Alcohol-soluble tea powder nutritive local-flavor sausage and manufacturing method thereof

A tea powder and flavor technology is applied in the field of alcohol-soluble tea powder nutrition flavor sausage and its production, which can solve the problems of high energy, loss of nutrients, change of original flavor, etc. The effect of reducing and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

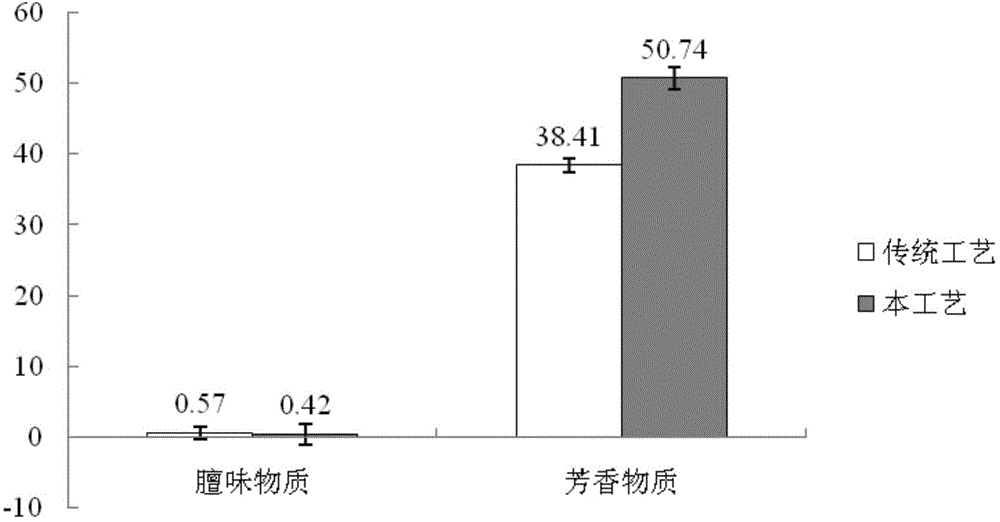

Image

Examples

Embodiment 1

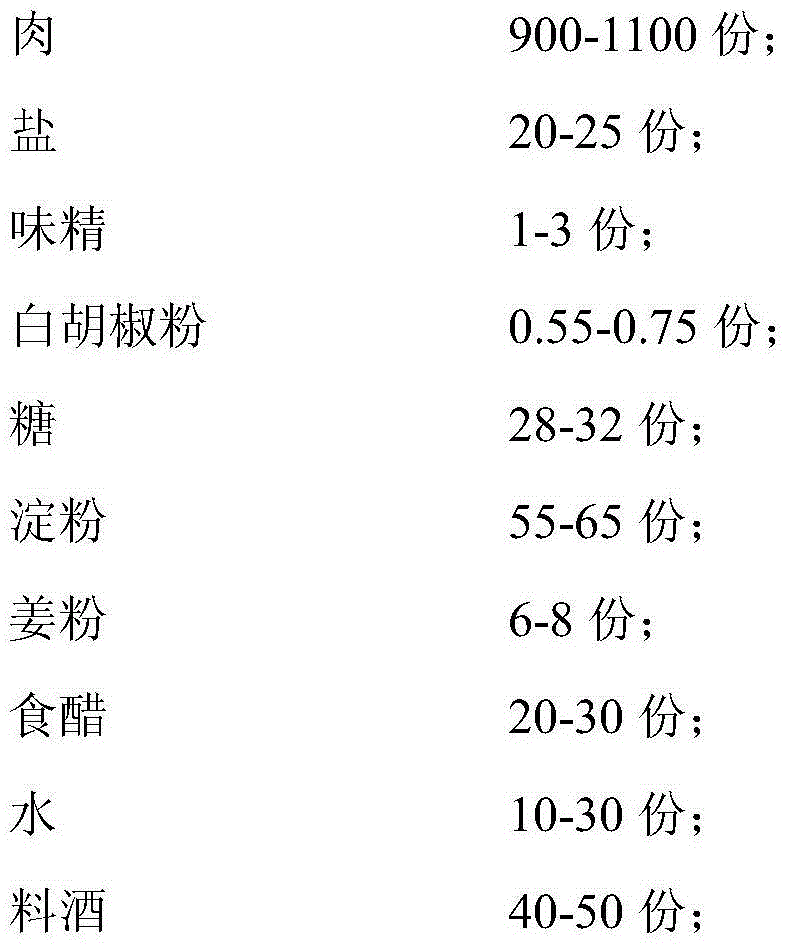

[0037] A black tea alcohol-soluble tea powder nutritious flavor sausage, its composition and parts by weight are as follows:

[0038]

[0039] The preparation method of the above-mentioned black tea flavor sausage comprises the following steps:

[0040] (1) Raw material pretreatment: wash the black tea tea dregs with distilled water, filter and leave the dregs, and freeze-dry at -54~-56°C and a vacuum of 627mbar;

[0041] (2) Extraction reaction: Add tea residue and ethanol with a concentration of 60% to 70% into the reaction kettle according to the ratio of solid to liquid g:mL of 1:10 to 1:20, and set the temperature at 65°C to 75°C. ℃, react for 60-80 minutes, release, and get a mixed liquid;

[0042] (3) Tea powder: Ultrafiltration is carried out on the mixed liquid, the set pressure is 0.1MPa, and the filtrate is obtained after ultrafiltration. Freeze-drying under the condition of 627mbar to obtain alcohol-soluble black tea powder;

[0043](4) Raw material processin...

Embodiment 2

[0050] A green tea alcohol-soluble tea powder nutritious flavor sausage, its composition and parts by weight are as follows:

[0051]

[0052] (1) Raw material pretreatment: wash the green tea tea dregs with distilled water, filter and leave the dregs, and freeze-dry at -54~-56°C and a vacuum of 627mbar;

[0053] (2) Extraction reaction: Add tea residue and ethanol with a concentration of 60% to 70% into the reaction kettle according to the ratio of solid to liquid g:mL of 1:10 to 1:20, and set the temperature at 65°C to 75°C. ℃, react for 60-80min, release;

[0054] (3) Tea powder: Ultrafiltration is performed on the mixed liquid, the set pressure is 0.1MPa, the filtrate is concentrated by suspension evaporation at 45-60°C and 0.1MPa, and freeze-dried at -54-56°C and vacuum degree of 627mbar to obtain Alcohol-soluble green tea powder;

[0055] (4) Raw material processing: wash the raw meat with water, peel off the skin, and cut into small pieces.

[0056] (5) Pickle and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com