Phase-shift full-bridge converter circuit and control method

A technology of converting circuits and phase-shifting full bridges, applied in control/regulation systems, DC power input conversion to DC power output, electrical components, etc. Reduce the efficiency of the whole machine and other issues to achieve the effect of reducing the EMI of the whole machine, reducing switching losses, and improving the efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

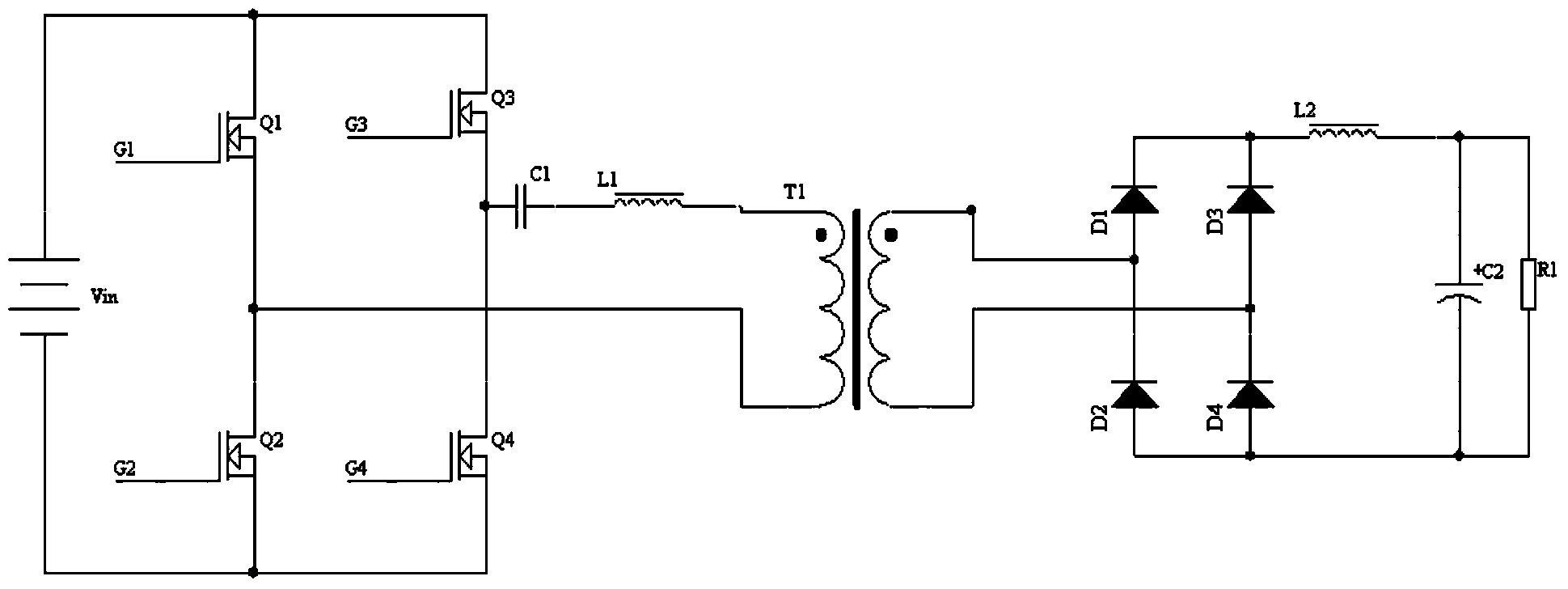

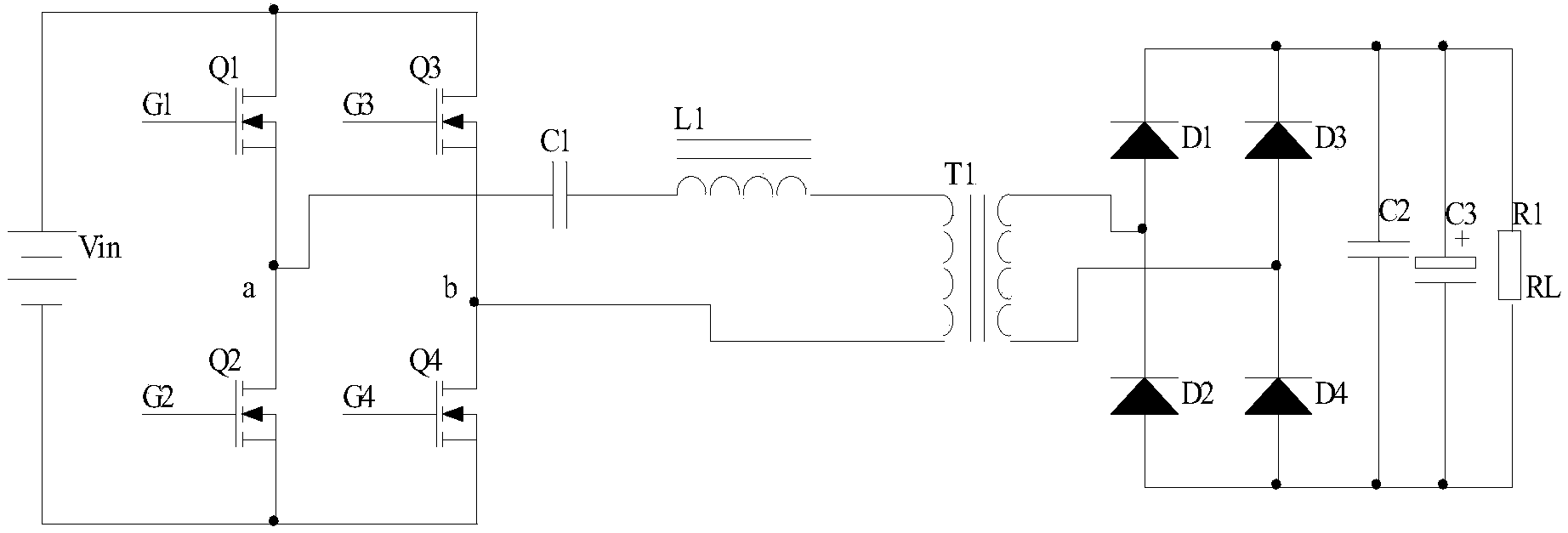

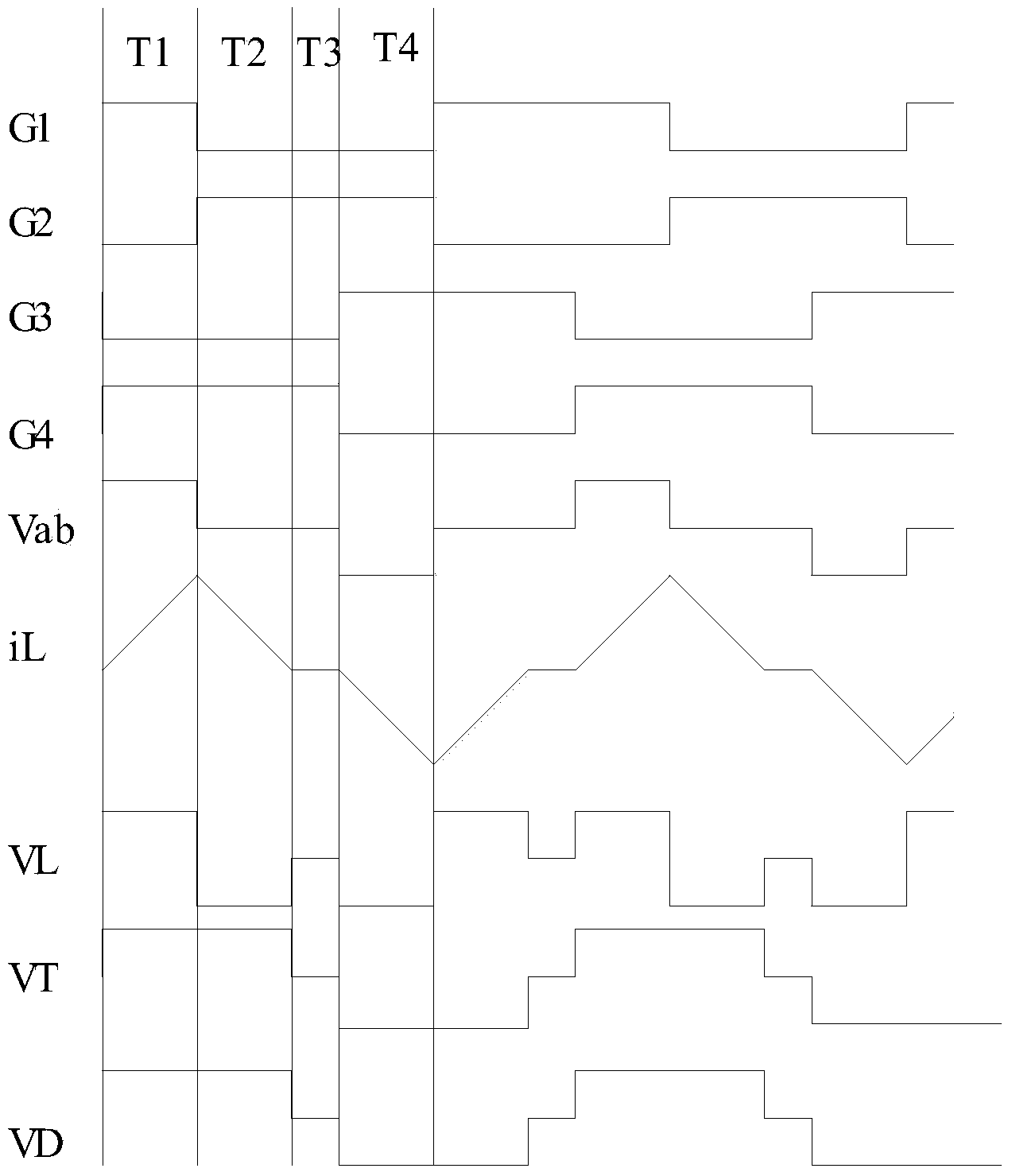

[0034] For the control method of the phase-shifted full-bridge conversion circuit of the present invention, see figure 2 and image 3 , a working cycle of the phase-shifted full-bridge conversion circuit is divided into the following stages: where, G1, G2, G3, and G4 are the applied grid voltages from MOS tube 1 to MOS tube 4 (Q1-Q4) respectively, and iL is the primary voltage of the transformer side resonant inductor L1 current, VL is the voltage of the resonant inductor L1, VT is the primary side voltage of the transformer T1, Vin is the input DC voltage, Vo is the output DC voltage, VD is figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com