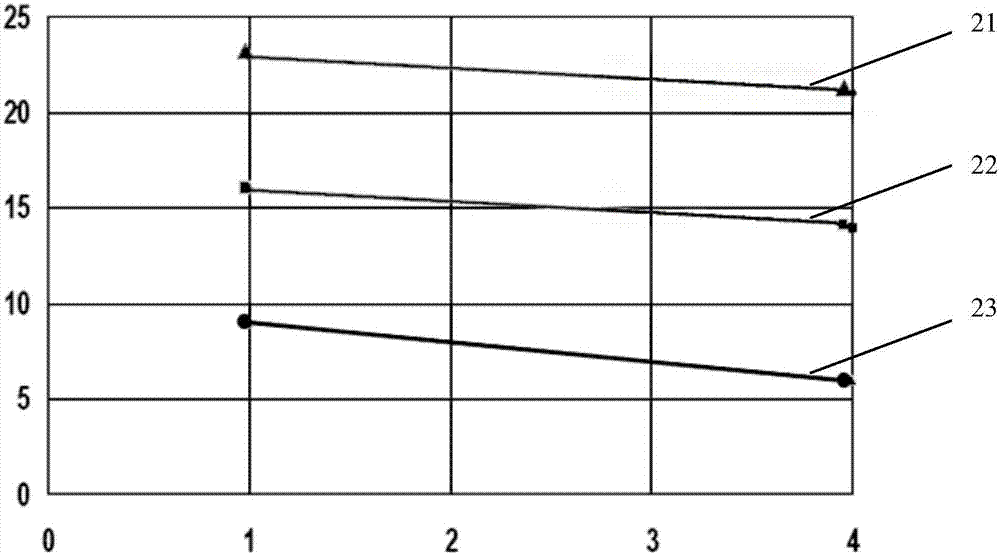

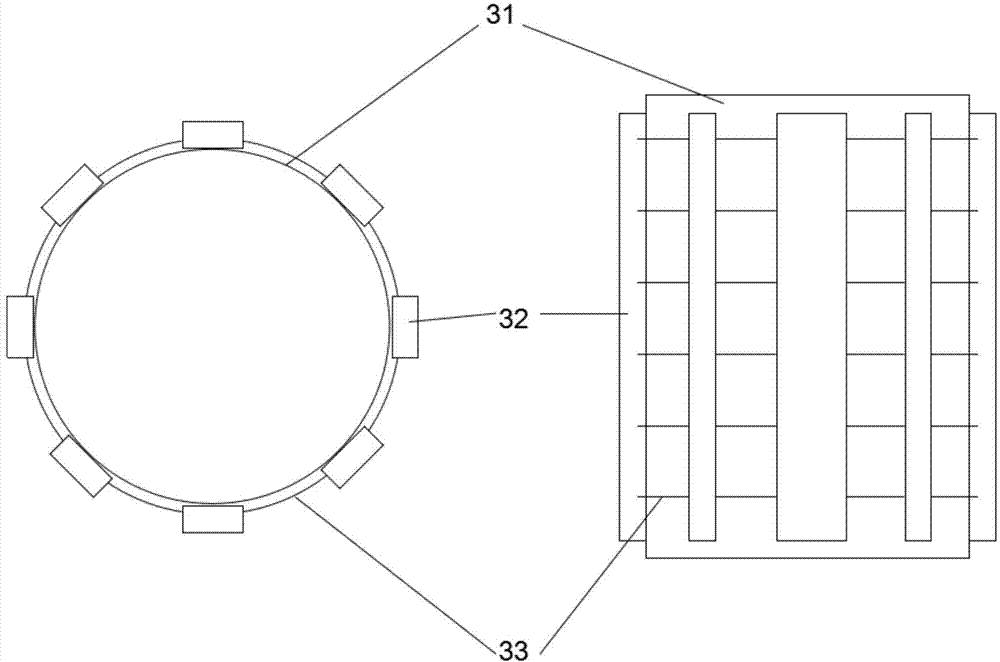

[0030] The core idea of the present invention is to realize faster heating and cooling control of the furnace tube by replacing the heating part of the furnace tube in the traditional process, that is, the alloy resistance wire, with a carbon fiber heating tube. At the same time, the waiting time for the crystal boat to rise and fall in the furnace tube is reduced, thereby reducing the growth time of the foreign oxide layer and further improving the quality of the gate oxide layer.

[0031] The specific embodiment of the present invention is:

[0032] A silicon substrate is provided, and the silicon substrate is first subjected to a wet cleaning process (using diluted HF as a cleaning solution) to remove the natural oxide layer formed on the surface of the silicon substrate, in order to prevent the silicon substrate from being exposed to oxygen in the air again A reaction occurs to form a natural oxide layer, so the silicon substrate is placed in the wafer boat and sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com