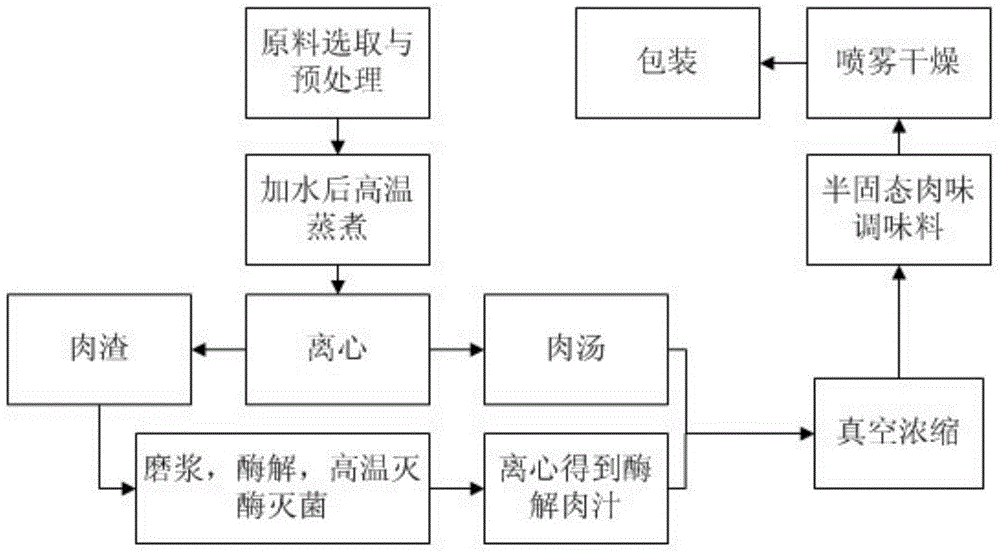

Preparation method of pure natural meat flavor seasoning

A seasoning, pure natural technology, applied in the field of preparation of pure natural meat seasoning, can solve the problem of inability to directional enzymolysis of protein, etc., and achieve the effects of improving product quality, increasing stability, and increasing width and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] After the live chicken is slaughtered, remove the feathers and viscera, freeze the whole chicken, weigh 100kg after freezing hard, crush it into 3mm meat pieces with a frozen meat crusher, then put it into a cooking pot, add 20kg of water, heat up to 100°C, and keep warm 5 hours, then carry out the soup slag separation with frame type centrifuge, rotating speed is 1000rpm, obtain chicken slag and chicken soup, put chicken soup into storage tank and store, chicken slag grinds into slurry with bone mud machine, puts into enzymolysis tank, Add 200kg of water, add 0.2kg of bromelain and 0.1kg of Novozymes flavored protease, keep warm at 40°C for enzymolysis to obtain an enzymolysis mixture (the liquid substance is enzymolysis gravy), take a sample every 30 minutes to measure the state of free amino acids in the enzymolysis gravy Nitrogen content, when the content of free amino acid nitrogen in the enzymolysis gravy reaches 2% of the dry matter weight of the enzymolysis mixtu...

Embodiment 2

[0031]Weigh 100kg of frozen beef, crush it into 10mm meat pieces with a frozen meat crusher, then put it into a cooking pot, add 50kg of water, heat up to 130°C, keep it warm for 1 hour, and then use a rack type centrifuge to separate the soup residue. The rotation speed is 1000rpm to obtain beef dregs and beef soup, put the beef broth into a storage tank for storage, grind the beef dregs into a slurry with a bone mud machine, put them into an enzymatic hydrolysis tank, add 100kg of water, add 2kg of bromelain, 1kg of Novozyme flavor Protease, heat preservation at 65°C to obtain enzymatic hydrolysis mixture (the liquid substance is enzymatic gravy), take a sample every 30 minutes to measure the content of free amino acid nitrogen in the enzymatic gravy, when the content of free amino acid nitrogen in the enzymatic gravy When the dry matter weight of the enzymolysis mixture reaches 4%, the temperature is raised to 95° C. and kept for 20 minutes to sterilize the enzyme. Separati...

Embodiment 3

[0034] Weigh 100kg of frozen headless prawns, crush them into 5mm meat pieces with a frozen meat crusher, then put them into a cooking pot, add 30kg of water, raise the temperature to 110°C, keep warm for 3 hours, and then use a rack type centrifuge to remove the soup dregs Separation, rotating speed is 1500rpm, obtain shrimp meat dregs and shrimp broth, put the shrimp broth into storage tank for storage, grind the shrimp meat dregs into a slurry with a bone mud machine, put them into an enzymatic hydrolysis tank, add 150kg of water, and add 1kg of bromelain , 0.5kg Novozymes flavored protease, heat-preserved and enzymolyzed at 50°C to obtain the enzymolysis mixture (the liquid substance is the enzymolysis gravy), take a sample every 30 minutes to measure the content of free amino acid nitrogen in the enzymolysis gravy, when the enzymolysis gravy When the content of free amino acid nitrogen in the medium reaches 3% of the dry matter weight of the enzymatic hydrolysis mixture, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com